Beyond the hype: Why PERC still powers a stronger solar future

New doesn’t always mean better: Passivated emitter and rear contact solar cells have earned their place through real-world reliability and cost-effective manufacturability.

Solar technologies at crossroads

Experts set to speak at the NetZero Milan Expo-Summit 2025 on May 15 have told pv magazine that tunnel oxide passivated contact (TOPCon) will remain the dominant cell technology in the near term due to ongoing advancements, despite rising competition from back-contact and heterojunction technologies.

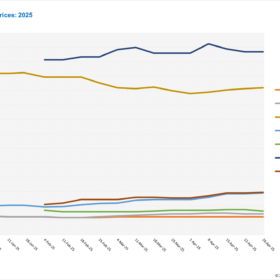

China module prices bearish, U.S. prices rise on tariff policies

In a new weekly update for pv magazine, OPIS, a Dow Jones company, reports that TOPCon modules from China held steady at between $0.085-0.090/W. It also reveals that Europe prices for TOPCon modules of over 450 W rose by 0.96%, assessed at €0.105/W.

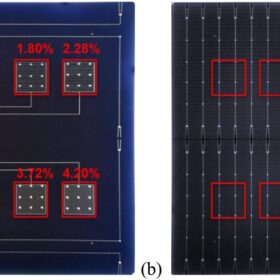

Jolywood’s laser-assisted firing process increases TOPCon solar cell efficiency by 0.6%, says UNSW research

New research from the University of New South Wales have found that the Special Injected Metallization (JSIM) technique developed by Chinese manufacturer Jolywood can considerably increase TOPCon solar cell efficiency. The scientists described precisely how laser-assisted firing enhances cell performance, reportedly filling critical gaps in industrial TOPCon cell optimization.

DAS Solar plans 3 GW solar module factory in France

Chinese manufacturer Das Solar says it will open its first European PV panel assembly plant in Mandeure, eastern France, by the end of 2025.

Solex 2 GW TOPCon cell line to come online by early 2027

Gujarat-based Solex Energy has initiated the work on its state-of-the-art 2 GW n-type TOPCon solar cell manufacturing facility, with operations slated to begin in early 2027.

Current UV tests overestimate TOPCon solar module degradation

Fraunhofer Institute for Solar Energy Systems ISE (Fraunhofer ISE) has found that current UV testing methods overestimate degradation in tunnel oxide passivated contact (TOPCon) solar modules, as dark storage after UV exposure causes temporary efficiency losses that largely reverse under sunlight.

Solex Energy’s new 2.2 GW solar module line to start production by October

Solex Energy Ltd is ramping up its solar module production capacity to 4 GW with the addition of a 2.2 GW line. The new production line is set for completion by September.

India added 25.3 GW of solar module and 11.6 GW cell capacity in 2024, says Mercom

Domestic manufacturers added 25.3 GW of solar module manufacturing capacity in 2024, taking the nation’s panel capacity to 90.9 GW as of Dec. 31, 2024.

Acme Group targets INR 10,000 crore revenue from solar cell, module manufacturing business by 2030

Acme Group plans to scale the manufacturing capacity of its recently commissioned 1.2 GW solar module factory as well as establish a PV cell facility under its new business entity Acme Renewable Equipment Manufacturing.