From pv magazine International

Scientists at the Central University of Jharkhand, in India, have simulated a methylammonium tin iodide perovskite solar cell optimized with a hole transport layer (HTL) made of copper (I) oxide (Cu2O) and an electron transport layer (ETL) based on titanium oxide (TiO2).

“We are now planning to fabricate the device in a laboratory,” research co-author Basudev Pradhan, told pv magazine. “The estimated cost of this type of perovskite-based solar panel could be 8-10 times cheaper, over the present silicon-based solar panels.” According to him, this type of solar cell can be easily manufactured by using roll-to-roll screen printing machines.

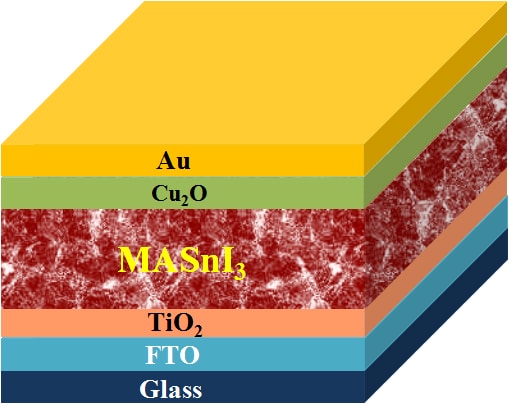

The lead-free perovskite solar cell has an n–i–p layout and is composed of a fluorine-doped tin oxide (FTO) substrate, a TiO2 layer, a methylammonium tin iodide (MASnI3) perovskite film, a Cu2O hole transport layer (HTL), and a layer made of gold (Au).

The numerical simulations were made through the SCAPS-1D tool for thin-film solar cells developed at the Department of Electronics and Information Systems (ELIS) of the University of Ghent, in Belgium.

The academics explained that the optimization of the ETL is key to achieving high efficiencies and they found that a thickness in the range of 40-60 nm, which is nearly equal to carrier diffusion length, is ideal. The diffusion length is the average distance that the excess carriers can cover before they recombine.

“We have optimized different properties like doping density [and] the thickness of active materials as well as [the] hole and electron transport layer (HTL and ETL) for the further improvement of … device performance,” the researchers said. “Moreover, it has been observed that the varying HTL thickness has minimal impact on the device operation and its performance, whereas the thicknesses of [the] ETL and absorber layers significantly impact the device parameters.”

The simulations showed, the scientists went on to say, that the proposed cell configuration has the potential to reach a power conversion efficiency of 27.43%, a short circuit current density of 25.97 mA/cm2, an open-circuit voltage of 1.203 V, and a fill factor of 87.79%.

The device is described in the paper Performance optimization of lead free-MASnI3 based solar cell with 27% efficiency by numerical simulation, published in Optical Materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.