Meyer Burger unveils new solar tiles

Meyer Burger plans to start selling a new building-integrated PV product from 2022. It says the solar tiles have a high energy yield, with simplified installation and the ability to also provide heating. German engineering company paXos designed the tiles.

JinkoSolar sets new record for n-type solar cell efficiency

Manufacturing giant JinkoSolar has set another world record for n-type solar cell efficiencies with its TOPCon technology, this time pushing to 25.4%. The new world record was confirmed by JET laboratories in Japan, and surpasses JinkoSolar’s previous record of 25.25% set back in May.

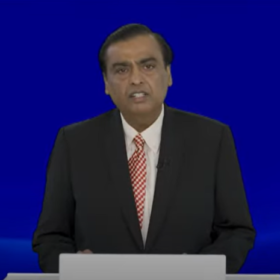

Reliance New Energy Solar to invest $29 million in German wafer manufacturer NexWafe

The Reliance Industries Ltd arm, which plans solar gigafabs in Gujarat, has raised a stake in German wafer manufacturer NexWafe with an investment of EUR 25 million ($29 million).

India and Australia’s richest race to net-zero by 2030

Today, both Reliance and Fortescue are realizing the huge investment, employment, import replacement and export opportunities in zero emissions industries of the future, both for India and Australia. And they look to be leading the way, fully supported by global financial institutions increasingly seeking to deploy trillions of patient capital in low volatility, non-commodity price exposed zero-emissions energy sources of the future.

Reliance Industries acquires 100% stake in REC Group, plans new manufacturing bases

India headquartered multinational Reliance Industries, through its subsidiary Reliance New Energy Solar Limited, yesterday announced the acquisition of Norway headquartered module manufacturer REC Group. The move comes as Reliance pushes forward with its US$10 billion plan to move in on the renewable energy industry, having also this week announced acquisition of a 40% share in EPC provider Sterling & Wilson.

Risen showcases n-type solar panel with output of 700 W

The 210 mm module can reach a power output of up to 703.6 W and a power conversion efficiency of 23.08%. The result was confirmed by Germany’s TÜV SÜD.

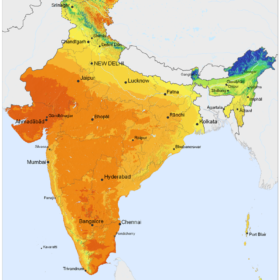

The long read: First Solar – ‘India presents a big market opportunity for us’

Sujoy Ghosh, First Solar’s vice president for India and the Asia-Pacific region, speaks to pv magazine about the company’s plans to set up a 3.3 GW module fab in India to service the local market.

Emerging trends in the Indian solar power sector

The Indian solar power sector is undergoing a technology-backed transformation at every stage from manufacturing to installation to improve cost and performance efficiency.

Vietnamese manufacturer unveils PV module for agrivoltaics

Vietnamese manufacturer Irex has announced a new glass-glass solar panel with a power output of 265 W and a power conversion efficiency of 18.1%.

Silicon metal and aluminum industries hit by China power shortages

A combination of booming demand for coal-fired power and a shortage of the black stuff – exacerbated by a political row with Australia – have forced up prices to the extent fossil fuel generators are making a loss on every unit of electricity they produce. pv magazine‘s Vincent Shaw considers the potential solutions.