From pv magazine 04/2020

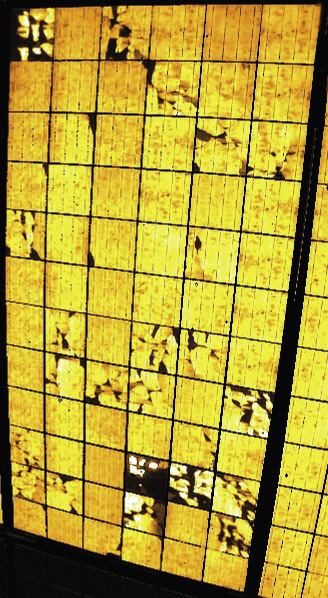

Electroluminescence (EL) images show contrasting dark and light regions of the cells inside PV modules: “Good” energy-producing regions appear light, while “bad” inactive regions with defects appear dark. When the EL camera has sufficient image resolution, it can also reveal cracks, microcracks, and other cell-level defects that are not detectable using visual or infrared/thermographic inspection tools.

EL testing provides another layer of diagnosis to help asset owners quantify the full extent of damage to PV modules – even when system underperformance due to microcracks is anticipated but has not yet occurred. For example, branching microcracks can result in breaks in the cell metallization, leading to the potential propagation of inactive areas and hotspots. In some cases, months or even several years may pass before cell cracks become hotspots and start to reduce system performance, but earlier detection of these latent defects is often critical for asset owners – especially when filing insurance claims or evaluating projects for acquisition.

Tech improvements

While the role of EL imaging in manufacturing and laboratory testing is well known, its use as a field inspection technique to assess solar module damage and power plant underperformance is less common. When the technology first moved into the field, it was used only at night because sunlight interference during daytime hours resulted in unusable images.

Nighttime EL testing in the field still offered several advantages as owners could test PV modules in-situ, while avoiding possible degradation or damage to the modules during dismounting, transportation, handling and remounting. But nighttime field EL testing has remained a niche practice, primarily because employing imaging crews and electricians for nighttime testing could be cost-prohibitive. Testing at night also introduced safety issues.

Fortunately, two recent improvements in the technology have made the use of daytime onsite EL imaging more practical and economical:

- Indium-gallium-arsenide (InGaAs) semiconductor detector. While most EL systems are based on a silicon detector, the material does not absorb near-infrared light well, resulting in distorted daytime EL images using that technology. InGaAs is a direct bandgap material, making it an ideal choice for daytime EL, as it greatly reduces the time of exposure required to obtain a high-quality image.

- Lock-in system. In order to filter out the near infrared light from the sun and capture a useful EL image, today’s more advanced EL technology uses a lock-in system. An electrical box plugged into the module string injects a small electrical pulse. This small oscillating electrical waveform causes oscillating EL light-emission-enabling software to filter and subtract light that isn’t emitted from the module.

Thanks to these two unique features in its advanced camera and testing system, PV Evolution Labs (PVEL) can quickly perform onsite EL inspections during daytime working hours. Working during the daytime also increases the number of modules that can be imaged per shift, often by more than a factor of three or four.

To maximize throughput, power can be applied at the string level (up to 1,500 V) and each module in the string can be EL-imaged. For other sampling, power can be applied at the module level to test individual modules. If necessary, select modules can be identified and removed from the array for further lab testing.

When and how?

Four key use cases have emerged for the use of daytime field EL testing:

- Establishing baselines, EPC acceptance and system health at site commissioning: Field EL imaging of a statistical sample of the site is used to confirm that modules were not damaged during transportation or installation. It also establishes a microcrack baseline for potential insurance claims in the future.

- Investigating plant underperformance: When O&M operators are unable to diagnose system underperformance with visual inspections and other more conventional tools, field EL can be deployed to identify latent PV module and cell damage.

- Assessing module damage after major weather or other force majeure events: In these cases, field EL is particularly useful in combination with aerial infrared imaging and visual inspection. Asset owners can use thermography and visual inspections to first locate the problem areas of their sites, then drill down on those specific areas with EL testing to identify damaged modules.

- Evaluating operational plants for acquisition. When acquiring an operating asset, the buyer should evaluate the integrity of the PV modules. Widespread cell cracking that is not detected will likely result in underperformance in the future.

EL imaging can capture a number of defects and signatures of module underperformance when conducted on a project site, including cracks and microcracks caused during transport, installation issues, and severe weather or other force majeure events, such as hail, windstorms, and flooding. It can also identify manufacturing defects such as broken grid lines (faulty printing), inadequate process conditions, poor quality silicon materials, potential induced degradation (PID), and light and elevated temperature induced degradation (LeTID).

Once the EL data is gathered, the images are quickly analyzed using sophisticated algorithms to pinpoint areas of damage propagation. The offsite image analysis categorizes the microcracks and other defects into low-, medium-, and high-risk “buckets,” depending on the power loss. Further lab analysis also leads to a deeper understanding of the EL signatures of different module degradation and failure mechanisms.

About the authors

Andrew Sundling is head of downstream business development for PVEL. He works with banks, developers, and asset owners to de-risk their PV and storage investments with data produced by PVEL’s comprehensive test programs and strategic consulting services.

Tristan Erion-Lorico is head of the PV module business for PVEL. He collaborates with PV project developers, investors, research institutes, and manufacturers to develop innovative performance and reliability test programs that produce independent data to support the downstream solar market.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.