From the June edition of pv magazine

The last four to five years in technology upgrades, both to existing and new lines, among solar cell and module makers has required the implementation of laser processes. The first wave was aluminum oxide rear-surface cell passivation, which required laser ablation. Since then, the ‘back to the future’ implementation of selective emitter processes, enabled by cell metallization progress, required new laser tooling. And TOPCon requirements for laser boron diffusion appears to be an increasingly important focal point for development.

HJT cell cutting

On the module front, half-cut (HC) cell implementation – requiring laser cell cleaving, breaking, or separation tools either at the front end of module lines, or the back end of cell – has seen new laser stations added. And while HC processes might be thought to be relatively straightforward, the recent momentum behind heterojunction (HJT) technology is bringing with it new challenges.

“We have developed a new laser direct cleaving (LDC) process, using a full cut rather than a scribe and break, and it’s working very well,” says Toni Schmidt, Vice President Business Development at German laser provider Innolas. “We have developed a special, patent pending laser process where we are able to cut it [a full cell into two] with just one pass.”

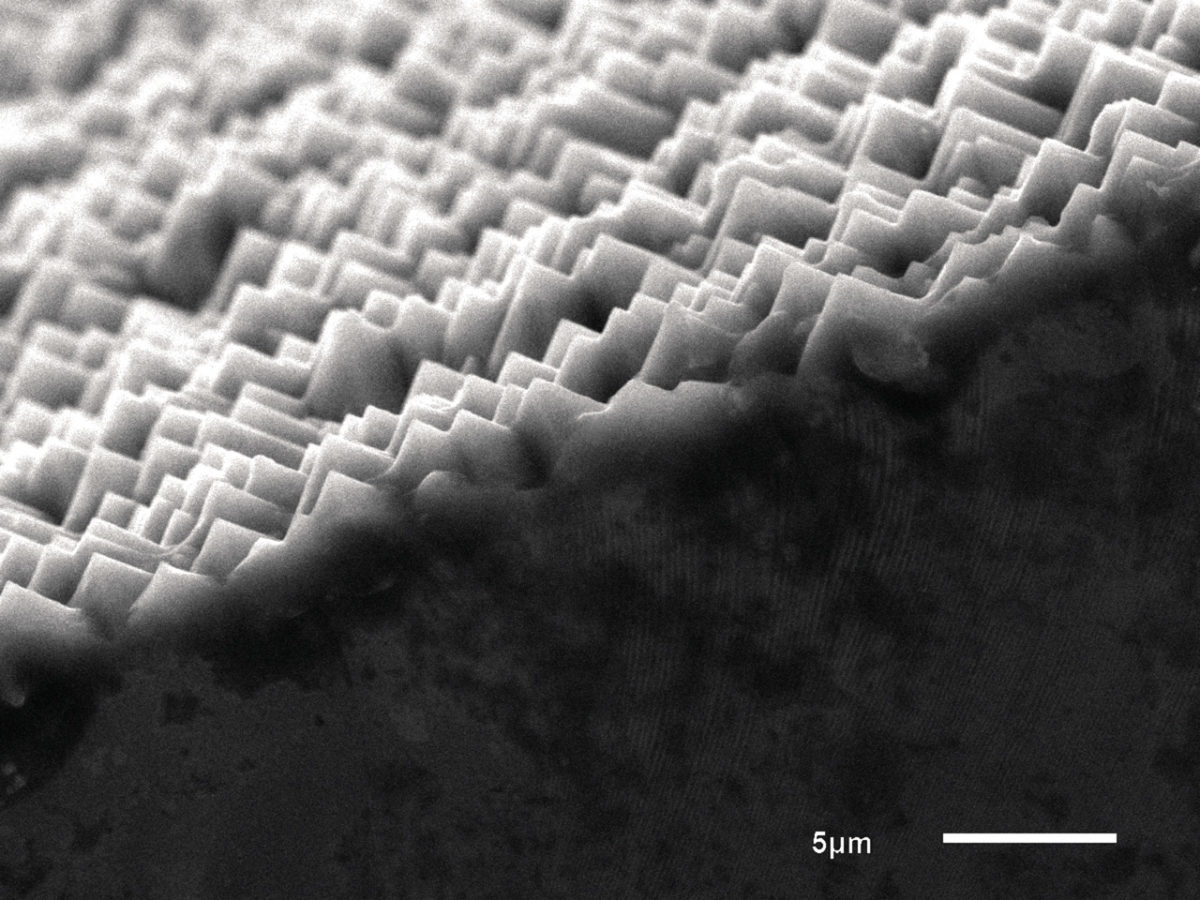

The amorphous silicon (a-Si) layer in HJT cells is sensitive to temperatures in excess of 200°C, making low-temperature HC production processes an imperative. And as with all high-efficiency cell architectures, any impurities introduced during the cutting can negate output gains made in the cell production itself. Innolas claims that its new LDC process is advantageous due to the cut cells exciting no shunting or melt along the cut cell edge, and the fact that it is a dustless process – enhancing uptime and doing away with the need for exhaust systems.

The new LDC process from Innolas has been integrated into its new PV laser platform, called Lumion – which Schmidt describes as being “extremely cost effective, and fast.” It will be on display for the first time at the 2019 SNEC show in Shanghai. The Lumion platform does away with the highly accurate turntable system used in previous generations of Innolas tooling. Instead, Lumion uses a dual line approach that the company reports can achieve an accuracy of more than 15 microns at even higher speeds. Throughputs up to 7,500 wafers/hour can be achieved, up from 6,000. “We developed a special device to reduce the handling time,” says Schmidt, “which really makes the difference.”

HC expansion

Compatriot cell process supplier 3D-Micromac says its thermal laser separation (TLS) process for half-cut cell production is well suited to HJT. “We already have customers for half cell lasers for heterojunction,” says 3D-Micromac’s Solar Product Manager Frederick Bamberg. “Due to thermal separation and no ablation, there is nearly no damage from heat.” 3D-Micromac’s technicians argue that TLS, in which a crack is precisely guided at much lower temperatures compared to ablation based processes, produces a higher mechanical cell edge quality than scribe and break. And the outlook for HC, says Bamberg, is particularly strong.

“Half-cut is going to be 70% of all modules in the next five years,” says Bamberg. “I think there is a lot of patent and IP issues with shingling and also questions about the mechanical stability of these shingled modules, and yield losses [in production]. But I definitely see a module power output increase of 5-7 W with half cells, and that increase is so easy to achieve with [the addition of] one laser and another stringer.” Bamberg adds that slowly but steadily increasing wafer sizes, in combination with efficiency boosting cell processes like improved wafer texturing and SE, make the case for reducing the cell current – further enhancing HC’s value proposition.

By Jonathan Gifford

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.