Saudi Arabia could hit net-zero emissions by 2060, with 151 GW of solar

Saudi researchers outlined pathways for Saudi Arabia to reach net-zero power sector emissions by 2060, requiring up to 3.6% of land – mostly for onshore wind – with 151.3 GW of solar PV covering only 0.16% of the country.

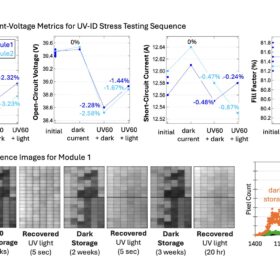

NREL researchers quantify UV-induced degradation levels in TOPCon solar cells

Researchers at NREL found that UV exposure can cause significant, partly non-recoverable degradation in TOPCon solar cells, with strong cell-to-cell and intra-cell variability linked to passivation and processing inconsistencies. While some UV-related losses recover quickly under light and are unlikely to affect field performance, the findings highlight gaps in current qualification tests and the need for improved UV aging standards.

WTO finds US clean energy tax credits violate trade rules

The WTO ruled that U.S. clean energy tax credits under the Inflation Reduction Act violate international trade rules by giving domestic products preferential treatment over Chinese goods. The decision specifically targets the ITC and PTC Domestic Content Bonus Credits.

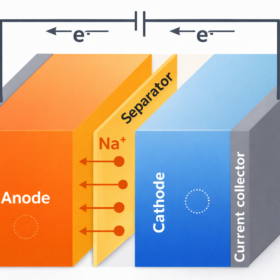

Sodium-ion batteries now competitive in niche markets

Sodium‑ion batteries are emerging as a safer, lower-cost alternative to lithium‑ion, with a recent international study highlighting their competitiveness in stationary energy storage. The research shows that ongoing investment and supply-chain development could enable broader adoption within the next decade.

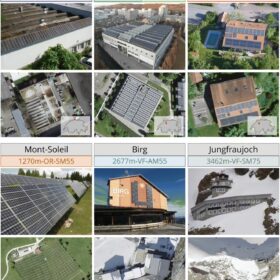

Study finds much lower-than-expected degradation in 1980s and 1990s solar modules

Researchers at SUPSI found that six Swiss PV systems installed in the late 1980s and early 1990s show exceptionally low degradation rates of just 0.16% to 0.24% per year after more than 30 years of operation. The study shows that thermal stress, ventilation, and material design play a greater role in long-term module reliability than altitude or irradiance alone.

Analysts warn of possible, sudden silver price fall

pv magazine has spoken with silver analysts from Bloomberg and StoneX about the vertiginous growth of silver prices in recent weeks. They both agree that when prices rise too fast, investors’ behavior may change quickly. Meanwhile, the price of the precious metal has reached another all-time high today at $110 per ounce.

Scientists design low-cost sodium-ion battery with cheap electrode materials

Conceived for stationary energy storage, the proposed sodium-ion battery configuration relies on an P2-type cathode material and an hard carbon anode material that reportedly ensure full-cell performance. Electrochemical testing revealed initial capacities of 200 mAh/g for the cathode and 360 mAh/g for the anode with capacity retentions of 42% and 67.4% after 100 cycles.

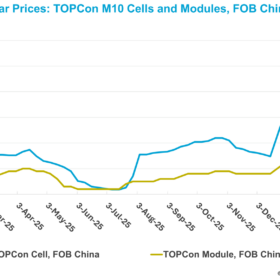

China PV module prices expected to hit $0.12/W in H2

China’s PV module prices are expected to hover around $0.12/W in the second half of 2026 as the removal of export VAT rebates, front-loaded demand, and persistent oversupply keep market sentiment volatile.

French scientists discover new UV-induced degradation pathways in heterojunction solar cells

Scientists from French research institute CEA-Liten have identified hydrogen migration in doped selective layers as the primary driver of UV-induced degradation in silicon heterojunction solar cells. They have also found that combined light and thermal light-soaking treatments can partially restore performance and improve long-term UV stability.

Canadian Solar wins U.S. patent litigation against Maxeon

The patent infringement case was related to an unspecified TOPCon solar cell technology.