From pv magazine 01/2020

Bifacial technology offers project owners the chance for a significant boost in energy yield. But unlike some other innovations in module technology, this boost is entirely dependent on how the modules are installed and maintained within the PV system. A clear understanding of how a bifacial module behaves in the field is needed to ensure its performance. And though this could be said for any PV system, with bifacial the factors affecting performance multiply considerably compared to a single-sided installation, so gaining this understanding is no small feat.

“You have to consider the complicated shading of the ground and the even more complicated way different points are irradiated by diffuse light,” explains Bas Van Aken, a scientist in PV module technology at Netherlands-based research organization TNO Energy Transition. “Each point on the ground has different angles and distances to the PV panels, and mounting structures which are obstructing the view of the sky and the horizon.”

TNO is one of several players working on accurately simulating the behavior of bifacial modules in the field, and its ‘Bigeye’ model takes into account various types of rear side shading, as well as temperature, row length, and edge effects, angle-dependent reflection and more, in both fixed-tilt and single-axis tracker systems. The influence of these and other factors can inform various aspects of system design, including ground coverage ratio, total DC system size, DC/AC ratio, module height, and more. And the optimal setting will vary depending on climate, business model, and other site and project-specific factors.

Accounting for albedo

The most challenging factor to understand, and one that has among the most significant influences on total energy yield, is the albedo of the surface below the installation, and the way light reflects from the ground onto the rear side of the module. And models need to develop to include these additional parameters.

“Presently accepted yield models lack in bifacial modeling performance, with too many assumptions and simplifications that they do not ‘need’ for monofacial PV systems,” says Van Aken. “They have to take on board ‘enough’ bifacial modeling refinements to get their prediction within acceptable limits of observed field data, based on large-scale solar farms.”

PVSyst, widely considered the industry standard modeling software, has added a bifacial model to its package. This model allows users to add additional factors to the simulation – ground albedo and installation height being the most influential – and uses these to calculate rearside irradiance. The model then multiplies this by the module’s bifaciality factor, and the result is added to the frontside irradiance to give a figure for ‘effective irradiance.’ For ground albedo, the model allows for a single annual entry, or monthly values to reflect seasonal changes to a surface.

Approaches to bifacial simulation differ on the number of these additional factors taken into account for simulation. PVSyst takes a two-dimensional view factor approach, which divides the ground into small areas, and calculates the incident light reflected to the rear of the module. Non-uniformity of the rear side irradiance is accounted for later on using a rear side mismatch factor.

TNO’s Bigeye also uses the view factor approach, but in three dimensions to account for the edge of row effects, and can also incorporate shading and reflecting objects located behind the modules, such as a torque tube. PVSyst considers rows that are ‘infinitely’ long – an approach that is well suited to regular and long rows, but one that reaches its limitation when simulating shorter rows or individual modules.

Other approaches take an even more complex three-dimensional ray-tracing approach, which models each ray of light that can hit the front and rear side of the module, and calculates how much light is absorbed and scattered back. Still, in many cases, such an approach proves too time-consuming. “Detailed 3-D ray tracing models are showing great promise for being able to simulate the light conditions within a complex array geometry. However, for these models to be very accurate, we will need to measure the optical properties of all important materials at the site,” explains Joshua Stein, PV performance lead at Sandia National Laboratories. “These models also require large computing resources and can take hours or even days to run, depending on the details included.”

More data is needed from large-scale bifacial installations to validate these models, particularly regarding albedo and non-uniformity of rear side irradiance. However, indications so far are that PVSyst’s methods provide good results, and data from both ray tracing and actual installations will continue to inform this approach. “There is, as always, competition between the perfectionist, determining the ‘exact’ albedo of a given surface with/out coverage, and the practical person that needs to know how much light will be scattered towards the bifacial modules,” says TNO’s Van Aken.

Making the measurements

In monofacial monitoring, albedo is not a key consideration; PVSyst measures ‘far’ albedo for the area surrounding a project, rather than a direct measurement of the ground below, and a default value of 20% is considered sufficient. Some models also rely on satellite data, and there are multiple efforts underway to create a database of global albedo values. While useful in informing decisions on a broad region to look more closely at bifacial projects, this data will not take into account shading or other site-specific conditions, and onsite measurement is necessary to form an accurate picture. “To describe in fine detail what is happening on your PV farm,” says Van Aken, “you will need albedo values with the same frequency as irradiance, temperature, and wind data.”

Measuring albedo is complex for several reasons. Firstly, it cannot be taken as a constant value. Even slight changes in the color of the ground can have a significant effect. So for projects installed above grass or mud, there will be considerable seasonal changes, and even above concrete or gravel, rain or dust can bring about changes in albedo, along with the actual light conditions. “Typically albedo is taken as a single value, maybe varying over the seasons with snow or vegetation coverage,” explains Van Aken. “But there is an increasing amount of literature emerging that the effective ground-reflection also depends on the angle of the direct light with the ground surface and the ratio of direct to diffuse light.”

Even defining the term albedo has proved problematic for the industry. While it is now widely accepted that onsite albedo measurements are necessary for accurate simulation, there is no overall consensus on how it should be measured or the number and frequency of measurements needed to make a correct assumption for simulation.

