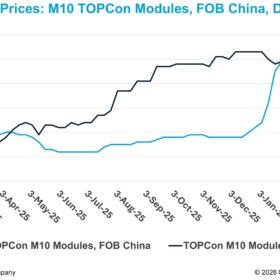

China TOPCon module prices edge higher as March cargoes clear

In a new weekly update for pv magazine, OPIS, a Dow Jones company, provides a quick look at the main price trends in the global PV industry.

Why tech-enabled, solar-compatible BESS will power the next energy boom

The next clean-energy boom will be driven not only by renewable generation but by intelligent storage. Tech-enabled, solar-compatible battery energy storage systems (BESS) will make clean energy predictable, resilient, and commercially viable at scale.

European Commission proposes Made in EU requirements for solar inverters, cells

The Industrial Accelerator Act says solar projects awarded through public procurements or other public support schemes would need to feature Europe-made solar inverters and cells within three years after the act becomes law. For battery energy storage systems, similar requirements would be introduced using a phased approach from one year after the act enters force.

All European sodium-ion battery manufacturers at a glance

The European Economic and Social Committee (EESC) will place sodium batteries at the center of its work on the EU’s industrial strategy and is calling for swift action. pv magazine has compiled a list of manufacturers developing this technology in Europe.

Siemens Energy India Q1 profit rises 34.9% to INR 313 crore

Siemens Energy India Ltd has reported a 26% year-on-year increase in revenue to INR 1,911 crore and a 34.9% rise in profit after tax to INR 313 crore for the quarter ended December 2025 (Q1 FY2026). The company’s order backlog expanded 37.6% to INR 17,599 crore.

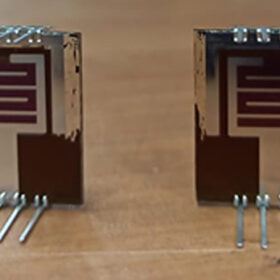

Trina Solar unveils 485 W TOPCon PV panel with 24.3% efficiency

The Chinese manufacturer has launched its third-generation Vertex S+ G3 dual-glass TOPCon modules for residential and commercial applications. The new products feature upgraded module architecture and a temperature coefficient if -0.26% per C.

Delta Electronics India, TNSDC launch a Centre of Excellence in Robotics & PLC Automation

Delta Electronics India, in collaboration with the Tamil Nadu Skill Development Corp. (TNSDC), has inaugurated a Centre of Excellence (CoE) in Robotics and PLC Automation at the College of Engineering, Bargur, in Krishnagiri district, Tamil Nadu.

Beyond the panels: How India’s solar growth and PM-KUSUM are redefining the grid

While policy discussions focus on solar tariffs and farmer incentives, we see a different challenge emerging on the factory floor: Infrastructure Redefinition. The humble transformer is being asked to do things it was never originally designed to do.

Group Surya commissions 500 MW G12R solar module line in Odisha

Group Surya has commissioned a 500 MW G12R solar module production line in the Indian state of Odisha. The fully automated facility will be expanded to 1 GW within four to five months.

The Hydrogen Stream: India launches Hydrogen Valley Innovation Cluster under National Green Hydrogen Mission

India has launched the Hydrogen Valley Innovation Cluster under the National Green Hydrogen Mission to accelerate the transition of green hydrogen technologies from laboratory research to industrial deployment.