In India, thyssenkrupp is the only manufacturer of the highest quality CRGO electrical steel. The company recently enhanced its production facility to make world class CRGO steel at its Nashik plant. The company now has the capacity to produce 50,000 tonnes of the superior grades of CRGO. Grain-oriented electrical steel is used wherever electrical energy is efficiently converted, transported and used, such as in distribution and power transformers.

Electrical steel is a key component of the upcoming switch to green energy

Electrical steel is at the core of the energy supply chain and is essential to the success of the energy transition. Future growth in the utilisation of renewable energy sources will make this effort even more challenging. Everywhere where electrical energy is effectively converted, transferred and used, such as in distribution and power transformers, grain-oriented electrical steel is required. Electricity transmission requires a higher voltage in order to be transported across long distances. Around a thousand times more voltage than what is found in home wall plugs is needed for transportation. The voltage must be converted once more before being used in homes and businesses. Transformers for power and distribution both essentially need CRGO steel. It helps to drastically lower greenhouse gas emissions if high efficiency steel is used in the cores of transformers. thyssenkrupp’s powercore® enables new and creative technology that helps to safeguard the environment and raise everyone’s standard of living, from smaller, higher performance transformers to lower noise emissions in urban areas. powercore® offers low loss grades like 23HP80D, 23HP85D, and 23HP90D in India.

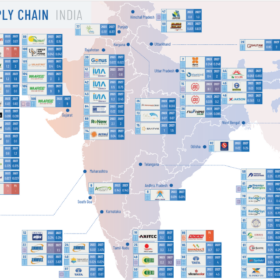

By providing high efficiency powercore to industrial applications and the power transmission network, thyssenkrupp directly contributes to energy savings. These energy-efficient products will continue to be developed as part of the company’s Make in India mission. The company has exported the high grade CRGO steel to more than 60 customers, in 22 countries spread across 6 continents.

The rise of green steel: Treading the road to sustainability

India’s path to net zero and decarbonization has pushed industries to adopt green steel and with the launch of CRGO, thyssenkrupp Electrical Steel has proved to become an industry leader in sustainable steel production. To be in line with the market and match with the stringent guidelines of efficiency issued by Indian utilities on steel, the company in a short span of time adopted the same strategy and successfully initiated the commercial production of 0.23mm in superior grades with low losses. This move has been appreciated by local OEMs and processors who were earlier completely dependent on imports, thereby contributing to the Aatma Nirbhar Bharat Mission of India.

thyssenkrupp Electrical Steel India will present itself at Elecrama in New Delhi between 18th to 22nd February 2023.You will find the booth of thyssenkrupp in hall 09, booth K5, India Expo Mart, Greater Noida.

About thyssenkrupp Electrical Steel

thyssenkrupp’s steel division is one of the world’s leading manufacturers of high-tech electrical steel. Its Electrical Steel business unit produces grain-oriented electrical steel under the PowerCore® brand, a core material for energy-efficient transformers and large high-performance generators. Over more than 50 years the business unit has built up extensive expertise in the production and use of grain-oriented electrical steel. Research and development departments in Gelsenkirchen (Germany), Isbergues (France) and Nashik (India) work to continuously improve the properties of the material. With the new production line at the Nashik site, thyssenkrupp is India’s first and currently only manufacturer of superior grade grain-oriented electrical steel.