Sustaining the battery storage supply chain

Noida-headquartered Lohum plans to expand its integrated lithium-ion battery manufacturing and recycling facility in India to 3 GWh and expand into the US with its first facility. Co-founder Justin Lemmon speaks to pv magazine about how their operations in India will solve the battery supply chain and cost challenge for the nation’s electric mobility and renewable energy ambitions.

Adani Green targets 45 GW renewable energy generation capacity by 2030

The renewable energy developer had an operational capacity of 5,410 MW (4,763 MW solar and 647 MW wind) as of September 30.

US Commerce Department throws out anti-dumping petitions

The dismissal is a win for the Solar Energy Industries Association, which vigorously opposed the request by American Solar Manufacturers Against Chinese Circumvention (A-SMACC) for anti-dumping and anti-circumvention (AD-CVD) tariffs

Modison Metals to expand into battery storage, EV charging in partnership with Russian firms

The electrical contacts manufacturer will join hands with battery storage firm RENERA and EV charger manufacturer L-Charge for its business expansion into these segments.

How PV performs close to radio, TV antennas

Researchers in Kenya have analyzed the performance of an off-grid PV system located near an isotropic antenna as an emitting source.

Shipping problems for First Solar but production line expansion is under way

The U.S. manufacturer has started building its third Ohio production base and has also begun ordering equipment to kit out its first factory in India.

End-of-life management of solar PV waste in India

A new study proposes an ‘extended producer responsibility’ based regulatory framework for end-of-life (EOL) solar PV management in India. Under the framework, the Government of India (GoI) works as the nodal agency, defining the roles and responsibilities of different stakeholders and regulating the overall supply chain. The onus of EOL solar PV take-back, transportation, storage, recovery, and destruction lies on the manufacturers, with the entire system cost borne by an executive committee formed by the manufacturers.

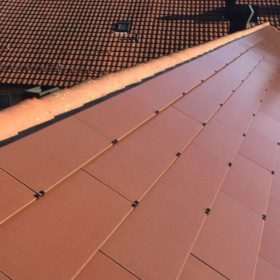

Solar tile with anti-glare coating from Switzerland

Swiss manufacturer Megasol said the new product is compatible with the most common tile formats and also available in different colors. Megasol has also developed a coating that eliminates the glare effect of solar modules.

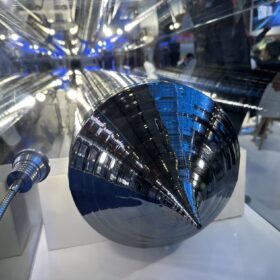

Insolight unveils 20.1%-efficient translucent photovoltaic panel for agrivoltaics

Insolight has developed a translucent monocrystalline solar panel with a nominal power of 106 W and a power conversion efficiency of 20.1%. The solar cells are covered with protective glass and optical lenses to concentrate and direct sunlight onto them at around 100 times the intensity of standard solar glass.

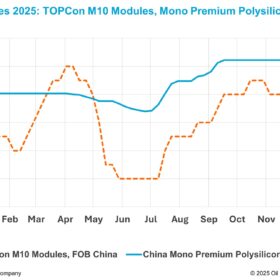

210mm wafer achieves highest energy yield, finds Trina Solar

Trina Solar has found that its Vertex modules, based on the 210mm wafer, achieve an energy yield up to 1.6% higher than rival products based on the smaller 182mm wafer format. The company conducted outdoor testing at two separate sites with varying climates, finding that products based on the larger format have a particular advantage in low-irradiance environments.