A research team from China’s Yangzhou University has investigated how four rear treatment techniques can improve passivation performance, contact, and electrical performance in TOPCon solar cells and has found that all treatments have beneficial effects.

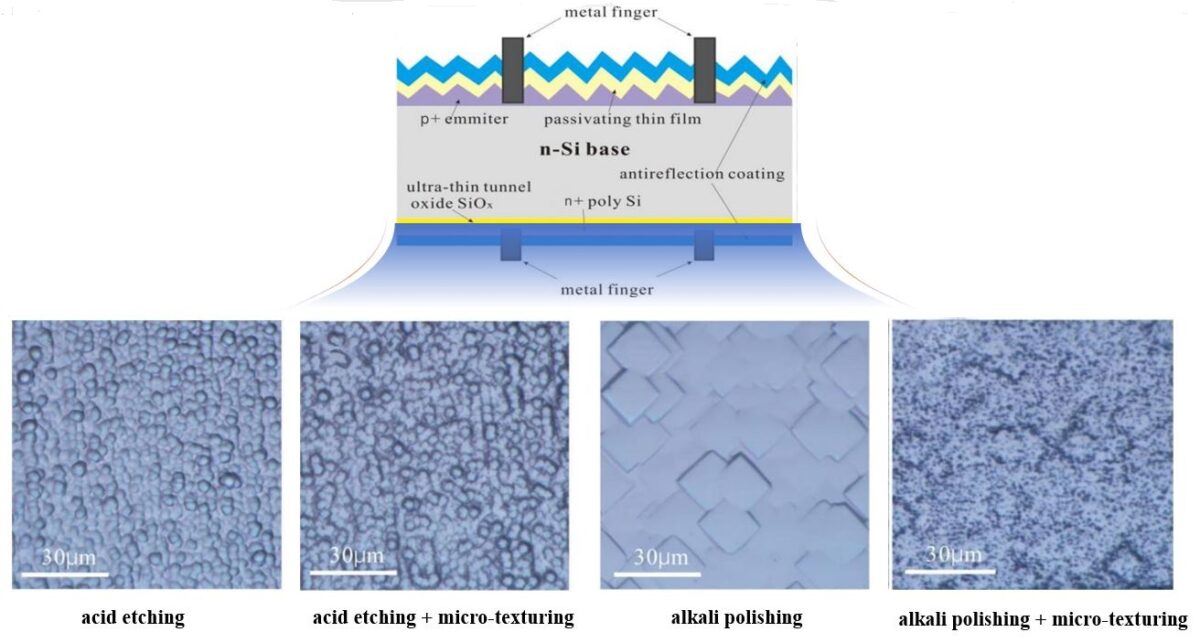

“Our work quantitatively elucidates how micro/nano-rear morphology techniques such as acid etching (E), acid etching with micro-texturing (EM), alkali polishing (P), and alkali polishing with micro-texturing (PM) can co-modulate tunnel-oxide uniformity, contact resistivity, and carrier recombination, offering a direct guideline for n-TOPCon rear design,” the research’s corresponding author, Qinqin Wang, told pv magazine.

The four strategies are intended to minimize the cell’s surface recombination centers and improve light trapping performance.

The scientists noted that rear morphology also has an impact on the TOPCon cell fabrication process, as it requires adjustments to the tunneling oxide thickness, polysilicon thickness, and P-atom doping concentration.

They conducted a series of experiments on TOPCon cells based on Czochralski (Cz) wafers with a size of 182 mm × 182 mm, which underwent conventional alkaline texturing and were treated with boron (B) diffusion. These were then divided into different treatment groups for acid etching or alkali polishing. The passivation layer stack based on aluminum oxide (AlOx) and silicon monoxide (SiOx) was deposited via plasma-enhanced chemical vapor deposition (PECVD).

“The surface morphology and 3D morphology of the rear of the wafers were observed using a scanning electron microscope (SEM, JSM-6510) and an Olympus electron microscope (DSXHRSU),” the scientists explained. “Napson (RG-2000PV) and WEP-Wafer Profile (CVP21) were used to evaluate the sheet resistance of the rear of the wafers and determine the doping profiles.”

The analysis showed that EM treatment is able to increase the cell’s fill factor compared to the simple E treatment, but lowers the open-circuit voltage, which resulted in a cell efficiency of 24.57%. The P2 technique was found to raise both fill factor and open-circuit voltage and to increase the cell efficiency by 0.18% compared to a device that underwent the E treatment, with the device’s efficiency being 24.73%.

Furthermore, the analysis showed that the TOPCon cell with the highest efficiency of 24.78% was the one treated with PM, which pushed the fill factor to 84.24% while maintaining high open-circuit voltage levels.

“The rough surface of the PM treatment allows longer wavelengths of light to penetrate the heavily doped poly-Si, which enhances free carrier absorption and improves light utilization,” the scientists emphasized. “This treatment shows significant advantages in improving the open-circuit voltage and short-circuit current of solar cells. Meanwhile, the rear micro-texturing morphology significantly reduces the contact resistance of the rear, which is conducive to improving the fill factor.”

Their findings can be found in the study “Research on electrical properties and mechanism of n-TOPCon solar cells with different rear surface morphologies,” published in Solar Energy. The research group comprised academics from China’s Changzhou University.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.