The long read: Bifacial drives encapsulant switch

Suppliers of encapsulant materials – plastic sheets that are heated to laminate together the components in PV module stacks – are rapidly expanding to keep pace with module manufacturing in Asia and other parts of the world. Ethylene-vinyl acetate (EVA) continues to dominate the market, but new developments in module technology are driving a slow shift to more costly polyolefins.

Solar EVA sheets attract AD duty for five years

Following a petition by domestic manufacturers seeking legal protection under anti-dumping laws, the Directorate General of Trade Remedies has recommended the imposition of duties ranging from $537-1,559/metric ton on solar ethylene vinyl acetate sheets imported from China, Malaysia, Saudi Arabia and Thailand.

Government initiates anti-dumping investigation for the imports of EVA film for PV modules

RenewSys India has filed an application before the Directorate General of Anti-Dumping & Allied Duties for the imposition of anti-dumping duty on imports of ‘Ethylene Vinyl Acetate (EVA) Sheet for Solar Module’ from China PR, Malaysia, Saudi Arabia, South Korea, and Thailand.

A multi-layered battle

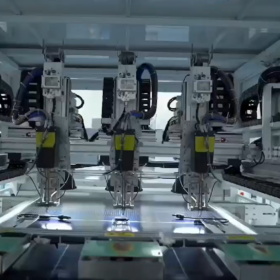

Lamination innovation: The ongoing ambition of laminator manufacturers is to develop machines that can deliver high output through a faster lamination process, while simultaneously reducing their footprint by combining several machines into one. However, an in-depth process know-how is essential in order to produce defect-free modules. Which players possess such knowledge?