Solar PV panels are a PV plant’s major components and are intended to perform for 25 years. Therefore, testing PV panels is essential to ensure their reliability and safety. Conformity assessment bodies and calibration laboratories play a vital role in ensuring the quality of solar PV panels in factories or solar PV plants.

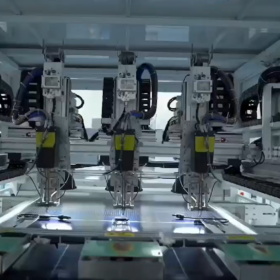

Sun simulator is considered the heart of a testing or calibration lab used to test solar PV panels indoors under controlled and repeatable conditions. It uses an electrically powered lamp to simulate sunlight over a focal plane providing uniformity, collimation, and light spectrum matching daylight.

Special attention is needed while procuring a flasher/sun simulator for a lab as measurement uncertainty of testing/calibration depends on the accuracy of the flasher. Various parameters should be considered for the selection of a flasher.

Size of the PV module

The module sizes have been increasing for the last few years. With M10 and M12 wafers, the maximum size of the module has reached up to 2,465 mm x 1,134 mm and 2,384×1,103 mm. In most Indian solar PV labs, very large-size modules can’t be tested as the module test area of the flasher is shorter than the module size.

Pulse length

Nowadays, high-efficiency PERC modules have replaced BSF modules in the PV module market. In the coming days, high-efficiency modules like TOPCon and HJT will capture the module market.

For characterizing BSF panels, 10 ms pulse is required. On the other hand, pulse width of 60 ms is required for PERC, 100 ms for TOPCon, and >200ms for HJT modules. Also, the flasher should come with a really long pulse. Otherwise, measurement uncertainty will be higher.

Simulator classification

IEC 60904-9 specifies the requirements of a sun simulator. The spectral mismatch, spatial non-uniformity of irradiance, and temporal instability of irradiance are the significant parameters based on which the Sun simulator is classified as A+A+A+, AAA, BBA, etc. One should verify whether the particular flasher is providing a full spectrum of 300 nm to 1200 nm or not. This is nowadays measured by the % spectral coverage (SPC) according to IEC 60903-9 ed3.

Irradiance range

Irradiance range is another crucial parameter to be kept in mind while selecting a flasher. We need an irradiance range from 100W/m² to 1100W/m² for testing as per IEC 61853-1 standard. For bifacial module testing, 1300W/m² irradiance is required. So, ideally, go for a flasher capable of providing irradiance range from 100 W/m² to 1,300 W/m².

For solar PV, quality infrastructure services are essential throughout the value chain, from components manufacturing to electricity consumption. Only with the necessary quality infrastructure services in place can it be guaranteed that the technology and installation have the required quality level so that the expected amount of energy can be safely produced and consumed. Testing and certification labs play a significant role in the quality assurance of solar panels. So, these labs should be equipped with the best equipment to check the quality of imported or indigenous solar PV panels.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.