Though growth is on the way for n-type technology – it is expected to account for a 12% market share in 2021, p-type wafers, whether mono or multicrystalline, will continue to represent an 88% market share, according to the International Technology Roadmap for Photovoltaic (ITRPV) Eighth Edition 2017.

However, p-type cells can suffer from light-induced degradation (LID), which can significantly reduce the overall output of modules in the field due to degradation in efficiency. LID observed in silicon material, depending upon the cell type, is a degradation of bulk lifetime, which occurs within the first hours of light exposure.

Passivated emitter rear contact (PERC) cell technology is thriving, estimated to account for 56% of total silicon cell production by 2027, according to ITRPV. However, in several findings, PERC technology is more prone to LID than aluminum back surface field (Al-BSF) cells.

Moreover, in 2015, researchers from Fraunhofer ISE, Germany, also reported LID issues in n-type Czochralski-grown (Cz) silicon, and have presented methods to solve the issue.

BO-LID in monocrystalline Si

In the most prominent example of an LID mechanism, degradation occurs due to the activation of boron-oxygen (BO) defects in the boron-doped p-type Cz monocrystalline silicon, called BO-degradation or BO-LID. The degradation is more severe for high-performance technologies, such as PERC. The degradation results in a significant loss of power – relative power loss for the Al-BSF and PERC cell is typically 2–3%, and as high as 3–6% respectively.

Copper (Cu) contamination also causes a significant lifetime reduction under illumination, termed Cu-LID. Furthermore, the light-induced dissociation of iron-boron pairs in contaminated material is often observed in the context of LID.

Much research has been carried out, and the defects can be avoided with several techniques, either acting on cells after production, utilizing a so-called regeneration process, or actions at the ingot or wafer production stage. BO-LID can be resolved with different regeneration processes (or permanent carrier lifetime recovery), where a cell is treated with light intensity (excess charge carrier injection) at an elevated temperature. The values can vary according to the process, and a fast process developed by researchers was presented in the 33rd EUPVSEC conference held in September 2017 in Amsterdam.

Another approach to preventing the formation of BO complexes is to replace boron with gallium (Ga) as the dopant in the silicon crystals. At the conference, Longi Green Energy Technology Co. Ltd. from China, together with GT Advanced Technologies Corporation from the U.S., showed that replacing B with Ga as the dopant in monocrystalline PERC cells can eliminate LID. The research showed that LID can be controlled to <1% for cells with low base resistivity (<1 Ωcm).

Apart from p-type, Fraunhofer ISE has confirmed that illumination intensity and process temperature are both crucial for the regeneration process in n-type silicon. All of the solutions mentioned in this article are based on the recent findings from last year’s

EUPVSEC conference.

DZS Solar solution

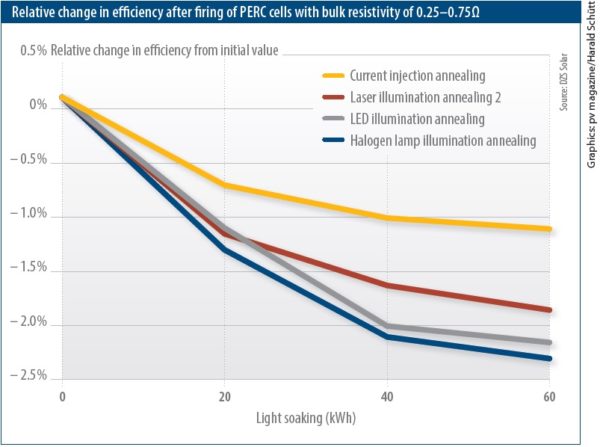

Dongfang Huansheng Photovoltaic Company (DZS), a subsidiary of Dongfang Electric Company, has compared several solutions to reduce LID in p-type monocrystalline PERC solar cells. It claims that current injection and laser illumination annealing with elevated temperature are potentially applicable solutions to mitigate LID in p-type PERC cells in mass production. The results from current injection annealing show that the relative efficiency degradation ratio is no more than 1.5% for samples with different bulk resistivity ranging from 0.25 to 3 Ω·cm.

Hui Li of DZS tells pv magazine, “Current injection has been used in the production line for mitigating LID on a large scale, especially for multi-PERC cells, and this method only uses electricity, so its cost of operation is lower than the light injection methods.”

Li also mentions that laser illumination annealing is currently used only in research, because of its high equipment price and low throughput, which are barriers to its use in large-scale production. “I think if the issues of throughput and cost can be solved, laser may be the promising method,” he outlines.

