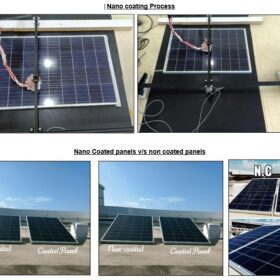

New nanocoating to improve solar module output

India’s TriNANO Technologies has developed a nanocoating for solar modules that reportedly increases the panel’s power generation by up to 4% owing to its light trapping, anti-reflection and self-cleaning properties. It also lowers the panel temperature by 2-3 degrees Celsius compared to non-coated panels.

All solar cell efficiencies at a glance – updated

The research group led by Professor Martin Green has published Version 62 of the solar cell efficiency tables. There are 21 new results reported in the new version, a record number for the Tables.

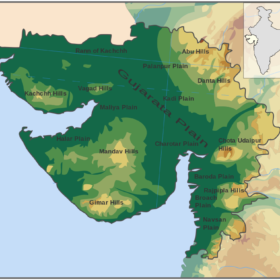

Insolation Energy plans 600 MW solar cell manufacturing facility

The Rajasthan-based solar module manufacturer is setting up a 600 MW PV cell production facility. It is also expanding its panel production capacity to 1.2 GW from the current 700 MW.

Solar-driven photoreactors to generate hydrogen on rooftops

Scientists led by the Karlsruhe Institute of Technology have designed panel-like photoreactors relying on a water-splitting photocatalyst that could produce hydrogen on rooftops or dedicated solar farms. They claim the photoreactors have high economic potential because of their ‘extremely’ low costs.

Germany seeking proposals for 10 GW of solar factories

Solar manufacturers have until Aug. 15 to submit PV factory proposals to the German authorities.

Solar passports to support PV waste management in India

A new study proposes a blockchain-based solar passports framework to address the PV waste management challenge in India. It says such a framework would enable transparent tracking and verification of PV panels throughout their lifecycle, ensuring efficient asset monetization and promoting sustainable practices within the solar industry.

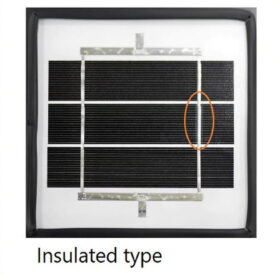

New technique to repair solder interconnection failures in solar panels

Researchers in Japan have developed a repair technique for solar modules with damaged busbars and solder ribbons. They claim the new method can be implemented on site, without removing the panels from the array.

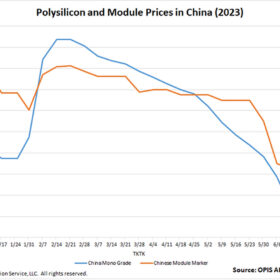

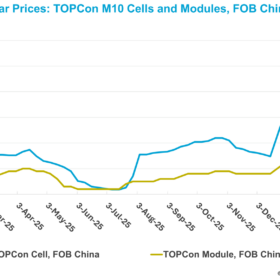

China solar module prices keep diving

In a new weekly update for pv magazine, OPIS, a Dow Jones company, provides a quick look at the main price trends in the global PV industry.

‘Oversupply is a natural challenge to our industry,’ says Trina Solar official

Helena Li, president of Trina Solar’s global cell and module business, spoke to pv magazine at the recent SNEC trade show in Shanghai about the PV industry’s oversupply challenge. Li said the company is considering opening a factory in Europe and expressed optimism about future cost and price declines.

Vikram Solar, Phalanx Impact and Das & Co form JV for ingot-to-module manufacturing in USA

India’s Vikram Solar and New York-based private equity firm Phalanx Impact Partners and investment advisor Das & Co. have formed a joint venture to establish 4 GW of ingot-to-module manufacturing operations in the USA with a planned investment of up to $1.5 billion.