From pv magazine 12/2020

Some things change while others remain the same. There is a clear sense that the rate of technology change within the PV industry is accelerating. However, some technologies and process steps have proven to be durable, despite much changing around them.

This is particularly true of flatbed screen-printed solar cell metallization. The approach has been used in PV and in some applications in electronics production. It has remain largely unchanged since the 1970s, although material development has delivered significant gains. In the near future, more fundamental changes to the printing process could take place with a technology project led by Fraunhofer ISE pointing toward a future in which cell metallization can be carried out at twice the throughput that can currently be achieved.

“Printing is something that does seem to be stubbornly resistant to change,” explains Alex Barrows, the director of research at PV production consultancy Exawatt. “There always seems to be lots of interesting ideas, but they don’t seem to go anywhere.”

Work to replace cell screen printing began roughly a decade ago, at the German PV research center, starting with a feasibility study into alternative printing processes. And on the basis of promising results, the last decade saw the Rock-Star and now Rock-It projects born, which look to introduce both rotary and flexographic printing to PV cells.

New methods

The perseverance of screen printing, where a squeegee presses silver paste through a fine screen and onto the PV cell, is perhaps related to its simplicity. It is able to deliver ever finer lines and can handle a range of highly optimized pastes. For the stable of standard and high-efficiency cell architectures, screen printing has been able to meet the needs of PV manufacturers while continuing to achieve cost reductions on the back of finer and optimally shaped conductive lines.

Yet the metallization station has also been somewhat limited in terms of increased throughput, and it appears to have hit a ceiling of 4,000 cells per hour. General process requirements like the necessity of a flooding and printing step make it challenging to further reduce the cycle time of the flatbed screen printing process substantially, according to Andreas Lorenz, head of the printing technology group at Fraunhofer ISE. Lorenz evaluated the applicability of rotary printing methods within his PhD thesis.

“Rotary printing methods offer the great benefit of a continuous metallization process which has the potential to significantly reduce the effective cycle time per cell. Rotary printing has the potential to increase the printing velocity even further and thus enable a real ‘revolution’ with respect to throughput – if sufficient solutions for the precise transport of the silicon wafers can be developed,” Lorenz says.

Enter: Rock-Star

To achieve the step change required to de-bottleneck the process, the Fraunhofer team – alongside industry partners including Asys, Gallus Ferd. Rüesch, and ContiTech Elastomer Coatings – developed the production equipment and printing componentry to be able to apply rotary and flexographic printing to solar cells.

