India has set an ambitious target of reaching 450 GW of renewables capacity by 2030, most of which is expected to come from new solar deployment. The country now has the challenge of meeting its renewables target whilst aligning with Prime Minister Narendra Modi’s goal to build a ‘Self-Reliant India’. This ambition is driving the government’s shift in procurement strategy to restrict imports and encourage domestic manufacturing. Some commentators have observed that going ‘cold turkey’ on imports is the best way to develop indigenous capabilities.

In the wake of the Covid crisis, economies the world over are talking about ‘building back better’ and the ‘green bounce’; essentially, seeing the need to rebuild their economies as an opportunity to develop low-carbon power and zero-emission transport.

As far as renewable energy is concerned, India has a domestic manufacturing capability for wind turbines, but it currently depends on imports for most of its solar equipment. There is an urgent need to grow solar capacity to boost access to clean energy, electrify transport and deliver wider benefits for society.

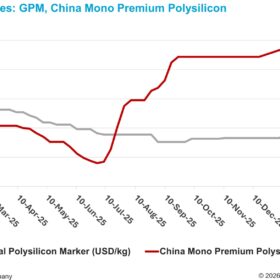

In FY 2019-20, India imported INR 128 billion ($1.7 billion) of solar cells and modules, with nearly 80% coming from China. The question is, with no indigenous solar manufacturing to speak of, and with aspirations to become a giga-scale manufacturing centre, how can the country accelerate from zero to INR 128 billion? Going ‘cold turkey’ is probably not the answer, but manufacturing under license might be.

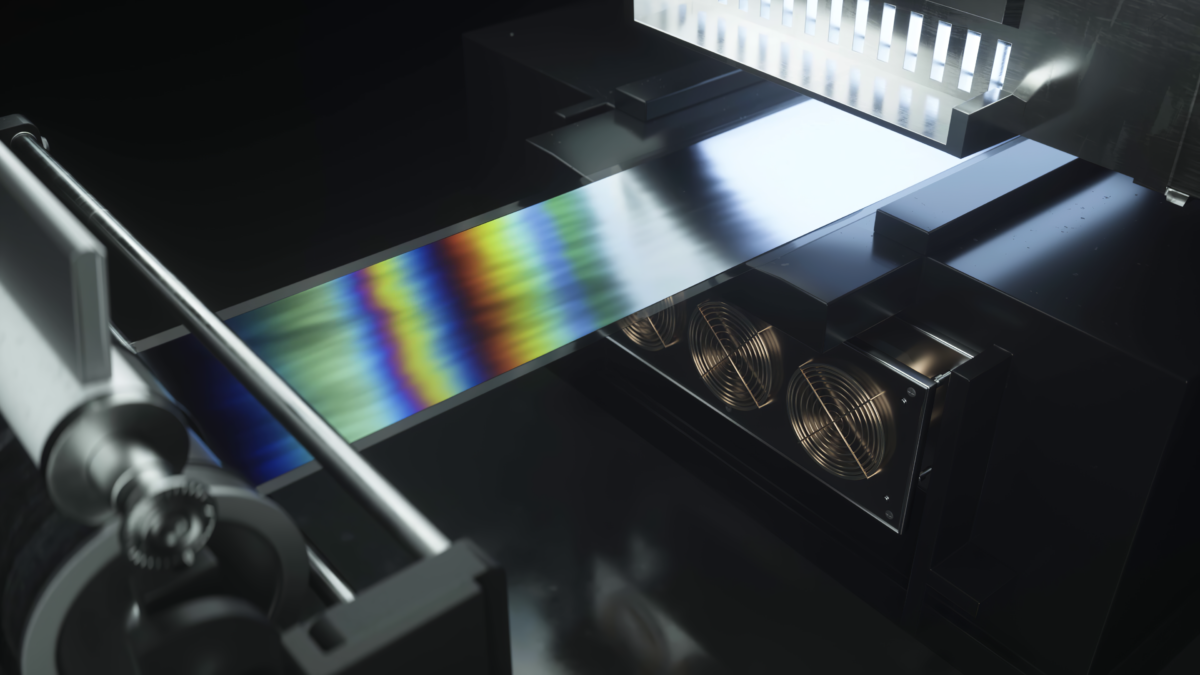

‘Made in India’ is the perfect opportunity to embrace disruptive technology. If the solar PV industry was starting from scratch, we would manufacture solar material that is light enough to be used on fragile, rural rooftops; is cheap enough to displace the use of fossil fuel power generation both on- and off-grid; and can be manufactured at giga-watt scales using simple processes.

Such enabling technologies are on the horizon. UK-based Power Roll is developing just such a flexible, solar film. The company is seeking manufacturing partners to license its intellectual property (IP) to manufacture locally. Power Roll has already established a successful manufacturing joint venture with Deki Electronics. The joint venture, based in Uttar Pradesh, uses Power Roll’s flexible film to make capacitors – electric storage devices that feature in virtually all electrical products.

India’s solar power generation capacity has grown exponentially since 2010, but its success in solar suffers from a major distortion. India has reached 32,176 MW of utility-scale solar plants supplying electricity to the grid, but only 5,740 MW of rooftop solar and 978 MW off-grid solar.

There are many benefits of deploying solar to India’s 600,000 villages. Most power will be consumed where it is generated, which reduces the need for new transmission infrastructure. With agriculture consuming around 18% of India’s electricity generation, an attractive feed-in tariff for decentralised solar power generation in rural India would lead to a surge in private investment and increase farmers’ incomes.

Technologies like Power Roll’s present an opportunity for Indian businesses to take the lead in next-generation solar by manufacturing locally under license. Manufacturing such technology at gigawatt scale would see the price of solar generation drop to $0.03/Watt.

The focus on rural India with such technologies can help India shift to a low-carbon growth trajectory and meet its renewables goals while aligning with its ‘Made in India’ industrial strategy.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I agree…. using the 600,000 Villages, with over 2 Million km2 of Agricultural Land, has to be a major part of the solution for providing Clean Solar Energy, specially if the AgriVoltaics Option is harnessed…. in a “land challenged” country with 16 Times the Population Density of the USA… and twice that of Europe…

Glad to know that use of the widely dispersed and immense farmland in India is under consideration to “Solve” the Supply of Clean Energy/Electricity… so that “unused” land and forests are left “pristine” for future needs.