New water-draining device for rooftop PV systems

Portuguese startup Solarud has developed a way to eliminate soiling around the frames of PV panels with low inclination slopes. The device drains water that would otherwise stay stagnant on the surface of modules.

Saatvik launches 545 W bifacial PV modules

Indian manufacturer Saatvik has developed bifacial PV modules based on mono PERC, half-cut technology. The multi-busbar modules boast an efficiency rating of 21.12%.

Waaree supplies 45 MW of PV modules to KPI Global

Mumbai-headquartered Waaree has supplied its 335 Wp polysilicon modules to Gujarat-based developer KPI Global Infrastructure, for projects in Bharuch district, Gujarat.

Solar briefcase packs in 200 W for off-grid, mobile living

FlexSolar has developed a foldable, portable PV briefcase kit with a charge controller and connection cables.

India to lead new energy wave

A new report from the Institute for Energy Economics and Financial Analysis (IEEFA) tracks key trends at major companies across India’s power sector value chain. It finds the nation is poised to lead the clean energy wave, with investors committing in response to the bold policies that are enabling the transition.

Sharp launches 540 W bifacial solar module

Sharp’s new IEC 61215 and IEC 61730-certified-certified panel features 144 half-cells based on M10 wafers and a 10-busbar design. Its operating temperature coefficient is -0.349% per degree Celsius and its power tolerance reaches up to 5%.

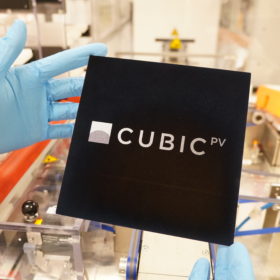

CubicPV, Waaree sign five-year deal for annual solar cell supply of 1 GW

USA-headquartered CubicPV will supply, per annum, 1 GW of Direct Wafer silicon solar cells to Indian manufacturer Waaree Energies under a five-year contract. The cells will be supplied from its upcoming 2 GW factory in India.

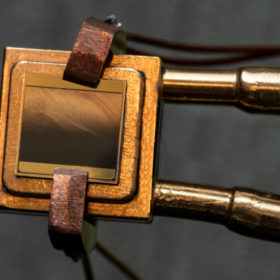

MIT, NREL researchers develop 40%-efficient thermophotovoltaic cell for grid-scale thermal batteries

The device is described as a heat engine with no moving parts that is able to produce power from a heat source of between 1,900 to 2,400 C. This concept is known as thermal energy grid storage (TEGS) and consists of a low-cost, grid-scale storage technology that uses thermophotovoltaic cells to convert heat to electricity above 2,000 C.

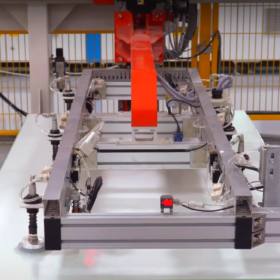

Mobile agrivoltaic system from the Netherlands

Created by a Dutch group of companies and research institutions, the mobile solar system may also be combined with an electrolyzer for hydrogen generation. Two prototypes are currently being tested by a farmer and a research institute in the Netherlands.

Growatt unveils solar rechargeable portable power station

Chinese inverter maker Growatt has launched Infinity 1500, a portable power station for off-grid applications.