Vikram Solar secures 378.75 MW module order for Indian Oil-NTPC JV project

Vikram Solar has secured an order to supply 378.75 MW of n-type TOPCon solar modules for a project developed by Indian Oil NTPC Green Energy Pvt Ltd (INGEL), a joint venture between Indian Oil Corp. Ltd and NTPC Green Energy Ltd.

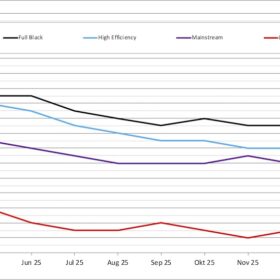

Solar module prices rise faster than expected in February

Solar module prices increased by €0.01 ($ 0.012)/W to €0.015/W in February, lifting levels 15% to 18% above the December 2024 low despite falling wafer costs, as manufacturers seek to restore margins after prolonged losses.

From panels to complete energy systems: The evolution of India’s rooftop solar market

Rooftop solar is moving from being a supplementary solution to becoming a central component of India’s energy architecture. The next phase of growth will not be defined by panel installations alone but by how effectively generation is integrated with storage, digital intelligence, and grid infrastructure.

Inside the PV recycling black box

How PV modules are treated at the end of their life is an increasingly important issue, but some recycling practices leave a lot to be desired. Scott Azevedo from Intertek CEA explores how asking the right questions, paying closer attention to end-of-life treatment, and steering volume toward good recyclers can have positive long-term consequences for the solar industry.

Global-warming-induced degradation could raise rooftop solar LCOE by up to 20%

A global study finds climate change will sharply increase high-temperature risks, accelerate degradation, and raise costs for rooftop PV, with economically disadvantaged regions hit hardest. Researchers warn current IEC standards underestimate future risks, urging urgent updates to avoid stranded assets and rising electricity costs.

Vikram Solar signs 2 GW PV cell deal with Jupiter International

Vikram Solar has signed the agreement to procure 2 GW of high-efficiency TOPCon and mono PERC solar cells from Jupiter International.

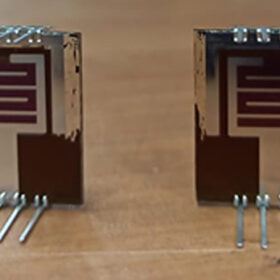

NexWafe, Talon PV sign 7 GW solar wafer supply agreement

Under the terms of the deal, Germany’s NexWafe will supply its ultrathin solar wafers to Talon PV’s planned 4.8 GW TOPCon solar cell manufacturing plant in Texas. Initial qualification work will take place at a pilot production line at Fraunhofer ISE’s Photovoltaic Technology Evaluation Center.

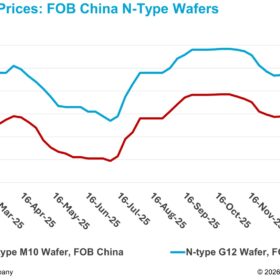

China wafer prices fall for fourth week as discounting deepens under inventory pressure

In a new weekly update for pv magazine, OPIS, a Dow Jones company, provides a quick look at the main price trends in the global PV industry.

SECI launches 870 MWp solar module tender

The Solar Energy Corp. of India (SECI) has issued a tender for the supply of 870 MWp of solar PV modules manufactured using domestically produced cells.

The effects of solar module elevation on ground-mounted PV

Scientists in Hungary found that ground-mounted PV modules at an intermediate elevation of 1.1 m achieve the highest efficiency and power output due to improved airflow and reduced cell temperature. Their study also estimated a levelized cost of electricity of $0.0843/kWh and 577.78 kg CO₂ mitigation over 25 years, while noting results are specific to concrete surfaces.