JinkoSolar was biggest module supplier for India’s Q2 PV installations

JinkoSolar modules accounted for 20% (528 MW) of India’s 2,662 MW DC of solar deployment in the April-May-June period of 2021.

Reliance Industries may acquire REC Solar

Mumbai-based Reliance Industries and REC Solar have declined to comment on rumors that the Indian company might acquire the Norwegian PV module maker, in a potential transaction that Indian media outlets have already valued at $1 billion to $1.2 billion.

Photovoltaic sunshade based on perovskite solar cells

The phovoltaic sunshade was deployed on the facade of a factory owned by Polish aluminum system provider Aliplast. The movement of the PV blinds is regulated by a controlling system linked to a weather station installed on the roof.

Goldi Solar unveils M10 modules

The Indian manufacturer has introduced the HELOC̣ Pro series featuring mono-facial and bifacial modules based on M10 (182mm x 182mm) wafer size.

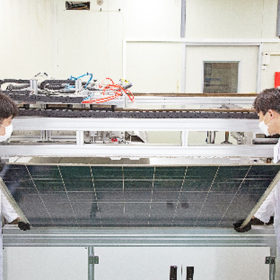

JinkoSolar unveils details of its TopCon 620W bifacial solar panel

The Tiger Neo panel has a power conversion efficiency of up to 22.1% and a temperature coefficient of -0.30% per Celsius degree. The product is made with 182mm wafers, half-cut cells, and has a power output ranging from 590 to 620 W.

Loom Solar unveils 440W/530W bifacial modules

The Indian manufacturer has launched the Shark series bifacial panels for rooftop solar projects. The nine-busbar panels have a power output of 440W-530W with front-side efficiency ranging from 20 to 21% and rear-side gain of up to 20%.

Fraunhofer CSP develops repair process for PERC solar cells

The performance of the solar cell contacts can be improved with laser-assisted current treatment. The process does not damage the solar cells but only optimizes faulty semiconductor-metal contacts.

Green roof improves solar panel efficiency by 3.6% on average

The comparison of two solar cladded roofs in Sydney, Australia, one bare beneath its panels and the other adorned with native grasses and plants, has found the panels on the green roof were, on average, 3.63% more efficient, producing an average daily output 13% greater than the conventional roof. The improvements are believed to stem from the lower temperatures on the green roof, thanks to its plants – which also provided a plethora of additional benefits.

Novel PV module recycling tech from South Korea

Developed by the Korea Institute of Energy Research (KIER), the “non-destructive” technology is claimed to enable the recovery of 100% of a module’s glass and to allow the reuse of silicon for producing new solar cells with an efficiency of 20.05%.

Australian researchers develop bifacial solar cell with 96.3% bifacial factor

Australian National University researchers claim to have set a world record for bifacial solar cell efficiency that they say could boost the energy output of solar farms by 30%.