From pv magazine France

After five years of research and a €15 million ($17.3 million) investment, steelmaker ArcelorMittal has inaugurated a production line for its Helioroof building-integrated photovoltaic (BIPV) system in Contrisson, in France’s Grand Est region.

Helioroof combines steel roofing, thermal insulation, and photovoltaic generation in a single, ready-to-install product for roofs with slopes of 7% or more. “Rooftop solar must become the norm. Helioroof allows us to combine two worlds: roofing and solar,” said Renaud Vignal, director of Helioroof at ArcelorMittal Building Solutions, at the Oct. 9 event.

The product uses two steel sheets with an insulating layer in between, while the top sheet integrates the solar cells. Custom-made panels can measure up to 12 meters in length, with energy outputs from 310 Wp to 2.1 kW per module.

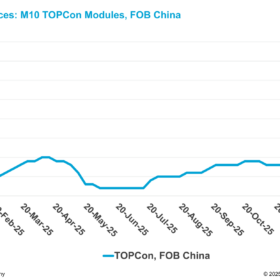

Production begins with coils of X-Carb low-carbon coated steel, which are unrolled and cut to order. Processing takes place in a “gray room” inside the plant to protect the solar cells. The TOPCon M10 cells, featuring 16 busbars and 25.4% efficiency, are supplied by unspecified Asian partners, and are welded, strung, and laminated directly onto the Eklipstherm sandwich panels.

The process is protected by 15 patents, according to Vignal. The line is now in scale-up, with potential capacity of 200,000 square meters of Helioroof per year – equivalent to roughly 80 MW – depending on market demand.

ArcelorMittal is targeting new and renovated residential, commercial, and industrial roofs, especially those undergoing asbestos removal. With no glass or mounting frames, Helioroof is said to be 50% lighter than conventional systems. The solar layer adds only 2.5 kg/m², compared with 12 kg/m² for standard PV modules. Depending on insulation thickness, the full system weighs between 13.5 and 17.5 kg/m².

“This considerably reduces the structural load on the building,” Vignal said.

The product also aims to cut installation time. It reportedly requires only one intervention instead of two, reducing installation time by 40% compared with conventional systems.

All electrical connections are located inside the building, minimizing risks of leaks or electrical faults. The system features two MC4 connectors in an integrated cable tray accessible from inside. It does not require an external electrical layout. A section of the Contrisson site has been dedicated to installer training.

Commercial production has begun. The first projects using Helioroof total 1,500 square meters, including an urban brewery in Liège, Belgium; a low-energy single-family home in France’s Marne region; and two industrial halls in Haut-Rhin and Meuse.

Using low-carbon steel and omitting glass and frames, ArcelorMittal claims Helioroof’s CO₂ footprint is 25% lower than that of conventional systems combining sandwich panels and rooftop PV. A full life cycle assessment is under way to quantify emissions.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.