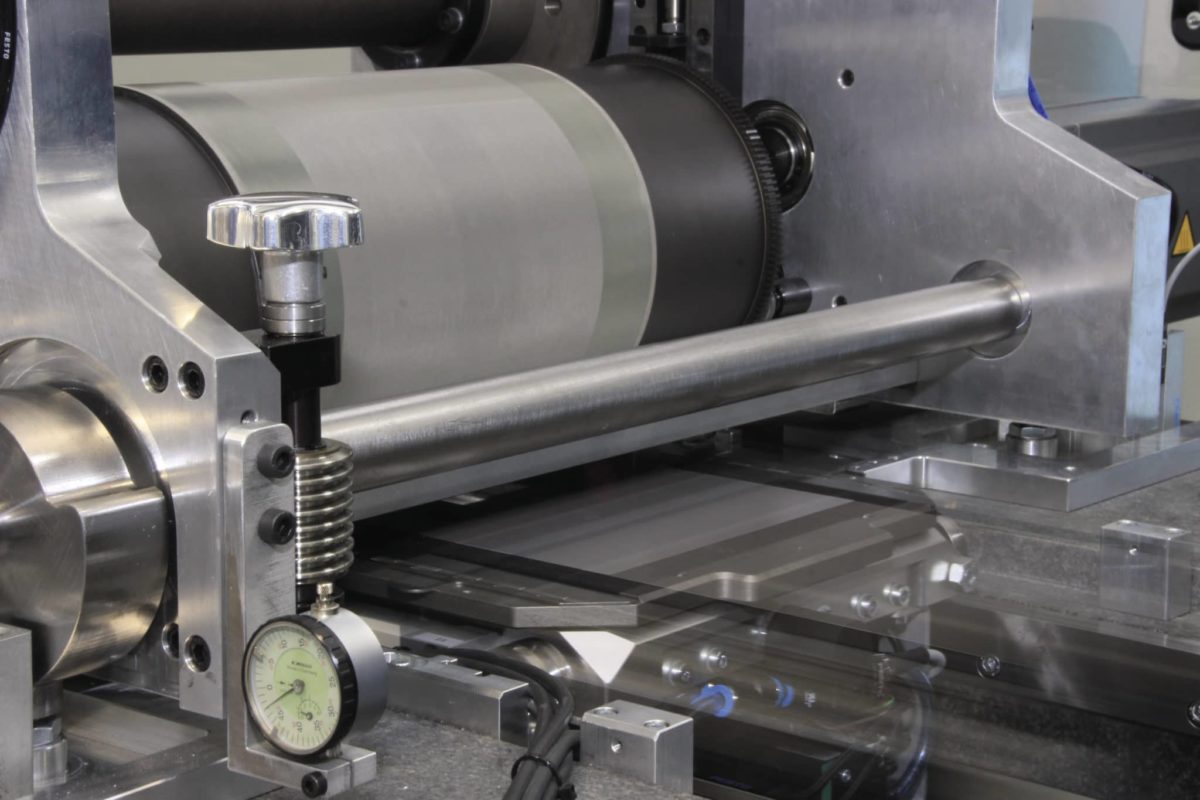

The rotary process in particular, notes Lorenz, represents “really a revolutionary approach” to the PV cell metallization process. The reason being the combination of a shuttle-based transport with the continous rotary printing process – allowing the cells to pass continuously beneath the cylindrical printing form. The silver paste, slightly modified commercial flatbed screen printing paste, is pressed through a rotating cylinder screen. Gallus Ferd supplied the Gallus Screeny P-Line cylinder screens for the Rock-Star process.

The Rock-Star tool was unveiled at an online event in July. It can achieve a throughput of up to 8,000 wafers an hour in an inline configuration. Both front and rear metallization on P-type PERC cells has been carried out and while the rear side metallization is of the same quality as flatbed printing on the new tool, the optimization of an ultra-fine line front side metallization is still in development. At present, the rotary process can achieve line thicknesses of 40 microns but requires more work to achieve finer lines through further collaboration with paste suppliers.

“In the current state, the machine is able to print with a speed which enables a dual line of the throughput of modern flatbed screen printing lines,” says Lorenz. “We are still testing. It is definitely ambitious to realize such a printing velocity in a production environment and we see the necessity to implement adequate solutions for wafer handling and process control.”

Rock-Star equipment partner Asys designed and built the demonstration tool. It is equipped with the capability to install both a rotary and flexographic printing process, along with different camera technologies for precise alignment.

“It is an R&D tool … but the interest from the industrial customers is pretty high,” says Matthias Drews, Asys’ director of solar sales. He reports that when the tool was unveiled, more than 50 industry participants were attracted to the virtual unveiling.

Drews says that at present, the rotary process is particularly well suited to rear-side metallization. However, ongoing refinement could see it applied more effectively to the front side.

“The next step will be the inspection tools and the other things around metallization: a fast drying process, much faster than we can at the moment, IV test, print inspection, and later on color inspection,” says Drews. “All of these things will come up step-by-step over time. When all of these steps are done, on one lane we’ll be able to achieve 8,000 wafers per hour.”

Market impact

Drews acknowledges that the R&D tool at present is not cheap, but that with maturity costs will come down. And with the incremental cost-down imperative of PV cell manufacturing, a halving of process times, from 1 second to 0.5 seconds, will likely be attractive to manufacturers.

“Compared to what we’ve seen other manufacturers using, it probably does about double throughput as they claim,” observes Exawatt’s Barrows. “Filings from Longi and Jolywood in 2019 indicate that the machines they were using achieve 3,500 cells per hour, which indicates you can potentially get a significant throughput boost. If the tool comes in at the same price and throughput then you could believe it could work.”

Barrows describes the cell production process as being one in which “a lot of small cost reductions can begin to add up,” indicating that the Rock-Star process could be effective. However, he cautions that unexpected downtimes from the new process could undermine its application. “There is less wiggle room with risks,” says Barrows. “You don’t have to have much downturn on a [cell] line to wipe out any saving.”

The follow-up project to Rock-Star, Rock-It, is currently underway and is funded by the German Federal Ministry of Education and Research (BMBF) under its “R&D for Photovoltaics” program. The project will finish in February 2022, after which point, Fraunhofer’s Lorenz says, an industrial implementation of the new solution will very likely be the focus.

The technology is generally not limited to a certain wafer size. Wafer formats up to M12 can be processed on a modified production platform.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.