Quantum dot solar cells and the search for stability

In various forms, quantum dot technology has attracted plenty of attention among PV researchers recently. And as efficiencies have crept past the 15% mark, the community is beginning to look at other factors limiting the viability of quantum dot solar cells in a commercial setting. Scientists in Germany examined the degradation mechanisms affecting different quantum dot materials; and suggest a standardization of stability testing to enable comparability of results.

Battery major Amara Raja plans 50 MW solar plant

The Indian automotive battery major has announced the setting up of a 50 MW solar power plant in Chittoor District of Andhra Pradesh. The plant—to be built at INR 220-crore investment—will help reduce the manufacturer’s carbon footprint while lowering its electricity bill. The firm, which has already set up a pilot plant facility for Lithium-ion cell development, is also mulling investments into energy storage for the renewables sector.

Modeling the potential of lead-free perovskites

Scientists in India modeled the performance of tin-based perovskite (methylammonium tin triiodide) finding that with careful optimizations the material could achieve efficiencies beyond 28%.

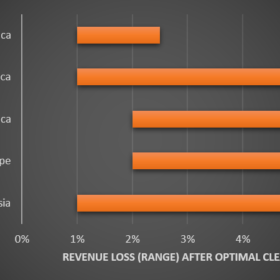

New model to predict PV module cleaning cycles and resulting profits

A group of scientists in Bangladesh has developed a model to determine the optimal cleaning schedule for a PV installation at any location in the globe, requiring only the average insolation and soiling rate for a given site to make the calculation. The study also draws new conclusions regarding the influence of sandstorms and rain on soiling, and aims to be among the first studies to paint a global picture of soiling trends by region.

New Premier solar factory to begin production by April

Indian solar manufacturer Premier Energies is setting up a factory in Telangana with an annual cell and module production capacity of 750 MW. The fab will be equipped to produce large-format panels with wafer sizes up to 210mm.

India eyes 10 GW of ingot-to-module solar factory capacity within two years

Under a production-linked incentive scheme, the government will reward manufacturers for building vertically integrated PV production lines. The scheme aims to attract 10 GW of production capacity by April 2023.

Waaree lithium batteries run electric forklifts at Chennai airport

The energy storage system arm of Waaree Group has designed and developed Lithium batteries to power ACE Ltd’s electric forklifts running at Chennai airport.

The long read: Circular innovations

Slowly but surely, environmental concerns are making their way into mainstream thought throughout the PV industry. A look at recycling offers an example of this, with stakeholders trying to get ahead of the high volumes of end-of-life modules already on the horizon. pv magazine examines the technologies that will be needed, alongside policy and economic support, to keep the bulk of these modules out of landfill and ultimately to establish a circular economy for PV materials.

Union budget: Customs duty rise for solar inverters but modules spared

Imported solar inverters and lanterns will get costlier, as the union budget for the next fiscal year has proposed customs duty increases from 5%, for both items, to 20% and 15%, respectively. The budget, which also incentivizes Indian manufacturing of solar project components whilst giving a helping hand to raw materials, makes no mention of solar cells or panels.

Panasonic to exit solar manufacturing

The Japanese brand will continue to sell third-party-made modules under its brand in its home market, as it already does overseas, but in-house PV wafer, cell and module production will halt by the end of fiscal year 2022.