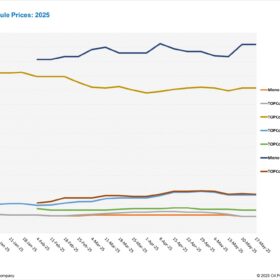

Non-stop solar innovation despite module oversupply

It’s no secret that prices throughout the solar supply chain have been at rock bottom over the past 18 months. Alex Barrows and Molly Morgan of CRU Group explore how the market reached the imbalance that caused PV prices to crash, what this has meant for innovation, and how it might affect future technology transitions.

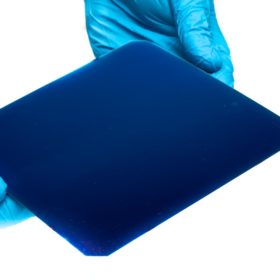

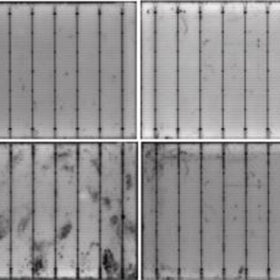

Combined indoor, outdoor testing shows sensitivity to moisture in TOPCon PV modules

Researchers at the Fraunhofer ISE have combined indoor and outdoor testing to understand and quantify degradation processes in TOPCon solar panels. The novel methodology is intended to provide data for validating and improving stress laboratory protocols.

SAEL to set up 5 GW solar cell and module manufacturing facility in Uttar Pradesh

SAEL Industries Ltd will invest around INR 8,200 crore to establish a 5 GW integrated solar cell and module manufacturing facility in Greater Noida, Uttar Pradesh. Once operational, it will take SAEL’s total solar manufacturing capacity to 8.5 GW.

Tongwei achieves 91.7% bifaciality factor for 722 W TOPCon solar module

The Chinese manufacturer said the result was confirmed by TÜV Rheinland. It was achieved through a sunken pyramid structure that reportedly achieves selective-texture on the non-electrode area of rear-side and a zebra-crossing passivation contact structure that is said to ensure excellent passivation.

WorldOne Energies to set up 1 GW solar module factory in Canada

WorldOne Energies has announced plans to establish a 1 GW solar module manufacturing facility in Ontario, Canada, marking a major step in its global expansion beyond India. The facility will produce TOPCon bifacial modules and cater to the North American market.

Trinasolar targeting ‘high-value’ markets

Yang Bao, Trinasolar’s president of global sales and marketing, recently spoke with pv magazine about the company’s strategy for the solar and energy storage business.

Ahaan Solar advances 2 GW solar module factory in Haryana

Utilizing advanced tunnel oxide passivated contact (TOPCon) technology, Ahaan Solar’s factory in Haryana will produce high-efficiency solar modules for both domestic and international markets.

China module prices steady amid bearish outlook

In a new weekly update for pv magazine, OPIS, a Dow Jones company, reports that TOPCon modules from China held steady at $0.083/W. Meanwhile, the spot price for U.S. TOPcon modules over 600 W was assessed this week at $0.263/W.

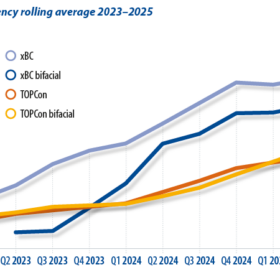

From TOPCon dominance to the rise of back-contact solar modules

Having invested heavily in TOPCon, solar manufacturers in India are beginning to explore hybrid solutions such as BC-TOPCon as a bridge between TOPCon and back-contact (BC) technologies. These hybrid models could ease the transition to BC by enabling manufacturers to leverage existing infrastructure while incorporating more efficient designs.

Researchers warn of ‘hidden contaminants’ that could increase TOPCon, HJT solar module humidity-induced degradation

Australian researchers have identified five contaminants that could increase damp heat-induced degradation in TOPCon and heterojunction cells and modules. Their analysis has shown these contaminants could originate from improper handling during cell or module processing.