The 100 MW Veltoor Solar project in Telangana – owned by SE Solar Ltd, Suzlon’s special purpose vehicle with CLP India – has been awarded what is claimed to be the world’s first solar project quality certificate for a PV plant.

Carried out according to service specification DNVGL‑SE‑0078, it is claimed the certification is the world’s only global guideline for certifying PV projects.

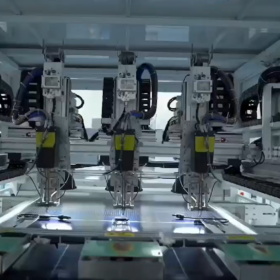

The certification to the Veltoor project encompassed an evaluation of the asset with an in-depth review of the design, grid code compliance, manufacturing process, transport and installation, commissioning and optionally in-service phases.

As Indian PV scales up to nearly 8 GW of installations this year, large-scale tenders multiply and new applications emerge; quality holds the key to India’s ambitious solar plans. Low quality PV equipment has maligned Indian solar projects and questions have been raised about the quality of the Chinese products that account for nearly 90% of solar imports into India.

The issues of solar product “dumping” by China and Malaysia, and sub-standard supplies, have been festering. Industry experts believe as much as 20-30% of imported modules may be sub-standard, even defective, with problems ranging from huge panel cracks to low-efficiency equipment.

Second hand Chinese panels going cheap

To meet cost and deadline pressures piled on by India’s relentless reverse-auction solar tendering system, some developers are buying cheap, poor quality Chinese modules, with smaller, tier 2 developers reportedly more likely to skimp on quality. The result is poor-quality projects with lower than expected power outputs.

To exacerbate quality concerns, second-hand Chinese solar panels – with efficiencies as low as 16% – are being sold at discounted prices. Carrying a one-year warranty, used A-grade panels which have been installed at the seller’s site for two months are being offered to developers at a substantial discount of as low as $0.25/watt (Rs17.92/w) on a cost, insurance and freight basis.

After the Solar Manufacturers’ Association filed an application in May, the commerce ministry initiated an anti-dumping investigation into imported of solar cells from China, Taiwan and Malaysia. The Directorate of Trade Remedies recommended a 25% safeguard duty on solar cell imports from China and Malaysia for the first year, followed by a phased down approach for the second year, although the duty is currently stayed by a court action.

Of late, the federal government has come up with stringent quality norms for solar equipment sold in the country, and has made the destruction of sub-standard equipment mandatory. Earlier this year, the Ministry of New and Renewable Energy passed an order mandating sellers and PV manufacturers to register products under quality parameters set by the Bureau of Indian Standards.

However industry watchers believe the new standards will not be any tighter than those of the International ElectroTechnical Commission. The only proposed difference is the inspections of solar project sites and a mandatory India-approved certification.

- pv magazine will host a quality roundtable at 2018 REI – the Renewable Energy India expo in Greater Noida. The event – on September 18, from 11am to 1pm, in the conference area of Sage Hall at the India Expo Centre – will discuss the role of new Bureau of Standards regulations and their expected impact on the quality of PV modules. Cutting edge PV applications will also be discussed, including floating PV and hybrid PV incorporating large-scale energy storage.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.