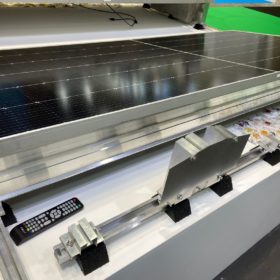

Mounting system for rooftop PV relying on large-size solar modules

Developed by Spanish manufacturer Alusín Solar, the new mounting system is claimed to be, currently, the only one on the market that provides six fixing points for a solar panel in ballast-secured structures.

Tata Power awarded India’s largest solar and battery storage project

Tata Power Solar has secured the engineering, procurement, and construction contract for a 100 MW solar field with a 120 MWh battery. The project, awarded by the Solar Energy Corporation of India, will be in Chhattisgarh.

Hindustan Salts Limited tenders 5 GW of solar in Rajasthan and Gujarat

The State-owned salt producer has invited developers to build and operate an aggregate 5 GW of solar capacity on its disused land in the Indian States of Rajasthan (4 GW) and Gujarat (1 GW). The developer shall pay to Hindustan Salts a fixed annual rental for the land provided on a per acre basis. Developers have until December 13 to lodge their interest.

Your next package delivery could be solar powered

There is still much to debate over the benefits of moving a vehicle via solar, but the market has been getting creative and is evolving quickly.

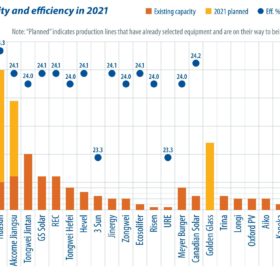

Looking past PERC solar cells

While the adoption of large-format wafers has driven a wave of capacity expansion for PERC, existing manufacturers and new entrants continue to evaluate TOPCon and HJT. An increasing number of HJT pilot lines and gigawatt-scale capacity expansion projects are appearing, as manufacturers see the advantages of fewer process steps, higher efficiency ratings, and better yield rates. The localization of equipment is also a driving factor. PV InfoLink’s Derek Zhao offers an update on the latest developments and process routes for HJT.

India added 2 GW of utility-scale solar in Q3 CY2021

JMK Research analysts expect the solar installation activity to further pick up in the fourth quarter. They estimate around 3.5 GW of new utility-scale solar capacity and 1 GW of hybrid capacity addition in the October-November-December period.

The outlook for residential rooftop solar in India

After stagnant annual growth for a couple of years, the rooftop PV market is showing signs of improvement with the usual obstacles no longer so daunting.

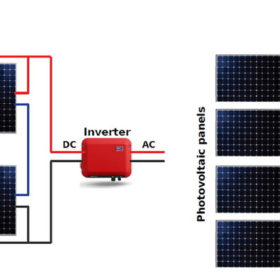

Micro-inverters vs. string/central inverters

A French research group has compared the performance ratio of 100 PV systems relying on micro-inverters with that of 100 installations relying on string/central inverters. It found the performance ratio is around 79% for both system typologies and that arrays with micro-inverters are more sensitive to environmental factors.

Central Electronics Limited tenders 95 MW of solar sites in Maharashtra

The successful contractor will install the arrays in blocks of 2-10 MW and will carry out all stages of installation, from site surveys through to 12 years’ operation and maintenance.

ARCI signs lithium battery technology transfer pact with Nsure

The R&D center under the Department of Science and Technology has indigenously developed lithium battery cells and packs for application in two-wheelers and solar street lamps.