The system utilizes attachable solar collectors (ASCs) that are designed to be combined with PV panels, with the latter being turned into PVT modules on-site without their dismantling.

“Our PVT-ASC system is economically advantageous for small-scale buildings and those with PV panels already installed,” the research’s lead author, Sangmu Bae, told pv magazine. “The ASC is lightweight and designed with a focus on on-site construction. An installer can directly transport two or more ASCs.”

According to Bae, the PVT-ASC system can overcome the technical and economic limitations of existing commercial PVT arrays, which require higher upfront costs compared to conventional PV systems. “Moreover, the PVT-ACS is environmentally beneficial because the work process can be significantly reduced,” he also said. “If PV panels are already installed on a building, disassembly and transportation work can be skipped.”

The researchers said that the type of ASC used for the solution consists of a 1,800 mm × 910 mm rectangular body case, a 1,624 mm × 855 mm closed-loop heat exchanger inserted inside the body case. The collector must be attached to the rear side of the PV panel using thermal grease and carbon steel pipes. “This simple manufacturing process can be applied to buildings without specialized construction skills,” they added.

The solution also includes a waterproof sheet applied to the parts of the ASC that are exposed to the outdoor environment, as well as the inlet and outlet connections of the heat exchanger, which the academics said facilitates workability during the on-site installation.

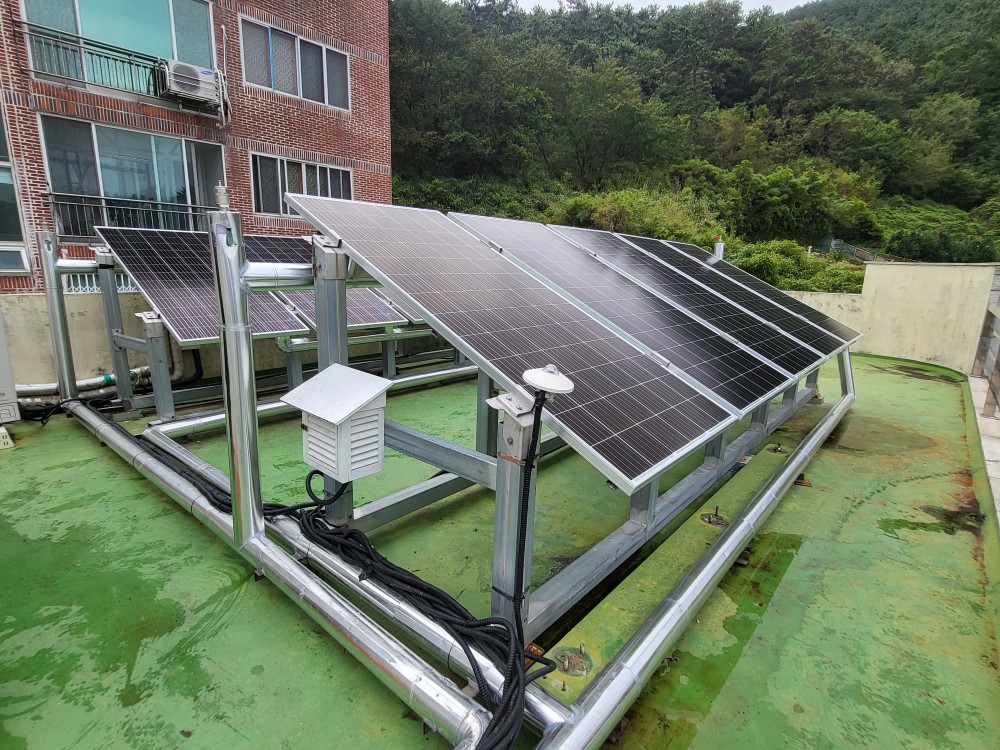

They verified the proposed system configuration in a south-oriented pilot array located in Gimhae-si, South Korea. The system comprises the PVT–ASC panels, a heat storage tank, a circulating pump, thermocouples, a flow meter, a pyranometer, and a data logger.

The measurements showed that the array has a thermal efficiency that is in line with that of commercial PVT products. “The thermal efficiency of the PVT–ASC was reasonable, considering the more straightforward attachment method compared to the roll-bond and lamination methods of typical PVT modules,” the academics explained.

They also conducted an economic analysis showing that the average standard price of the proposed system may be $280/m2, which would be 30%, or $120/m2, lower compared to the standard price of PVT in Korea. They also explained that the total costs of the PVT–ASC system include the disassembly, manufacturing, transportation, and installation work that was saved compared to conventional PVT systems. This sum was estimated at $3,820.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.