India’s Ministry of New and Renewable Energy (MNRE) has announced a new target to generate 450 GW of electricity from renewable energy sources by the year 2030, with about 300 GW coming from solar photovoltaic (PV). Earlier, 100 GW solar PV installations were planned under the target of 175 GW of renewable energy sources by the year 2022.

Considering further growth in the future, India needs quality infrastructure in place for the solar photovoltaic system and related solar PV waste management at the earliest. The solar module waste is estimated to grow to 1.8 million tonnes annually by the year 2050 in India.

MNRE is the regulatory body for the policy framework related to new and renewable energy sources, including the solar photovoltaic. Gurugram-based National Institute of Solar Energy (NISE), an autonomous institution of MNRE, provides testing, certification and standardization, monitoring, and evaluation by NABL (National Accreditation Board for Testing and Calibration Laboratories) accredited solar photovoltaic module testing laboratory. New Delhi-based Solar Energy Corporation of India Limited (SECI) is another institution of MNRE under public-sector undertaking that primarily facilitates the implementation of the National Solar Mission of India to achieve the target set therein.

As per new guidelines of MNRE, testing laboratories must be accredited by both NABL and BIS (Bureau of Indian Standards). This requirement is fulfilled by only a few laboratories like NISE, Gurugram; TUV Rheinland (India), Bengaluru; UL, Bengaluru; Electrical Research & Development Association (ERDA), Gujrat; HiPhysix, Pune; Electronics Test Laboratory (ERTL), Kolkata; and Electronics Test and Development Centre (ETDC), Bengaluru.

PV module design and performance evaluation test should be as per the international standards (IEC 61215 /IEC 61646 and IEC 61730-1 & 2) or equivalent Indian standards (IS 14286/16077/61730).

Testing capacities of all these centers may not be sufficient to fulfill the Indian market needs, given the expected growth of PV installations by 2030 and perhaps beyond. Usually, the requisite number of solar panel production batches should be tested to ensure quality. The situation calls for the strengthening of the capacity of accredited testing and calibration facilities in the country.

Mentioning the traceability chain involved in the measurement should also be made mandatory on all test certificates.

CSIR-NPL (Council of Scientific and Industrial Research – National Physical Laboratory), being National Measurement Institute (NMI) of India, maintains all primary standards for SI units and establishes the primary criterion for solar cell calibration with financial support from MNRE.

Usually, solar modules are provided with a 25-year linear performance guarantee for their output peak watt capacity, which should not be less than 80% at the end of 25 years. This means a degradation rate of < 0.8% per year. In some instances, the stability may reach close to 50 years with 90-95% of peak power, meaning a degradation rate of just < 0.4% per year.

However, a study done by NISE in collaboration with the Indian Institute of Technology (IIT) Bombay on PV module degradation observed an alarmingly high degradation rate of 2-5%. This means the life of these panels will be reduced by 40-50%, and the panels would last for 10-12 years only.

As these installed panels may not complete their projected life of 20-25 years, there may be adverse financial implications with huge revenue loss. This may also create early-loss PV waste.

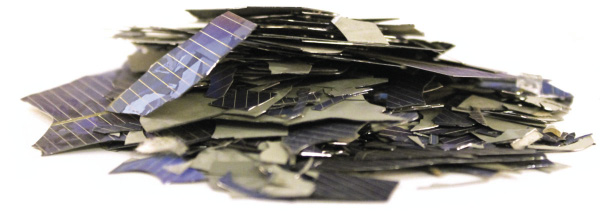

The majority of these solar PV installations employed cost-effective imported panels, perhaps at the cost of quality. There is a need to adopt a proper way to dispose of these panels at the end of their life to avoid a harmful impact on the environment.

The fundamental reason behind the fast degradation of PV modules may be a lack of quality check of the imported cells and modules in the country of their origin and perhaps an absence of the revalidation mechanism at Indian test centers. Usually, PV modules are tested as per the conditions suiting the western part of the globe. Non-traceability of testing and calibration parameters/equipment as per Indian environmental conditions is also a major hindrance in ensuring quality checks.

Moreover, photovoltaic panels are not so green if not suitably handled in an environment-friendly manner after their end of life. Disposal of scrapped PV systems will become a major problem in coming years, given progressing huge installations in India.

The situation calls for establishing an infrastructure for environment-friendly recovery of valuable materials from scrapped photovoltaic modules. Constant R&D efforts are required towards exploring efficient and cost-effective processes for the recovery of useful materials from used solar modules. India lacks a large-scale workable solution to this upcoming problem. Innovating efficient, cost-effective, and environment-friendly processes for recycling and reusing PV system materials is a key challenge before researchers and needs to be looked upon as a social responsibility by all stakeholders.

Research institutes and companies in various countries are working on developing efficient recycling processes for PV modules. A French company called Velia is working on a mega project to develop a unique and efficient method for solar module recycling.

Back home, SOFIES India and Poseidon Solar are working on solar waste projects in India. CSIR-NPL has also recently initiated the work on recycling silicon solar waste. Based on its ongoing efforts, it is looking to create a quality procedure report for solar system recycling.

The European Union (EU) has included PV components under electronic devices in the waste electrical and electronic equipment (WEEE) directive in the year 2012 and set an international benchmark in waste management rule. Other countries are also coming out with some solar PV waste management rules.

However, India doesn’t have any clear-cut policy on dealing with solar PV waste. Though there is a mention of solar waste recycling in the India Solar Mission Program, it lacks clear-cut policy and rules to be followed.

The Union Ministry of Environment, Forest and Climate Change (MoEF&CC) is the authority for policy-making of waste management in India. It has notified the new Solid Waste Management Rules 2018, encompassing plastic waste, electronic waste, biomedical waste, and construction and demolition waste, but there is no mention of solar waste. This rule has an important clause like Producer Responsibility Organization (PRO) registration and electronic waste collection targets for all the producers, which should also be applied to solar industries.

As PV waste is set to rise rapidly in the coming decades, India needs to invest in efficient recycling technologies and devise a clear-cut policy for the safe disposal of PV waste. Guidelines for stringent quality checks and validation for both imported and locally produced solar panels are also needed to avoid early-loss solar waste. There is also a need to create awareness about the safe disposal of solar waste.

The author is grateful to Director, CSIR National Physical Laboratory, New Delhi (India), for his support. He is also thankful to all past and present group members of Photovoltaic Metrology Group, CSIR-NPL, for their help.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.