Discover Battery unveils lithium ferro-phosphate battery for off-grid solar, tiny homes

At Intersolar North America in California, Canada-based Discover Battery has launched the Helios energy storage system, an LFP battery designed to operate in remote conditions.

Ohmium partners IIT Madras on PEM electrolyzer R&D

The USA-headquartered green hydrogen generator developer has entered into an R&D partnership with IIT Madras Research Park (IITMRP) to improve the performance and lower the cost of its polymer electrolyte membrane (PEM) electrolyzers.

Spraying water system for solar module cooling

A British-Indian research group has developed an active cooling technique that is claimed to improve a PV system’s yield by around 0.5%. The system could be used in residential solar arrays and the water heated by the PV modules may be fed into a solar water heating system.

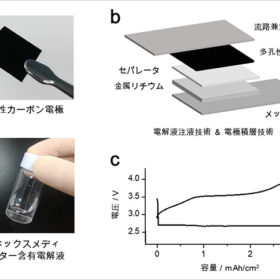

Japanese consortium builds lithium-air battery with energy density of 500 Wh/kg

A Japanese group has developed a storage system with potential applications in residential storage, electric vehicles, drones and Internet-of-Things devices.

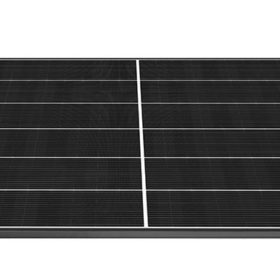

Panasonic unveils 410 W solar panel with 22.2% efficiency

The new heterojunction module series is compatible with Panasonic’s Evervolt battery and has a power output ranging from 400 to 410 W. It also features a temperature coefficient of -0.26% per degree Celsius.

The long read: Dealing with dust

Sand and dust are a PV plant operator’s worst nightmare. Performance losses due to soiling, or “the dust effect,” are a cause for innovation among O&M providers, particularly in dry and dusty regions that are otherwise ideal locations for large-scale solar installations. Yazeed Al-Mousa examines the latest robotic cleaning solutions, as well as the software and sensors that help plant operators with the tricky economic decision of when to actually start cleaning.

Residential building fully reliant on hydrogen for space heating, hot water

The campus of the Delft University of Technology (TU Delft) in the Netherlands is currently hosting a retrofitted existing building provided with heating by an H2 heating boiler in the attic. The boiler is linked to an underground hydrogen system.

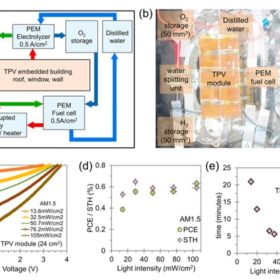

Solar-powered hydrogen for domestic applications via building-integrated transparent platform

An international research group has created a closed-loop, transparent energy platform based on PV power generation and hydrogen production from photo-electrochemical cells. The system is claimed to supply power without interruption and to be transparent enough to be integrated into buildings.

The long read: Finding PV faults faster

PV cell and module manufacturers are increasingly turning to artificial intelligence to monitor production lines and the products coming off them in minute detail. As inline monitoring and testing equipment become more sophisticated, cell and module makers must be prepared to manage the enormous amounts of data and pull out the points that will save them time and money. pv magazine examines the software solutions backing state-of-the-art PV production.

Electrolyzer tech to produce hydrogen from seawater

With a new start-up and a consortium in the Netherlands, German automotive supplier Schaeffler wants to significantly reduce the costs of green hydrogen.