World could add more than 900 GW of solar by 2025 if politicians grasp the nettle – IEA

With the International Energy Agency publishing its latest five-year clean energy forecast today, pv magazine takes a look at the solar content of the 162-page document.

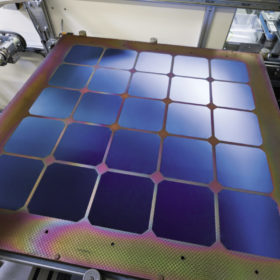

Waaree’s solar module testing lab becomes NABL accredited

The lab—located at Waaree’s factory in Gujarat—is the first such by an Indian module manufacturer and can perform more than 30 critical IEC tests.

The best PV module cooling technique

An international research team has analyzed all existing cooling technologies for PV panels and has indicated the current best options and future trends of research. According to its findings, active water cooling, although expensive and not particularly practical, is the most effective cooling technique while passive cooling systems, despite being easy to apply, have still limited possibilities.

REIL tenders for supply of 200,000 multi-crystalline silicon solar cells

Manufacturers are invited to supply 100,000 quantities of 4.5W (4-/5-busbar) and 4.60W (5-busbar) cells each. Bidding closes on November 3.

RenewSys launches 505Wp solar modules

The Indian solar manufacturer has unveiled the DESERV Galactic Ultra series, which features the world’s first mono-facial modules to cross a peak output of 500 W using G1-sized (158.75mm) cells.

REIL seeks bifacial and mono PERC solar cells

November 10 is the bidding deadline for the supply of 50,000 bifacial cells with a peak power rating of 5W and 100,000 mono PERC cells (50,000 of 7Wp and 10Wp each).

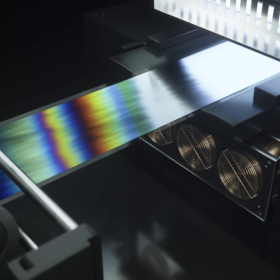

Conformity assessment of solar PV panels in India

Quality of testing is equally important even as new test labs come up for solar modules. Proper equipment selection and frequent calibration of equipment are prerequisites to ensure the credibility of the test results.

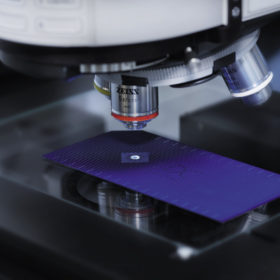

The long read: The cracks are showing

Finding tiny cracks in a silicon solar cell is not that easy, particularly given that these cracks initially have little or no effect on module performance. But a number of common occurrences in a module’s lifetime can cause cracks to grow, rendering whole areas of a cell useless. And this is increasingly being recognized as one of the most significant risks to module reliability – one which the PV industry is hard at work to mitigate.

Manufacturing a green solar bounce in India

The nation must look at innovative PV technologies that are low-cost and can be applied in a vast range of new applications.

PV module innovations to lower solar costs in coming decade

A new report by Wood Mackenzie suggests that rapid solar module technology innovations in the next decade will lead to significant increases in module power class, better performance and more versatile applications. Technology and lower capex will be key to sector growth, it adds.