In a white paper published earlier this year, Spain-headquartered tracker manufacturer Soltec sought to provide a practical guide to albedo measurement, based on data gathered at its Bifacial Tracking Evaluation Center (BiTEC) in California. The company notes that measurement points need to be representative of conditions across the whole site. Albedometers should be inspected and cleaned daily and recalibrated according to manufacturer guidelines. Soltec calculates a height between 1 and 2 meters as ideal for albedometer installation, with the option to adjust to ensure that the height from the surface is constant, even with snowfall or vegetation growth.

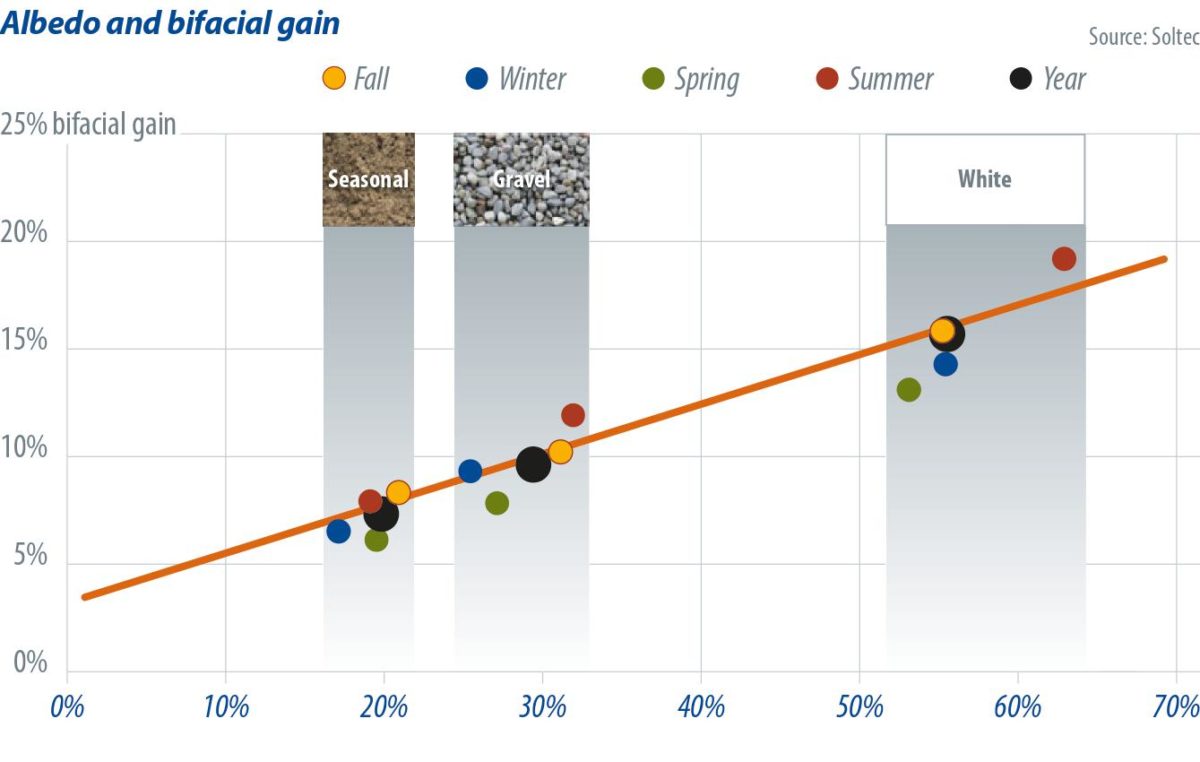

Soltec’s research reveals a linear dependency between albedo and bifacial gain. It divides surfaces into three broad categories of albedo to demonstrate this. White surfaces, with measured albedo of 55.6%, afforded a bifacial gain of 15.7%, while gravel with an albedo of 29.5% saw a 9.6% bifacial gain. For grass (seasonal) with 19.9% albedo, the bifacial gain was 7.3%. The figures (presented in the chart to the upper right) are based on one year of data from BiTEC installations utilizing Soltec trackers.

Future optimization

Results from the many bifacial test sites around the world continue to reveal more and more about the role of ground albedo in bifacial installations, and the opportunity for albedo-enhancing ground cover materials to significantly boost a project’s energy yield is clear.

Converting this into a large-scale solution, however, will be a whole new challenge for the industry, with many different approaches including plastic/fabric sheeting, spray-on materials, and selected vegetation with reflective leaves or flowers all to be evaluated. Their benefits need to be weighed against both installation and operation costs, along with broader environmental impacts.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Structural design details provide

Thanks for finally writing about >The long read: All about albedo

– pv magazine India <Loved it!

List of Alternative Linksbo Hyperlinks

Today is progressively developing, which makes it

easier for people to accessibility computerized networks.

Till now there are numerous online gambling games that may be played by

anybody online. Therefore, betting lovers no longer require to the casino to try out betting, this is pretty easy for them to be able to play anytime in addition to anywhere without limitations.