Light Scope by Fraunhofer CSP

Fraunhofer points out that an effective LID inspection for industry is essential to preventing electrical performance losses. Unfortunately, a standard LID test procedure at the solar cell level is currently missing. Moreover, the maintenance of the traditional degradation source – light – is challenging.

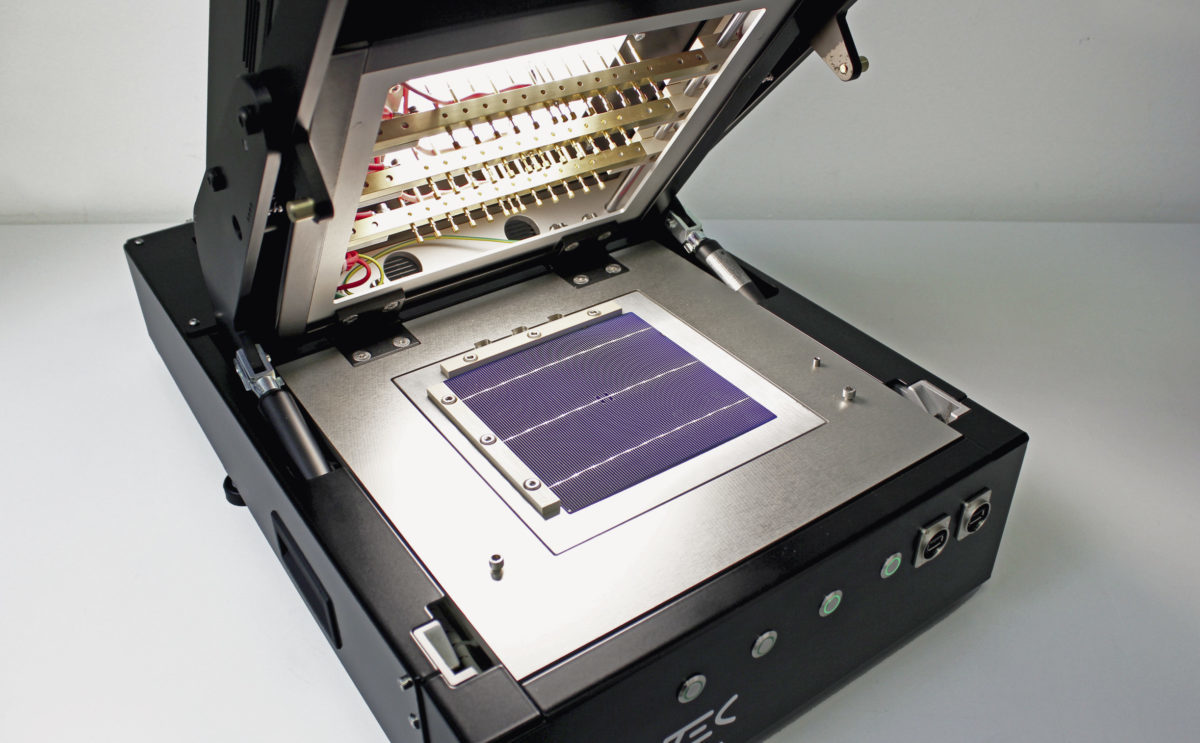

Fraunhofer Center for Silicon Photovoltaics (CSP) and LayTec AG have jointly developed an LID Scope measurement instrument, which they claim can perform rapid LID testing with high accuracy and reliability. Fraunhofer states that the degradation of a monocrystalline Si cell is completed within two hours, whereas it takes more than 30 hours for the mechanism to take place in a multicrystalline Si cell.

Chia-Mei Lin from Fraunhofer CSP, who handled much of the research, tells pv magazine, “The phenomenon of BO-LID is related to the formation and dissociation of chemical complexes, and thus can be explained with a kinetic model. Raising the temperature can lead to an increase of the degradation and regeneration rate according to the model. Our target is to build up an accelerated LID test procedure (a faster degradation/regeneration process). High temperature is therefore chosen as the accelerating factor.”

Lin also mentions that the machine is intended for cell-level testing and can be integrated into a factory line to test the LID level right after cell production. Moreover, at module level, LID can be examined through illumination or electrical methods.

Ultrafast in-line regeneration

Fraunhofer ISE, together with Rehm Thermal Systems GmbH, has developed an in-line ultrafast regeneration (UFR) process to prevent up to 98% of the BO-LID effect in mono-PERC cells, with a process time of less than four seconds.

Additionally, the institute has introduced a new parameter called regeneration completeness (RC). It quantifies the effectiveness of the regeneration process, independent of all overall efficiency, to allow a direct comparison of the quality of different regeneration processes.

