When dust accumulates on the surface of a PV module it can block the sunlight and reduce power output. The Middle East is high in dust accumulation, and the region requires a balance between sustainability in terms of costs from dust mitigation and the maximization of generation from PV arrays.

Four main categories for dust-control solutions:

Electrostatic removal: a solution that involves applying a coating to the solar module to prevent dust buildup

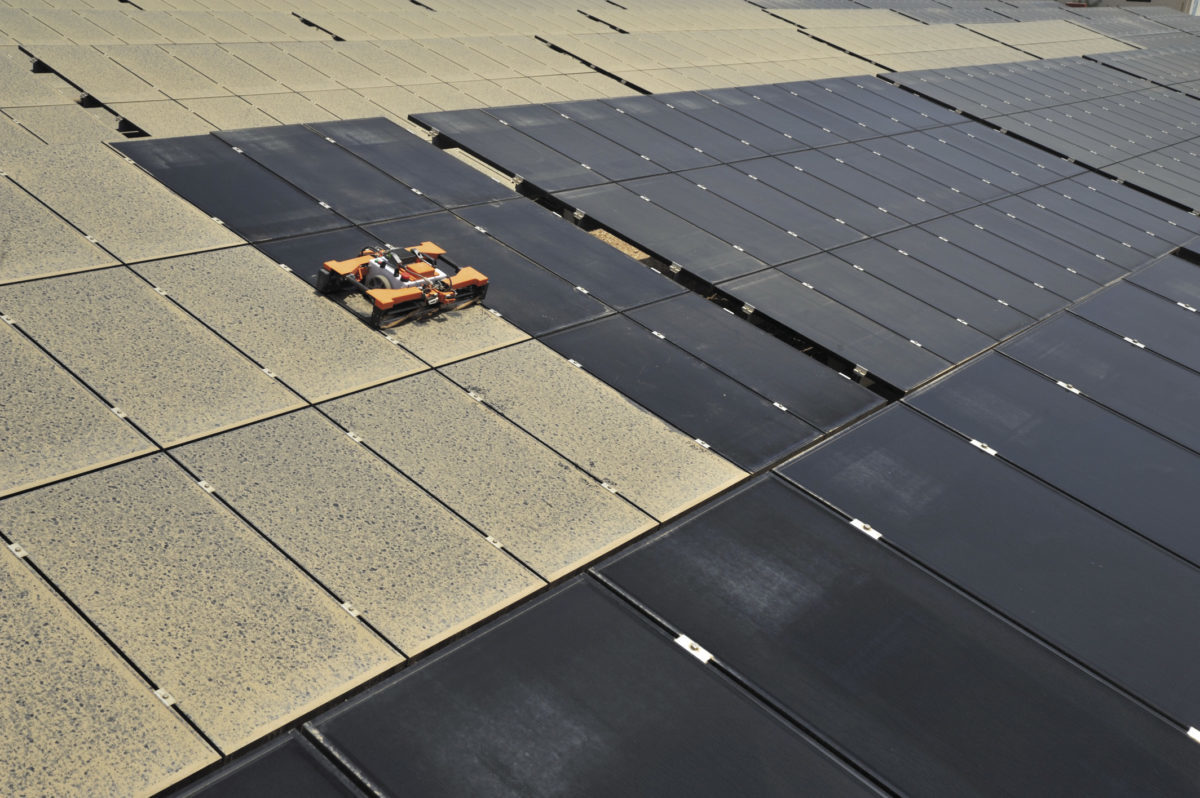

Mechanical removal: solutions based on robotic or mechanical cleaning

Natural removal: a solution based on natural cycles to remove dust by changing the alignment or taking advantages of aerodynamics

Handwork removal: solutions based on the deployment of O&M crews to clean modules

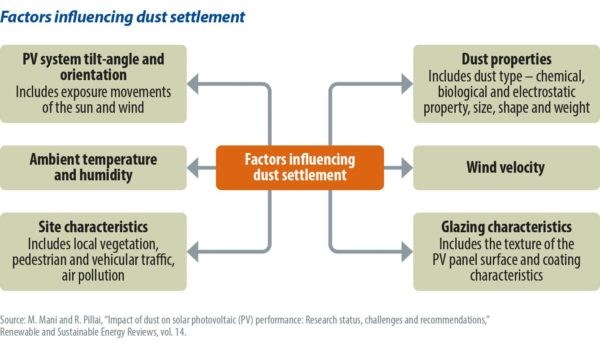

The right way to perceive the challenge starts with the preparation of technical definitions for the factors that are involved, in addition to clear measurements. “The choice of the location involves setting some parameters … the distance from the place of production of the components” and yield Fabio Magrassi wrote in a paper published last year in the Renewable Energy journal. In the Middle East, such locations tend to be in the desert, which results in efficient project economics and power output.

