Waaree secures $2.37 billion of orders for 5 GW of bifacial PV modules

Indian solar manufacturer Waaree Energies has secured domestic and international orders to supply 5 GW of its bifacial 540 Wp and 600 Wp solar panels.

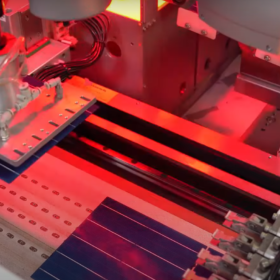

Adani Solar ranks as PVEL top performer for fifth consecutive year

Indian solar manufacturer Adani Solar has been ranked as a top performer in PV Evolution Labs’ (PVEL) 2022 PV Module Reliability Scorecard. The scorecard ranks PV modules based on lab and field test results for performance and reliability.

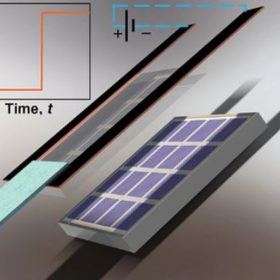

‘Pulsed Joule heating’ tech to remove snow, frost, ice from solar modules

US scientists have developed a way to remove snow and ice from solar panels at a much faster rate than conventional approaches. It is based on a glass coating on a film with high optical transparency and superhydrophobicity.

Small-scale floating PV with pumped hydro storage

Indian scientists have developed a system under which a pumped-hydro facility stores grid electricity during off-peak hours by pumping water to an upper reservoir. During peak hours, the system feeds the load, rather than taking power from the grid.

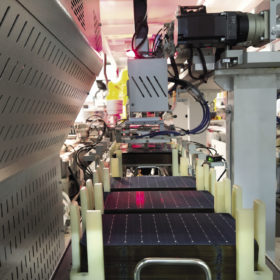

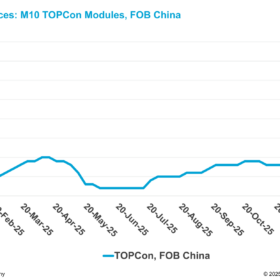

The long read: Decision time for India’s solar manufacturing plans

India is expanding solar cell production capacity in a big way. Will manufacturers go down the established mono PERC route or leapfrog to advanced n-type technologies? Uma Gupta investigates.

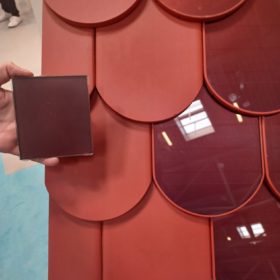

Terracotta solar tiles for historical buildings

Germany’s paXos, whose solar roof tiles were bought by Meyer Burger and unveiled last year, has shown off its new “Beaver Tail” terracotta solar tiles at Intersolar 2022.

Indian opportunity for renewable energy investments

In a keynote address at Intersolar Europe 2022, Indian Union Minister Bhagwant Khuba asked global investors to seize the opportunity to focus on India as it targets net-zero emissions by 2070 and 500 GW of installed non-fossil energy capacity by 2030.

JLNPhenix Energy expands lithium battery capacity to 550 MWh/year

Noida-based manufacturer JLNPhenix Energy has expanded its lithium battery manufacturing capacity in India to 550 MWh/annum, with the addition of a 150 MWh/year plant in Maharashtra.

Solis unveils off-grid PV inverter

The S5-EO1P(4-5)K-48 series off-grid PV inverter has an efficiency of 96.7% and supports parallel operation of up to 10 units, which allows for a system capacity of up to 50 kW. According to the manufacturer, the device is compatible with all top-tier brands of lithium-ion and lead-acid batteries.

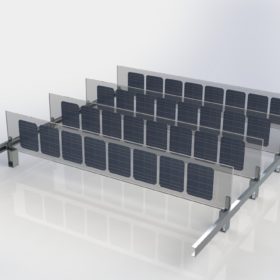

Vertical PV system for green rooftops

Norwegian startup Over Easy Solar AS is launching a vertical PV system for rooftop applications at this year’s Smarter E in Munich, Germany.