A group of researchers from Chinese PV module maker DAS Solar has created a new methodology to detect hot spot risks in TOPCon solar cells and modules based on back-contact (BC) architecture.

“We found that the inherently low shunt resistance of TOPCon BC cells renders the conventional inflection point method specified in IEC 61215 MQT09 ineffective in identifying the hot-spot risks of the modules, which in turn leads to an evaluation process that is both time-consuming and less accurate,” the research’s lead author, Dengyuan Song, told pv magazine. “To address this technical bottleneck, our research team proposed a two-level collaborative equivalent circuit model for substring-module systems, which directly resolves the non-inflection-point issue encountered in IEC 61215 MQT09 testing caused by the low shunt resistance of TOPCon BC cells.”

Image: DAS Solar

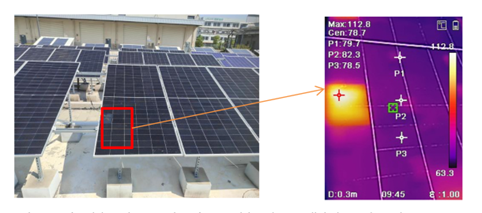

The scientists constructed dedicated equivalent circuit model at the substring level to simulate power dissipation characteristics under diverse partial-shading conditions, establishing a direct quantitative correlation between hot-spot power density and temperature rise. “The accuracy and robustness of the proposed model were comprehensively validated through dual verification of indoor controlled experiments and outdoor field measurements,” said Song. “The results demonstrated that the predicted temperature variation trends were in close agreement with real-world test data, confirming the practical reliability and industrial applicability of the proposed method.”

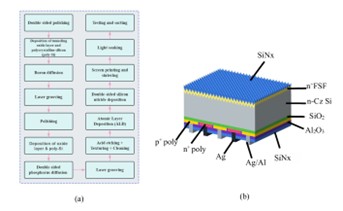

For their experiments and experimental validation, the scientists chose TOPCon BC solar cells with a area of 191.37 cm² from the same production line, ensuing consistent manufacturing parameters. The cells were categorized according to the following criteria: 0.1% efficiency interval, 5 mV open-circuit voltage interval, and uniform film color. Cells showing abnormal photoluminescence (PL), electroluminescence (EL), or appearance defects were excluded. Qualified cells were subjected to the standard TOPCon BC module fabrication process, including ink printing, solder paste application, series welding, lamination stacking, lamination curing, EL testing, frame assembly, junction box installation, and final current-voltage (I-V) testing.

As encapsulation materials, the scientists used coated semi-tempered ultra-white embossed front glass with thickness of 2.0 mm and high transmittance, an ethylene-vinyl acetate (EVA) film, and uncoated semi-tempered ultra-white embossed rear glass with a thickness of 2.0 mm featuring three middle holes and grid glazing.

“All other components were of the same model and batch,” Song specified. “To ensure experimental consistency, all modules were fabricated on the same production line under identical process parameters, resulting in three modules designated as A, B, and C.”

Image: DAS Solar

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.