The long read: Battery material concerns

Shouldn’t we all be driving in affordable electric cars with 800-plus kilometers of driving range by now? Surely yes, according to many of the announcements coming from battery scientists over the past decade. Yet for all the scientific breakthroughs, few in fact “break through” into commercial applications. Christian Kuss of the University of Manitoba makes the case for a holistic approach to battery materials development, and reminds us to look beyond the stars of the show and consider their interactions with the auxiliary materials that hold the whole thing together.

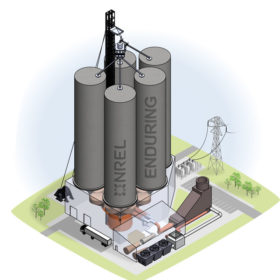

Storing wind, solar power with silica sands

NREL researchers developed a system that uses heated silica particles for thermal energy storage. The baseline technology is designed for a storage capacity of up to 26,000 MWh and is claimed to have a cost of of between $2 and $4 per kWh.

Lithium-ion vs lead-acid batteries

An international research team has conducted a techno-economical comparison between lithium-ion and lead-acid batteries for stationary energy storage and has found the former has a lower LCOE and net present cost. Through their analysis, which was performed assuming the use of the batteries in connection with a 10 kW, grid-tied PV system, the scientists concluded that lithium-ion batteries are the most viable solution.

Adani Green Energy raises US$ 750 million from issuance of green bonds

The solar developer shall utilize the proceeds towards equity funding of the capex for its under-construction renewable projects.

Photovoltaic sunshade based on perovskite solar cells

The phovoltaic sunshade was deployed on the facade of a factory owned by Polish aluminum system provider Aliplast. The movement of the PV blinds is regulated by a controlling system linked to a weather station installed on the roof.

International group offers $68m loans for struggling off-grid clean energy distributors

‘More than 90’ suppliers of appliances such as solar lanterns and home solar panels, as well as mini-grid installers, will be offered low-interest credit by an assortment of government-backed and privately-financed entities.

Looking at the world’s largest solar power stations

Solar energy pioneer and founder of Wiki-Solar, Philip Wolfe updates his series of blogs on the world’s largest solar power stations, first published in pv magazine in 2019. At that time, there were no single solar power plants over 1 GWAC. The record now is 2.2 GWAC.

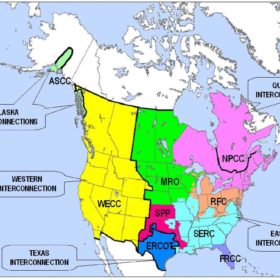

Cheapest long-duration storage for systems with high renewables

National Renewable Energy Laboratory researchers have studied which tech offers the lowest levelized cost of energy to provide the US Western Interconnection grid with electricity when wind and solar are not available. They assumed 85% renewables penetration and determined that geologic hydrogen storage and natural gas combined-cycle plants with carbon capture storage are the cheapest options for 120-hour discharge applications.

Novel battery chemistry for zinc-ion batteries

Scientists have demonstrated a zinc-ion battery that overcomes many of the challenges for this technology. By working with a highly-concentrated salt solution as the electrolyte, the group was able to achieve stability over more than 2,000 cycles combined with a strong electric performance. The group says that its work opens up “a viable route to developing aqueous batteries for emerging electrochemical energy storage applications.”

The long read: Hot thermal energy storage hopes

Thermal energy storage is dense, efficient, and suitable for greenfield and brownfield projects, with a potentially long lifespan. It can also be built with recyclable or low-impact storage materials. So why is it taking so long to achieve widespread commercial success? Tristan Rayner explores the latest developments.