To make the measurement more practical for use in large-scale production, it has also introduced another factor: practical regeneration completeness (pRC). Researchers mentioned that they have implemented this technology in an in-line production tool with industrial belt speeds of up to 10 m/min and achieved up to 86% pRC in preliminary tests. “To our knowledge, this is the fastest in-line LID prevention process available for manufacturing,” say researchers at Fraunhofer ISE.

LeTID in multicrystalline PERC

Light and elevated temperature-induced degradation (LeTID) is a defect observed by Schott Solar AG in 2012 in field conditions with temperatures above 60°C under illumination in multicrystalline PERC cells. It finds that, unlike BO-LID, the degradation is neither based on boron-oxygen complex formation, nor on iron-boron (FeB) pair dissociation processes. Moreover, Hanwha Q Cells GmbH, together with TU Bergakademie Freiberg, concluded that LeTID can cause 10% of power degradation between 100 and 1,000 hours of operation. Moreover, in some research it has been demonstrated that LeTID also occurs on mono c-Si, p-type cells. Until now, researchers have not been able to ascertain the main cause of the degradation and regeneration.

However, most recently, researchers from Fraunhofer ISE and Freiberg Materials Research Centre from Germany found that LeTID appears to be caused by defect complexes involving mobile hydrogen and an intrinsic crystal defect. This is ground-breaking research in finding the cause of LeTID in multi and monocrystalline cells. The research was also honored by the executive committee of EUPVSEC. It shows that the regeneration is strongly influenced by carrier injection conditions and elevated temperature.

Similarly, University of Konstanz last year presented the impact of temperature and doping on LeTID and regeneration behavior in PERC cells. The research measures the degradation in terms of difference in effective minority charge carrier lifetime.

The research mentions that the higher the temperature, the faster the samples degrade and regenerate. It shows that high temperatures are more effective at bringing about faster regeneration results. However, high temperatures show a second peak in carrier lifetime for both B and Ga-doped cells after 100 hours treated at 250°C – more than the initial carrier lifetime. However, it is not stable: It degrades again when tested again for stability at 75°C.

Jakob Fritz of the University of Konstanz Department of Physics explains, “Within the examined time scales, the second decrease in effective lifetime did not saturate. So, I unfortunately cannot tell you where it stops.”

Here also, researchers have observed that Ga-doped cells showed slower degradation than B-doped cells. However, when asked about suitable solutions for industrial scale, Fritz mentions, “since I wanted to examine the effect itself, I did not check how suitable materials or methods are for industry, or if it can be detected on module level before I-V testing.”

Industrial solution by GCL

GCL System Integration Technology Co. Ltd. (GCL SI), China, has tested and proposed some industrial solutions which can be adopted in mass production.

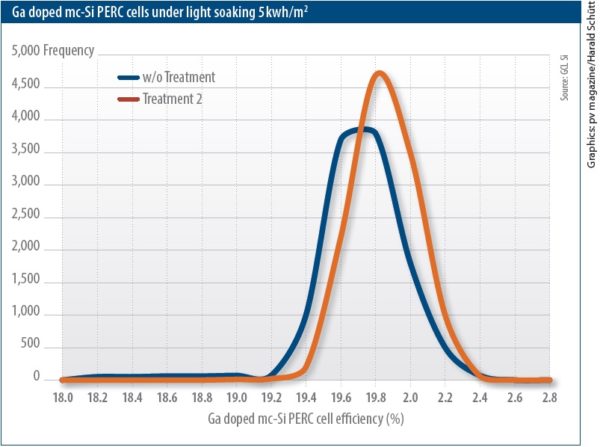

GCL SI has evaluated two different tests – named treatment-1 and treatment-2 – to mitigate the LeTID in p-type multicrystalline-Si PERC cells. In treatment-1, samples were treated at optimized temperature under light soaking of 5 kW/m², which shows LeTID decrease in the range 0.5% – 1%. In treatment-2, where cells were treated with increasing temperature and time, average LeTID decrease was nearly 1% post-treatment. GCL SI says that treatment-2 is much more suitable than treatment-1 to restrict the relative efficiency degradation below 2%. The exact details of the treatment processes have not been revealed by the company.

According to Jianwen Dong of the R&D Center at GCL SI, “Treatment-2 is a promising industrial solution and is applied in the mass production line already.” Further, in a pilot line treatment-2 has been tested for both B and

Ga-doped p-type multicrystalline-Si PERC cells. The test concluded that the average LeTID is about 1.1% and 0.8% after treatment respectively. Interestingly, treatment-2 also results in an efficiency increase of 0.1% absolute for

Ga-doped cells.

Several new methods and solutions have now been introduced to the market, and in the coming years LID should not be a big issue for manufacturers.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.