From pv magazine International

Researchers from the Madurai Kamaraj University in India have claimed pouch lamination – of the sort routinely used to strengthen documents by sealing them in a sturdy plastic covering – could be used to encapsulate solar cells.

The scientists say a solar cell they laminated in such fashion offered better ultraviolet (UV) photon absorption than devices treated with a polymer surface coating.

The research ignored factors such as durability and cost, to focus exclusively on the technical viability of deploying such a rapid, low-cost encapsulant technique for testing at laboratory level. “The ultimate advantage of this technique would be its simplicity compared to traditional lamination, which is tedious and energy consuming,” research co-author Vasu Veerapandy told pv magazine. “It can be performed using a tabletop pouch lamination machine which any laboratory can afford.”

Approach

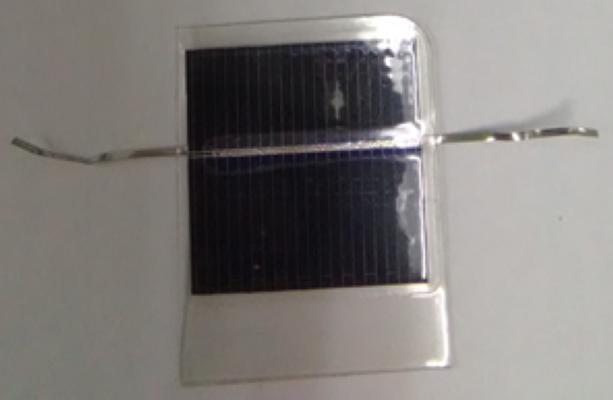

The researchers encapsulated a 3cm2 textured polycrystalline square solar PV wafer using a pouch laminator and compared its performance with that of a device coated with polymethyl methacrylate (PMMA).

“The cell’s diffuse reflectance with the encapsulant exhibits better photon absorption in the UV region, which is verified from improved external quantum efficiency,” the researchers wrote.

The group said, the encapsulated cell lost a small percentage of visible photons but electrical performance was not affected. “On the other hand, the PMMA-coated cells showed an outstanding photon-to-electron conversion but [that] did not result in effective charge collection,” the academics stated.

“We concluded that encapsulation through small scale pouch lamination would be a better passive approach [for] lab scale experimental simulation of module performance [using] a cell, than a polymer surface coating, which affects electrical properties of the solar cells,” said Veerapandy.

Cost

The research co-author said the type of lamination required can be achieved for the price of laminating an identity card. “So it won’t add any prominent cost to the device fabrication,” the academic said. “The percentage of breakage is minimal if the tabbing [is] kept flat, without crumples.”

The researchers suggested the lamination method could reduce the cost of using solar energy to power small scale research work on microbial decontamination, bioinstrumentation and using photometric systems for enzymatic nitrate quantification and water quality, or for solar-powered waste recycling.

“The results of this study are promising and indicate a need for future work,” said Veerapandy. “The approach used in this study should be used on other PV materials to ensure that the results can be generalized and are not only valid for crystalline silicon.”

The research co-author said the lamination approach could be further compared with polymers used for front, rear and sandwich coatings and the technique could be tested for durability and under UV-accelerated conditions.

The pouch lamination method was presented in the paper Demonstration of a simple encapsulation technique for prototype silicon solar cells, and published on the ScienceDirect website.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.