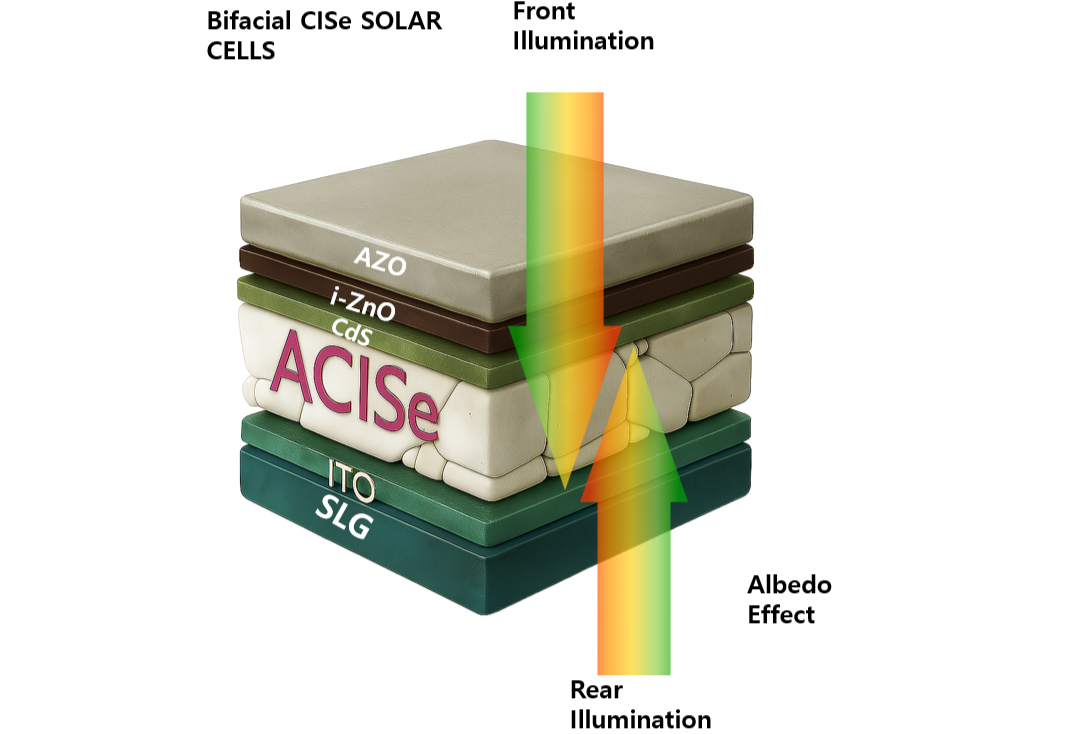

Researchers from Daegu Gyeongbuk Institute of Science and Technology (DGIST) in South Korea announced a new process to make bifacial narrow band copper, indium, selenium (CuInSe₂) solar cells. A transparent conducting oxide (TCO) was used to enable bifacial operation in a lower temperature process that included a silver (Ag) alloy step.

The researchers chose to investigate copper-indium-gallium-selenide (CIGS) materials, and CuInSe₂ (CIS) for bifacial solar cells, in particular, due to their narrow bandgap and potential for use in all-thin-film tandem perovskite solar cells, building-integrated photovoltaics (BIPV), and agrivoltaics.

“In the realm of CIGS materials, CIS is particularly noteworthy. With a bandgap of about 1.0 eV, it’s a promising partner for a tandem solar cell with perovskite. This setup allows for a reduction in the bromine (Br) content in the perovskite layer, making CIS a valuable area for further investigation,” Dae-Hwan Kim, the research’s corresponding author, told pv magazine.

“Our approach was novel in several key aspects. We successfully minimized the use of silver by employing a thin 5 nm Ag layer, which not only maintained high device performance but also improved material cost efficiency,” said Kim.

“Additionally, we optimized a low-temperature growth process that proved highly beneficial for the ITO/CIGS interface,” he went on to say, explaining that at reduced temperatures, the formation of “detrimental” amorphous gallium oxide (GaOx) at the rear interface was “significantly suppressed.”

“As a result, we were able to achieve exceptionally high-power output in the ~1.0 eV CIS category when measured under both rear and bifacial illumination,” Kim specified.

Indeed, the work resulted in a champion cell with a rear-side efficiency of 8.44% and 15.30% on the front.

In the study, samples were fabricated with a 200 nm ITO layer on soda-lime glass, followed by a 5 nm silver (Ag) layer, then the low gallium-doped CIS absorber. A modified multi-stage co-evaporation process was employed to optimize the back interface of the absorber, which was confirmed by cross-sectional field emission scanning electron microscopy imaging.

The group optimized the low-temperature growth process, analyzing the quality of samples processed at 460, 420, and 390 C, both with and without the silver alloy.

It said the champion narrow bandgap CIS with Ag-alloyed devices on the rear side achieved 8.44% efficiency, with the front side registering 15.30%. The bifacial power generation density (BPGD) was 23.1 mW/cm², according to the research. The group claimed these are record results.

Kim added that because the team was able to fabricate bifacial CIS without “significant difficulty,” the process and methodologies from the research could likely be applied in the broader field of bifacial CIGS studies.

The group concluded that the lower deposition temperatures enhanced the rear-side performance, and that the study demonstrated the role of low-temperature processing, low Ga doping, and Ag alloying in suppressing carrier recombination losses in CIS solar cells.

The work is detailed in “Highly Efficient Bifacial Narrow Bandgap Ag-CuInSe2 Solar Cells on ITO,” which appears in Advanced Energy Materials.

The group’s next research focus is to use the high-efficiency narrow bandgap CIS solar cells in bifacial perovskite-CIS tandem architectures. “By leveraging the optimized low-temperature process and rear-side enhancements, we aim to push the performance limits of bifacial tandem devices. In parallel, we are also applying these findings to antimony-based thin-film solar cells within our group, exploring their potential for scalable and efficient photovoltaic applications,” said Kim.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.