From pv magazine Global

Researchers from Spain’s University of Jaen have developed a novel technology for wastewater disinfection and the production of PV energy.

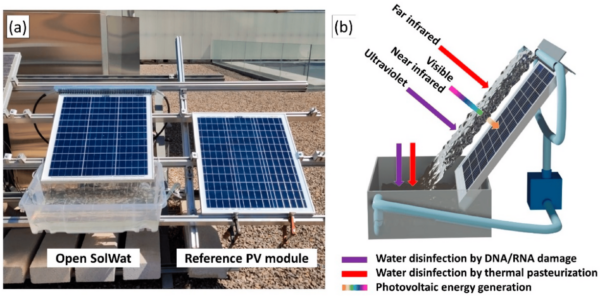

The Open SoWat system is designed for tertiary treatment – the third and final process in wastewater treatment plants (WWTP). It is an upgrade of SolWat technology, which consists of a photochemical technology integrating PV modules and water disinfection reactors.

“To extend the system to commercial use, preliminary experimental studies need to be carried out using a large-scale prototype. Optimization of this technology will involve the use of energy-efficient water pumps. In addition, a study of their energy consumption and an economic analysis of the system will be carried out,” researcher J. Torres told pv magazine.

“The tank is exposed to solar radiation and functions as a solar water disinfection reactor,” the scientists said, noting that in the classic SolWat closed configuration, an 18 mm thin film of wastewater is applied to the PV module, enclosed with borosilicate glass.

To test the feasibility of the system, the scientists have built two prototypes – the Small Open SolWat system and the large Open SolWat system.

“The first reactor consisted only of an L-shaped aluminum profile on top of the PV module, which was equipped with a perforated tube with 53 microtubes for the water outlet, spaced 1 cm apart,” they explained. “The second reactor was an open, translucent water tank measuring 62 cm x 45 cm x 18 cm.”

The largest prototype uses a 45 W module from UK manufacturer PV Logic, two water reactors and a magnetic coupling water pump with an average flow rate of 8.9 L/m manufactured by Germany’s Flojet Corporation. The smaller system uses a module with a nominal power of 5 W.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.