From pv magazine International

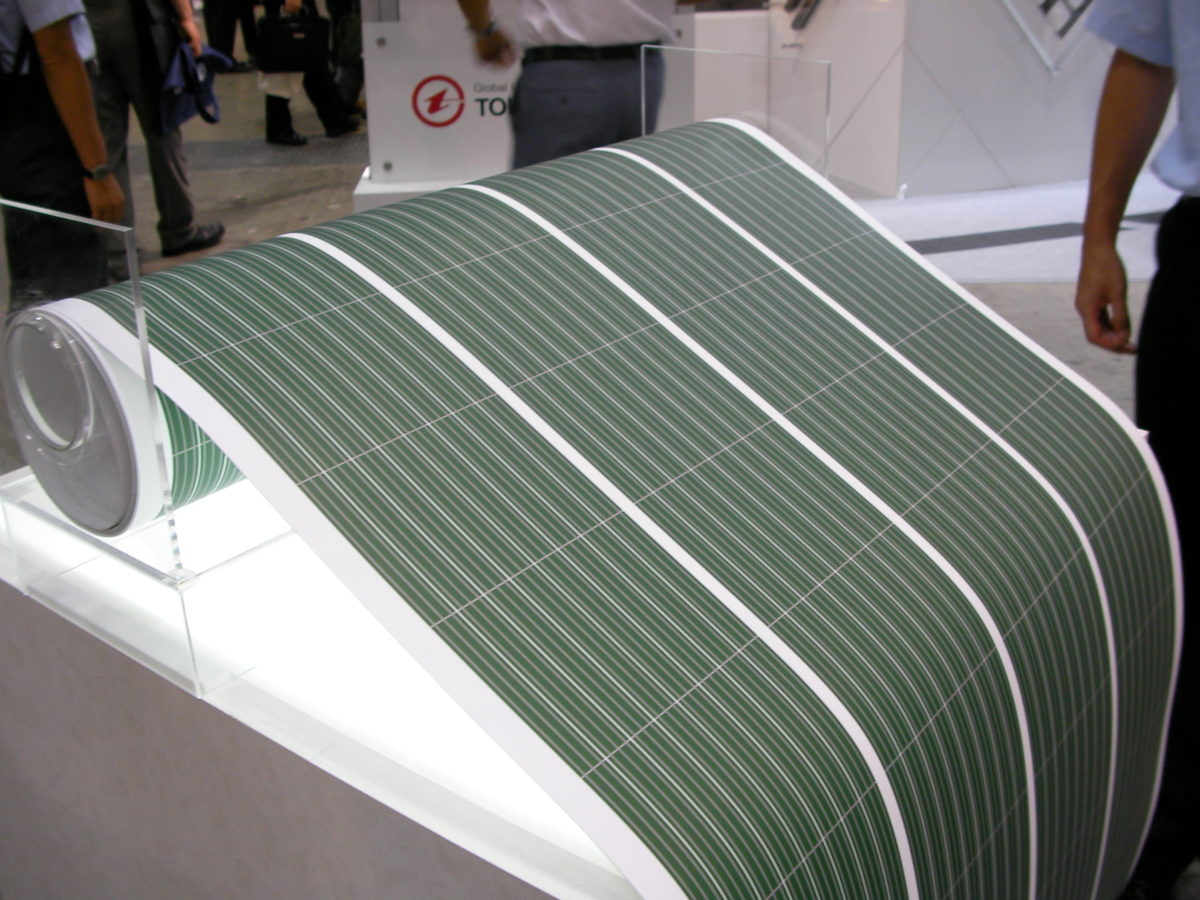

An international research team from the University of Oxford in the United Kingdom and the Dresden University of Technology in Germany has investigated possible current and future applications for organic solar technologies and has concluded that organic PV devices may leave the enclosure of the BIPV and portable electronics business and also be adopted for power generation in the electricity market, if higher efficiency and lower costs will be achieved.

In the paper Organic Solar Cells—The Path to Commercial Success, published in Advanced Energy Materials, the British-German group note that in terms of short circuit current and fill factor, organic cells are already able to compete with their crystalline silicon or thin-film counterparts, and that is currently limiting their industrial development is low open‐circuit voltage.

Efficiency and stability issues

According to the scientists, the best way to reduce open‐circuit voltage losses in these devices and reduce the gap between them and other PV technologies is by reducing non-radiative losses. These voltage losses are mostly due to the recombination of photo-generated charge carriers, including inevitable radiative recombination, and only partially due to the necessity of an electron transfer event to dissociate the excitons.

Future research, the academics went on to say, will also have to increase the long-term stability of these cells. They identified the main causes of degradation as the diffusion of molecular oxygen and water into the devices, mechanical failures that can happen in the device stack, and defective module design and encapsulation. “In addition to the materials challenge, patterning the active materials and electrodes in production‐compatible processes to create the subcells and interconnects with little losses is essential,” they further explained.

Polymer cells versus small molecule cells

Two main deposition technologies are currently competing in the market, according to the study, one using polymers, which are long molecular chains, and one utilizing soluble small molecules, also known as oligomers, deposited through slot‐die coating or screen printing. “At first sight, solution processing seems to be preferable because it requires relatively simple techniques and does not need tools whose upfront cost is higher,” the researchers stated. “However, to predict the development for OSC, it is very interesting to look at the commercialization of light-emitting diodes: In this field, small‐molecule devices and polymer devices were discovered almost simultaneously.”

The efficiency of polymer-based cells is still higher than those based on vacuum‐processed small‐molecules as they have better light absorption. “However, recent progress in solution‐processed N-Fluorobenzenesulfonmide (NFA)‐based small molecule cells with efficiency beyond 14% indicates that there is potential for NFA for vacuum‐processed OSC, as well,” the scientist said.

Power PV applications

In the future, 0rganic PV could be applied in the large-scale PV segment, which the scientists called “power” PV applications. “What finally counts in these ‘power’ PV applications is the energy generation cost in cents per kilowatt‐hour,” they specified. “This already removes an often‐used argument in favor of organic solar: ‘if it is cheap enough, efficiency does not matter’.” According to them, in this segment land costs and balance of system costs, in particular, make impossible a market entry for organic PV technologies under current market conditions. “Therefore, organic solar can only compete with crystalline silicon if it reaches module efficiencies around 20%, lifetimes of more than 20 years, and cost well below silicon,” they further explained, adding that increasing the devices’ lifetime is so far the most achievable among the three goals.

The British-German team also highlighted that it is currently difficult to outline a future price trajectory for the organic PV technology, due to the current lack of big production volumes in the industry. “This is not surprising since OSC is a completely new technology and all tools and materials are mass‐produced for the first time,” it affirmed. “In contrast, silicon PV has seen a decades‐long cost scaling history.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.