From pv magazine Germany

The IAF has developed special power electronics for electrocaloric heat pumps to considerably raise their electrical efficiency.

With the electrocaloric effect, electrical voltage is applied to an electrocaloric material made of special ceramics or polymers, and the material heats up. As soon as the stress is removed, the material cools again, with the entire process being almost completely reversible.

The IAF scientists claimed to have created an ultra-efficient circuit topology for voltage converters with an electrical efficiency of 99.74%. Today’s heat pumps are limited to about 50% of the physical Carnot limit due to technology, but the electrocaloric heat pump could theoretically reach 85%.

These solid-fuel heat pumps are to be brought to market as an alternative to those based on the prevailing compressor technology, as they promise greater efficiency and do not require refrigerants.

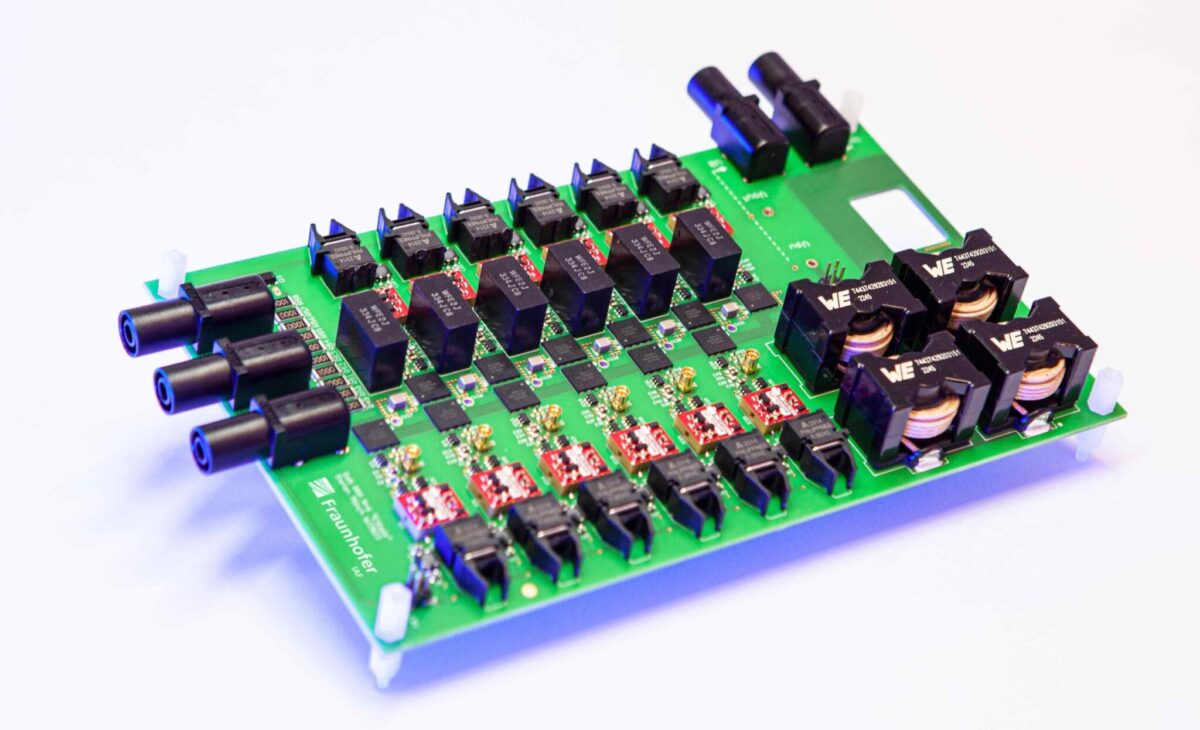

The scientists are now researching components based on the semiconductor gallium nitride (GaN) for higher power density and efficiency. They have succeeded in developing an ultra-efficient circuit topology for voltage converters based on GaN transistors, with an electrical efficiency of 99.74%. The GaN-based multilevel DC/DC converter far surpasses the current state of research of less than 90% recharging efficiency for the electrical control of these new heat pumps.

The increase in the efficiency of the power electronics also has a direct impact on the performance of the entire system, directly leading to a higher coefficient of performance for the entire heat pump system. However, there is still a great deal of research to be done in order to make solid-fuel heat pumps a more efficient and completely emission-free solution for heating and cooling.

“Essential for the realization of a high coefficient of performance of electrocaloric heat pumps is a very high efficiency in the materials, the electronics and the heat transfer,” said Kilian Bartholomé, manager of the ElKaWe project. “If you get all this under control, electrocaloric technology has enormous potential.”

Six Fraunhofer institutes were involved in the ElKaWe project. They have published their results in the IEEE Journal of Emerging and Selected Topics in Power Electronics.

*The headline of the article was amended on July 24 to reflect that device efficiency is 99.74% and not 97.4%, as we previously wrote.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.