From pv magazine 10/2021

What are the drivers behind First Solar’s decision to invest in India?

First of all, the Indian government is incentivizing backward integration. It’s trying to look at how you create more value in India, as opposed to just doing [module] assembly.

Coupled with this is the fact that over the last two years, the cost of logistics has become a significant portion of the overall cost of modules. Container pricing has gone up three to four times since the Covid-19 outbreak and now that logistics cost is pinching either the supplier or the buyer, depending on who takes the cost. Also, there’s the risk of tariff actions and trade barriers as well.

So, strategically, as a company, we have decided to expand our global footprint and manufacture close to our markets where we have major demand. Outside of the U.S., India is one of the biggest market opportunities.

There’s no question that India’s demand for photovoltaics is going to be robust over the next decade, given the overarching policy initiatives plus the focus on self-reliance. By setting up our facility in India, we de-risk ourselves from the exposure to vagaries of the logistics cost and disruption, as well as any future trade and tariff action.

First Solar modules in India have been competing with module imports from China. But now that a lot of Indian manufacturers have also announced plans for vertically integrated fabs, how do you see the competitive landscape?

Thin-film production has always had a lower capital outlay per watt compared to crystalline silicon, because of the simplicity of the process. It’s essentially a low-energy, low-water-intensity manufacturing process with very little wastage of material. If you look at crystalline silicon, a lot of cutting and wastage goes on, with the process involving different manufacturers, different permutations and combinations, and so on.

The second thing is that in the crystalline silicon industry, you could decide what stage of integration you want, but the less you integrate, the more is your bill-of-material cost. You [need to] factor in all of that and compare with First Solar’s fully integrated process.

For us, the biggest bill-of-material component is the float glass, something which is available in India. It’s easier to localize. Then you have the frame, the packaging, all of which we can and will start developing to build the local supply chain in India. So as we start production in two years, right out of the gate we would be looking at about 60% local value addition. And that will keep going higher and higher.

What gives you confidence in the Indian solar market from the viewpoint of consumer adoption?

India is a high-temperature, high-humidity market. Our modules produce more energy for the same installed capacity because of a superior temperature coefficient and spectral correction factor. Depending on the project location, there could be anywhere from 5% to 8% more energy generation over a 25-year life cycle.

Moreover, First Solar is a highly bankable brand with a strong operating history over the last 10 years. We were the second company in India to hit the 1 GW module installation milestone, but since 2017 we’ve had capacity constraints. Globally, a lot of our capacity was allocated to other markets. Therefore, as a company, we’ve decided to expand our global footprint in markets [like India] where our technology has been successfully installed and is liked by customers.

Does First Solar intend to export PV modules to other markets from its proposed India plant?

Mostly it’s going to be local. This is an “in India, for India” production. As you know, we have other manufacturing plants and other manufacturing sites in the region. We’ve got plants in Malaysia and Vietnam, each of which is producing about 3 GW today. And of, course, we have the U.S. expansion, with which we would reach about 6.5 GW in the US. International demand will mostly be met by our Malaysian and Vietnamese plants, while the Indian plant will service the domestic market with approximately 90 to 95% of its capacity.

What technological advancements could be expected in the modules produced out of the India facility?

We announced a 3.3 GW expansion at the Ohio facility in the U.S. And then two months later we announced a similar 3.3 GW expansion in India. So the U.S. facility and the Indian facility are mirror images of each other. They’re going to have the same process equipment and the same product. What we will produce in both the U.S. and the India factories is going to be our next generation module.

Currently, we are producing Series 6 modules. The new modules will have a large-format, the same technology in terms of the semiconductor material, and the characteristics of the semiconducter will be identical to the Series 6 CuRE product that we are starting to produce in our existing facilities. CuRe technology is extremely beneficial for Indian customers as it’s going to have a very low long-term degradation rate. We are giving it a warranty at 0.2% year-on-year long-term degradation.

Historically, solar panels have had a long-term degradation warranties of about 0.7%. Nowadays most people are offering 0.5%. The CuRe technology takes it to 0.2%, and that would mean more value to our customers, especially those in the utility-scale segment.

What’s your installed base in India?

We have just above 2 GW of the total operating footprint. Most of that was installed before 2017. The global installed base for First Solar is over 30 GW. And some of those installations date way back beyond 25 years.

With First Solar coming to India, can we say that the Indian market is again set for a reversal of trends?

When we had the capacity and we were selling in India between the period of, let’s say, 2011 to 2017, we had about a 15% share of the market in the utility-scale segment, excluding DCR (domestic content requirement) projects. And I think with the upcoming 3 GW capacity, we should get back to that kind of percentage. I think the market is big enough for multiple technologies to coexist. There is no one size that fits all.

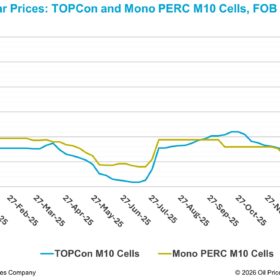

We have our strengths in large utility-scale projects. Likewise, very high-efficiency mono PERC or maybe even heterojunction technologies will have a better return for the investors in rooftop and space-constrained applications. So there are different options available. Each has its strengths, depending on the type of installation, the geography, and the type of offtake. And we think we will be able to carve a share for ourselves, especially considering our operating history in India.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Excellent Coverage. Gives updates on the latest technologies and developments. I always look forward to PV Magazine News Letters and your webinars. Thanks for the wealth of information

What is missing is… what is First Solar’s “end-of- (first)life” recyling Strategy and Commitments…

I wish readers can be given more info. on this aspect for ALL PV Panel Manufacturers.