In these kinds of desert applications, single-axis tracking systems are frequently used. The orientation of the module surface on the tracker is affected by the dust properties. The orientation is also related to airflow – for example, if the flow of air (wind or storm direction) can be predicted, project engineers can take advantage or avoid disadvantageous aerodynamics.

There is some hard scientific data outlining the impact that dust can have on PV performance. In one 2017 paper, Athar Hussain, Ankit Batra and Rupendra Pachauri claimed that a 60% reduction in PV panel performance could occur because of dust accumulation. Their experiments included seven samples compared to a sand sample from Badarpur, India. The paper, which was published in Renewables: Wind, Water, and Solar, also pointed to a figure of 4.4% mean value of daily reduction because of dust in the absence of rain.

Definition of dust

Dust is a term that generally applies to minute solid particles with diameters of less than 500 µm. Its criticality comes from the ability to affect the permittivity of the PV surface. “Recent changes in climates give rise to regular dust storms around the globe, particularly in the Middle East,” Mono Mani and Rohit Pillai wrote in a 2010 paper on the subject. By permittivity, it is meant that the dust can partially reduce the sunlight on the surface, but not necessarily block the sunlight entirely. Dust is not uniformly distributed on the PV panel or the module surface. Consequently, this lack of uniformity impacts both the cleaning cycle (managerial perspective) and the glass surface (technical perspective).

Search for solutions

Many researchers are racing to win the challenge of effective dust mitigation. Hussain, Batra and Pachauri have demonstrated a range of solutions by different researchers in their work. In one experiment, for example, the researchers found that water cleaning with brushes was the most effective method in terms of results. They also noted that in the dry season, the efficiency of this method reached 97.2% and even beyond. An alternative method to control dust on the surface of panels was examined by Bekir Sami Yilbas, in a 2018 paper published in the International Journal of Energy Research. Yilbas examined a “new coating towards dust repelling with enhanced optical transmittance characteristic.” The method requires changing the texture of the module surface, but also adds costs. The study, which attempts to show how environmental dust influences solar energy harvesting, did not mention the specific duration of the study. However, it referred to a collected sample from the Arabian Gulf (Persian Gulf), where panels are exposed to solar radiation for prolonged periods of time.

In their work, Mani and Pillai provide a helpful tool to determine the cleaning cycle of the PV module, based on an experiment that considers the climate zone, cleaning recommendations, and the conditions for lower dust accumulation, such as tilt angle. For a location in the Middle East, this study on the impact of dust in PV spanned a particularly long period of time, from the 1960s to the 1990s. Although the reviewed studies present solutions and/or recommendations, only one provides a tool that is ready to be applied. This tool controls module cleaning costs by helping to determine maintenance times.

Future evolution

In the future, we expect more modules with self-cleaning capabilities in the market. This solution provides an ideal way to reduce the need for additional external cleaning. Mechanical cleaning is also proving popular, as robotic solutions are attractive for many current PV owners because they lower the need to replace existing modules. However, it should not be discounted that it is possible to use weather conditions to get rid of dust by exploiting aerodynamics accompanied by minimized cleaning cycles, although this approach requires more data from long-term studies. In general, all factors affecting the performance of PV modules should evolve as studies are conducted.

About the author

Zulfa Rasheed is a graduate of the Rochester Institute of Technology (RIT). She recently completed a 2018-20 study at RIT to convert the energy consumed by a ready-mix concrete producer to solar PV. Rasheed is a former UNESCO student researcher, with a focus on Ethiopia and the United Arab Emirates. She has worked as quality auditor with the Federal Competitiveness and Statistics Authority, a state entity in the UAE.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.