Optimizing photovoltaic systems: Best practices for economic, technical key performance indicators

As the global solar energy industry grows, so does the need for accurate monitoring of performance and financial viability. The latest report by IEA PVPS Task 13, “Best Practice Guidelines for the Use of Economic and Technical KPIs,” provides a comprehensive framework to address this issue. This article explores the importance, methodologies, and applications of Key Performance Indicators (KPIs), with a focus on their role in optimizing PV systems.

U.S. solar panel supply ‘sufficient’ but two bottlenecks hold industry back

Solar panel supply is no issue, but other installation bottlenecks have emerged, said a report from Clean Energy Associates.

Huasun debuts 720 W solar modules for vertical PV projects

Huasun has launched its 720 W Kunlun G12 dual-glass bifacial solar panels for vertical PV projects at the World Future Economic Summit in Abu Dhabi. The panels feature a 23.2% power conversion efficiency and enhanced mechanical stress resistance with a steel alloy frame.

U.S.-made perovskite-silicon tandem solar modules could be produced at around $0.35/W

Techno-economic analysis conducted by NREL researchers has shown how perovskite-silicon tandem solar modules could currently hardly compete in cost with incumbent PV panels. Production costs for U.S.-made tandem products were found to range between $0.29/W and $0.42/W, with module efficiencies ranging from 25% to 30%.

Field testing shows perovskite solar modules can retain 78% of their initial efficiency after one year

Researchers from Belgium and the University of Cyprus have completed outdoor stability tests of perovskite solar mini-modules providing two-years of data on stability performance. The tests showed that the modules’ performance loss rates during the burn-in period of perovskites ranged between 7% and 8% per month.

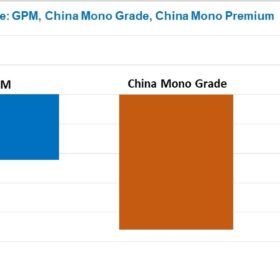

GPM awaits tariff support, Chinese polysilicon futures injects boost

In a new weekly update for pv magazine, OPIS, a Dow Jones company, provides a quick look at the main price trends in the global PV industry.

Jupiter International announces INR 6,500-crore plan for solar wafer-to-module manufacturing

Solar cell manufacturer Jupiter International plans manufacturing capacities of 3 GW for wafers, 9.4 GW for cells (including the existing 1 GW), and 6 GW for modules.

Vertical rooftop PV performs better than conventional rooftop solar under the snow

A case study analysis by Norway’s Over Easy Solar has found that vertical rooftop solar panels outperform conventional rooftop PV systems during snowy months. Energy yield was up to 30% higher in the winter months in Norway, according to the company.

Saatvik Green secures 1 GW solar module contract

Saatvik Green Energy has secured an INR 1,500-crore contract to supply 1 GW of n-type TOPCon solar PV modules.

Solex Energy reports 103% revenue growth for nine months ended December

Solex Energy Ltd, a Gujarat-based solar manufacturer and EPC solutions provider, has recorded consolidated revenue of INR 408 crore for the nine months ended Dec. 31, 2024