Solar tariffs could rise about 20% due to customs duty

The installation cost is set to increase as a 40% customs duty on solar modules, and 25% on cells, comes into effect from next year.

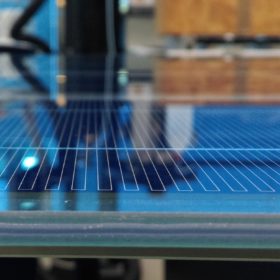

Trina launches 670 W solar panel

The latest product in the Vertex series from the Chinese manufacturer has a power conversion efficiency of 21.6%.

Solar manufacturer wants customs duty waiver to domestic sales by SEZ units

Domestic sales by manufacturing units located within special economic zones (SEZs) are treated as exports, attracting customs duty levy. This puts the SEZ manufacturers at a disadvantage compared to those in the domestic tariff area.

LONGi Solar was India’s biggest module provider in 2020

The Chinese manufacturer shipped over 1,500 MW (DC) of modules last year, accounting for a 15.6% share of the total 9,478 MW module supplies in the nation.

Silver accounts for 10% of PV module costs

The share of silver in the total cost of PV modules has increased by around 5% in recent months, according to US analyst Matthew Watson. He told pv magazine that silver prices are set to rise, adding that the metal will eventually account for an even larger percentage of overall module costs.

Borosil Renewables posts a 74.3% y-o-y revenue growth in first nine months

The Indian solar glass manufacturer reported net revenue of around INR 300 crore during the current fiscal’s nine months ended December 2020, with the best-ever quarterly earnings of INR 140 crore coming from the third quarter.

REIL seeks 150,000 multi-crystalline silicon solar cells

Bids are invited from Indian manufacturers to supply four-/five-busbar multi-crystalline silicon solar cells rated for 4.5W peak output. Bidding closes on March 15.

Indian researchers improve perovskite-based solar cell structure

A numercal study by researchers at India’s Chitkara University has shown enhanced charge extraction in metal-perovskite-metal back-contact solar cell structure through electrostatic doping. The proposed design yielded a 59.4% improvement in power conversion efficiency over previously reported structures.

Viridian Solar unveils roof-integrated solar panels with power of 335/340 W

The new devices feature efficiencies ranging from 20.7-21%. The panels are said to be compatible with a wide range of slates and tiles, include special fixings for different batten thicknesses, and achieve the highest fire rating and wind resistance without modifications to the roof.

Indian startup Solavio Labs raises Canadian fund

The solar panel-cleaning robot startup, which saw its sales jump 125 times last year, has thus far raised three levels of funding amounting to INR 2 crore from government bodies in India, Dubai, and Canada.