Replacing conventional solar panel glass with polymeric materials can reduce weight, avoid glass breakage, and unlock new PV applications where low weight is a key requirement, such as building-integrated (BIPV) and vehicle-integrated photovoltaics (VIPV).

Alternative materials, such as polycarbonate sheets (PC), merit consideration according to “Lightweight Photovoltaics Enabled by Polycarbonate-Based Sheets,” a review published in Advanced Engineering Materials by researchers at King Abdullah University of Science and Technology (KAUST) in Saudi Arabia.

“Our review covered both new concepts for glass-free module designs and existing commercial solutions,” first author Marco Marengo told pv magazine, adding that PC was worth a second look in light of its proven performance outdoors in other fields of application.

Examples of outdoor applications are greenhouse roofing material, architectural skylights, and building facades. It is used due to its impact strength, broad operating temperature range, excellent dimensional stability, and self-extinguishing properties, according to the paper.

Furthermore, PC sheets offer a “unique combination” of low weight, mechanical strength, broadband optical transparency, and thermal resistance.

“Initially, we were doubtful about the possibility of implementing PC as a replacement for glass in PV modules. However, during our research, we realized that only a few material combinations were explored for lightweight PV, and several companies had already investigated PC-based modules,” said Marengo.

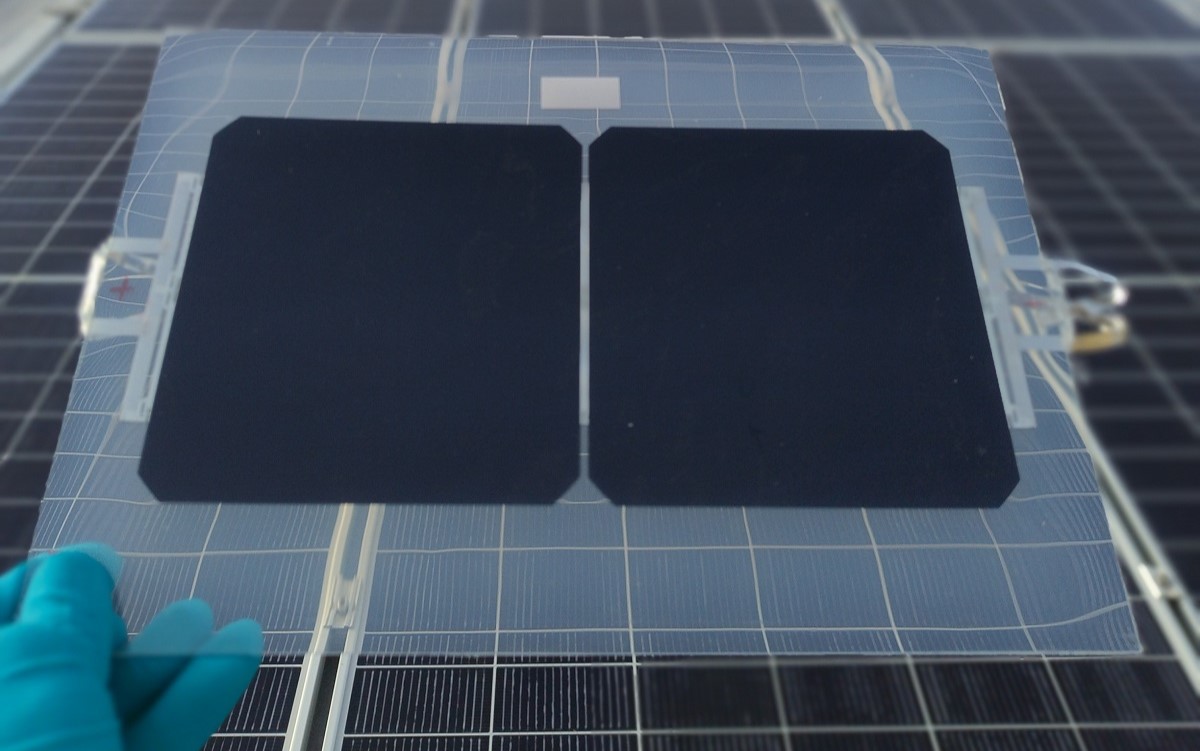

The focus of the study was on two thicknesses of PC sheets : (i) thin, less than 1 mm, flexible back and front sheets and (ii) thick, greater than 1 mm, rigid polymeric sheets. In the study, the researchers also compared glass properties, PC, and polymethyl methacrylate (PMMA) material properties, including cost.

The research indicated challenges to widespread adoption concern thermomechanical stresses “induced by different coefficients of thermal expansion in the materials stack,” compatibility with commercial encapsulants that are not necessarily tailored for adhesion to PC sheets and potentially higher costs. “However, recent advancements in encapsulation materials and solar cell interconnect designs offer promising solutions to these hurdles,” said the researchers.

“Our study showed that polymer-based materials, particularly PC, can cut module weight by more than 50% compared to glass while offering impact and fire resistance, improved mechanical stability compared to thin front and backsheets, and design flexibility,” said Marengo. “That said, long-term reliability studies and outdoor testing remain essential to demonstrate the durability of PV modules encapsulated with PC sheets.”

The team will now focus on developing market-ready PC-based lightweight photovoltaic modules using commercially available materials compatible with standard industrial lamination processes.

“We also aim to demonstrate their reliability according to international standards and evaluate their outdoor performance under the hot and humid climate conditions of Saudi Arabia’s west coast,” said Marengo.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.