Xbattery launches 5 kWh scalable energy storage system for residential, small office use

Hyderabad-based startup Xbattery has launched a 5 kWh scalable energy storage system (ESS) for homes and small offices. The lithium iron phosphate (LFP)-based system can be scaled up to 15 kWh by adding additional battery units.

TEXMiN, Russia’s GIREDMET ink pact on rare earth and critical mineral technologies

The TEXMiN Foundation, IIT (ISM) Dhanbad, has signed an MoU with GIREDMET State Research and Design Institute of Rare Metal Industry, Russia, to collaborate on rare earth processing, critical minerals, advanced materials, and translational research across the mining value chain. The partnership will also focus on hydrometallurgical recycling technologies for lithium-ion batteries to recover valuable metals.

Maxvolt Energy partners IIT Roorkee to develop AI‑driven BMS for energy storage and electric mobility solutions

Maxvolt Energy, a Ghaziabad-based lithium battery pack manufacturer, has signed a memorandum of understanding (MoU) with the Indian Institute of Technology (IIT) Roorkee to jointly develop an AI‑driven battery management system (AI‑BMS) for next‑generation energy storage and electric mobility solutions.

Comparing safety profiles of lithium-ion, sodium-ion and solid-state batteries

New research finds that battery safety rankings are not universal but highly dependent on application scenarios, and shows that LFP batteries can emit high levels of hydrogen fluoride, challenging their reputation as the “safest” chemistry.

India’s FY2027 budget shifts focus from renewable deployment to manufacturing, but execution challenges persist, says Wood Mackenzie

Clean energy spending rises 40% to $5 billion as government prioritises CCUS, domestic supply chains and strategic manufacturing. However, execution delays and underutilisation of allocated funds could limit the near-term impact, according to an analysis by Wood Mackenzie.

India’s Union Budget 2026–27 removes customs duty on solar glass inputs, lithium battery cell machinery, and critical minerals processing equipment

India’s Union Budget 2026–27 extends basic customs duty (BCD) exemptions on the import of capital goods used for lithium-ion cell production for battery energy storage systems (BESS), as well as capital goods required for processing critical minerals. It also removes the 7.5% BCD on sodium antimonate used in solar glass manufacturing.

Pre-Budget 2026: Solar and storage industry calls for tax reforms, PLI expansion, and circular economy push

Ahead of the presentation of the Union Budget 2026–27, stakeholders across India’s solar and energy storage ecosystem have urged the government to focus on tax reforms, expansion of production-linked incentive (PLI) schemes with targeted allocations, faster viability gap funding (VGF) disbursements, additional funding for residential rooftop solar, improved access to long-term and affordable green finance, and a stronger push for circular economy initiatives and grid modernisation.

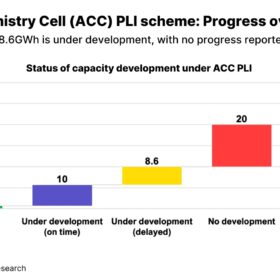

India’s PLI scheme achieves just 2.8% of targeted 50 GWh battery manufacturing capacity so far

Despite strong industry interest, India’s Advanced Chemistry Cell Production Linked Incentive (ACC PLI) scheme, launched in October 2021, is yet to translate policy ambition into realised capacity. As of October 2025, only 2.8% (1.4 GWh) of the targeted 50 GWh capacity has been commissioned within the stipulated timeline, entirely by Ola Electric—according to a new report by JMK Research and the Institute for Energy Economics and Financial Analysis (IEEFA).

ChemVolt Global announces 5 GWh lithium-ion cell manufacturing project in Andhra Pradesh

Kuldeep Gupta-led ChemVolt Global has signed a memorandum of understanding (MoU) with the Government of Andhra Pradesh to establish a 5 GWh lithium-ion cell manufacturing gigafactory in the state, with a planned investment of INR 2,500 crore.

Australia betting on new ‘strategic reserve’ to loosen China’s grip on critical minerals

The federal government has unveiled new details of its plan to create a $1.2 billion critical mineral reserve. Three minerals will initially be the focus: antimony, gallium and rare earths (a group of 17 different elements).