Shipments of module-level power electronics could hit 100 GW by 2026

IHS Markit said it expects the United States, Germany, and the Netherlands to be the top three markets for cumulative shipments of module-level power electronics in the 2022-26 period. Cumulative shipments are set to hit almost 100 GW by 2026.

Bslbatt unveils 10.24 kWh battery for residential PV

China’s Bslbatt said its new battery has a rated capacity of 200 Ah. The product comes with a 10-year warranty and can reportedly provide steady operation for up to 6,000 charge cycles.

The long read: International investments in Indian PV

India is seeing massive investments in PV manufacturing, with manufacturers from Western countries, led by the United States, eager to get in on the act. Chinese companies have yet to make the same call, however.

Amp Energy to manufacture solar cells, modules

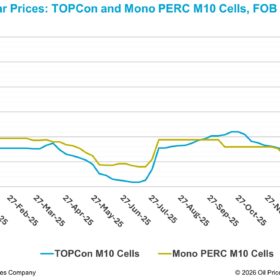

Amp Energy has agreed to partner with Websol Energy to produce up to 1.2 GW of monocrystalline PERC solar cells and modules.

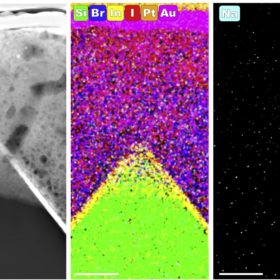

Solar perovskite tandems and potential-induced degradation

Scientists have found that perovskite solar cells and perovskite-silicon tandems might be vulnerable to potential-induced degradation. They exposed tandem cell devices to PID stress and found that they lost as much as 50% of their initial performance after just one day.

Premier Energies earns LEED Gold certification for its solar factory

The Indian manufacturer’s facility at Electronic City in Telangana has become the first LEED Gold-rated solar cell and module manufacturing facility in India. It received the stringent green building rating from the US Green Building Council.

Renon targets INR 40 crore of revenue in FY 2022-23

Renon India, an energy storage startup, has announced a new full-year revenue target, as well as plans to ramp up its annual lithium battery manufacturing capacity from 200 MWh to more than 500 MWh.

Making India a manufacturing hub for solar-based, decentralized energy products

A new report by GOGLA highlights the opportunities and challenges in establishing local manufacturing and assembly of solar-based decentralized energy solutions in India. It also explores the actions needed to maximize available opportunities.

Saatvik joins PV Cycle initiative for solar waste recycling

Indian manufacturer Saatvik has joined Belgium-based PV Cycle’s recycling scheme for damaged solar modules.

Solinteg launches new residential hybrid inverter series

Solinteg’s new hybrid inverters come in seven versions with nominal power ranging from 3 kW to 9 kW, an efficiency rating of 97.6%, and a European efficiency of 97.0%. They measure 534 mm × 418 mm × 210 mm and weigh 27 kg.