Huge opportunity for module-level power electronics

A new report form analysts at IHS Markit notes that the market for module-level power electronics (MLPE) grew by 33% between 2019 and 2021, with around one-third of new residential solar installations now taking advantage of MLPE’s promise of improved safety, energy yield and fault detection. And with smaller, distributed generation systems expected to represent 43% of global PV installations between now and 2025, the opportunity for MLPE will only get larger.

Monitoring degradation for 13 module types

In a study that began in 2016, US scientists purchased 834 PV modules, representing seven manufacturers and 13 module types, and installed them in various climate conditions to observe their performance over time. The results show that, while plenty of opportunities still exist to extend module lifetimes and reduce performance loss in the field, reductions in the manufacturing cost of PV have not come with an increase in their degradation rate.

The long read: Open opportunity for PERC solar cell laser processing

Laser contact opening (LCO), a standard process in PERC cell production, has seen little market development in the past few years. Stiff competition from equipment suppliers in Asia, combined with the fact that most new n-type manufacturing doesn’t make use of LCO, has kept the level of interest here quite low. However, as the PV research community increases its focus on reducing silver consumption, new approaches to cell contacting and metallization provide impetus for a second look at laser processing.

Study finds 100% renewables would pay off within 6 years

New research from Stanford University researcher Mark Jacobson outlines how 145 countries could meet 100% of their business-as-usual energy needs with wind, water, solar and energy storage. The study finds that in all the countries considered, lower-cost energy and other benefits mean the required investment for transition is paid off within six years. The study also estimates that worldwide, such a transition would create 28 million more jobs than it lost.

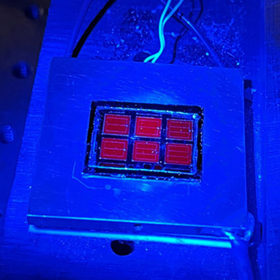

Quantum well superlattices for a new world record cell efficiency of 39.5%

Scientists in the United States have fabricated a triple-junction solar cell that reached 39.5% efficiency – a world record for any type of cell under one-sun illumination. Though relying on materials and processes that are still too costly for most commercial uses, the concept could soon see actual applications in powering satellites and other space-bound technology.

The long read: The right time for TOPCon

The potential advantages of n-type technologies have long been known to solar manufacturers, and such applications have been the focus of much of their research and development activities. Recent developments see 2022 shaping up as the year when n-type goes into mass production, led by tunnel oxide passivated contact (TOPCon) cells. pv magazine takes a closer at this cell technology and its route to the mainstream.

IEA outlines plan to rapidly reduce dominant role of Russia in Europe’s energy markets

The International Energy Agency has published a 10-point plan for Europe to reduce its reliance on natural gas imported from Russia. The plan would see Russian gas imports to EU member states reduced by one third within a year, and notes that further reductions within this timeframe would come with significant tradeoffs, likely to impact both energy prices and Europe’s Green Deal. The plan was presented by Fatih Birol, executive director of the IEA, in a virtual press conference held earlier today.

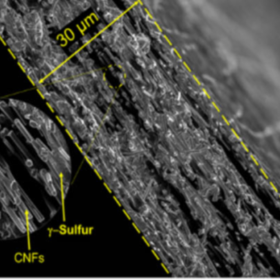

A 4,000 cycle lithium-sulfur battery

Scientists in the United States developed a lithium-sulfur battery using a commercially available carbonate electrolyte, that retained more than 80% of its initial capacity after 4000 cycles. The group used a vapor deposition process which unexpectedly produced a form of sulfur that did not react with the electrolyte, overcoming one of the key challenges for this battery chemistry.

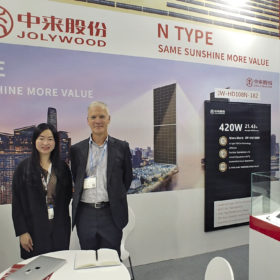

The long read: Expansions in n-type solar tech

The past 12 months have been a turbulent time for PV manufacturing. Rapid and impressive developments in technology have been accompanied by price increases up and down the supply chain, and energy shortages weighed on production in the second half of the year. Chinese n-type module manufacturer Jolywood is now pressing ahead with ambitious expansion plans despite the disruption. pv magazine publisher Eckhart K. Gouras and editor Mark Hutchins recently caught up with Cathy Huang, European sales director at Jolywood, to discuss the company’s plans to bring n-type TOPCon technology into mainstream production.

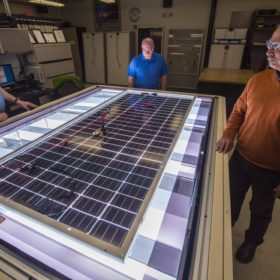

The long read: Finding PV faults faster

PV cell and module manufacturers are increasingly turning to artificial intelligence to monitor production lines and the products coming off them in minute detail. As inline monitoring and testing equipment become more sophisticated, cell and module makers must be prepared to manage the enormous amounts of data and pull out the points that will save them time and money. pv magazine examines the software solutions backing state-of-the-art PV production.