With the rapid growth of solar photovoltaics, module reliability has become a central issue for the industry. Among the quality problems that have emerged recently, spontaneous glass breakage is attracting increasing attention. Long considered isolated incidents, glass breakages are now becoming more frequent, revealing the limitations of certain industrial choices and the need for heightened vigilance.

The rise of solar energy has been accompanied by the constant evolution of technologies and manufacturing processes. To meet global demand and reduce costs, many manufacturers have opted for larger, more powerful, but also lighter modules. A lighter module has the undeniable advantage of reducing the weight on structures, and therefore the costs of the building structure. With glass representing more than half the module’s weight, this quest for lightness has naturally led to the use of increasingly thinner glass.

While this development allows for lighter structures and simplifies logistics, it has consequences for the robustness of the modules. Indeed, thinner glass, even if tempered, is more susceptible to the mechanical and thermal stresses encountered throughout the module’s lifespan, from manufacturing to on-site operation.

Increase in cases of fragility

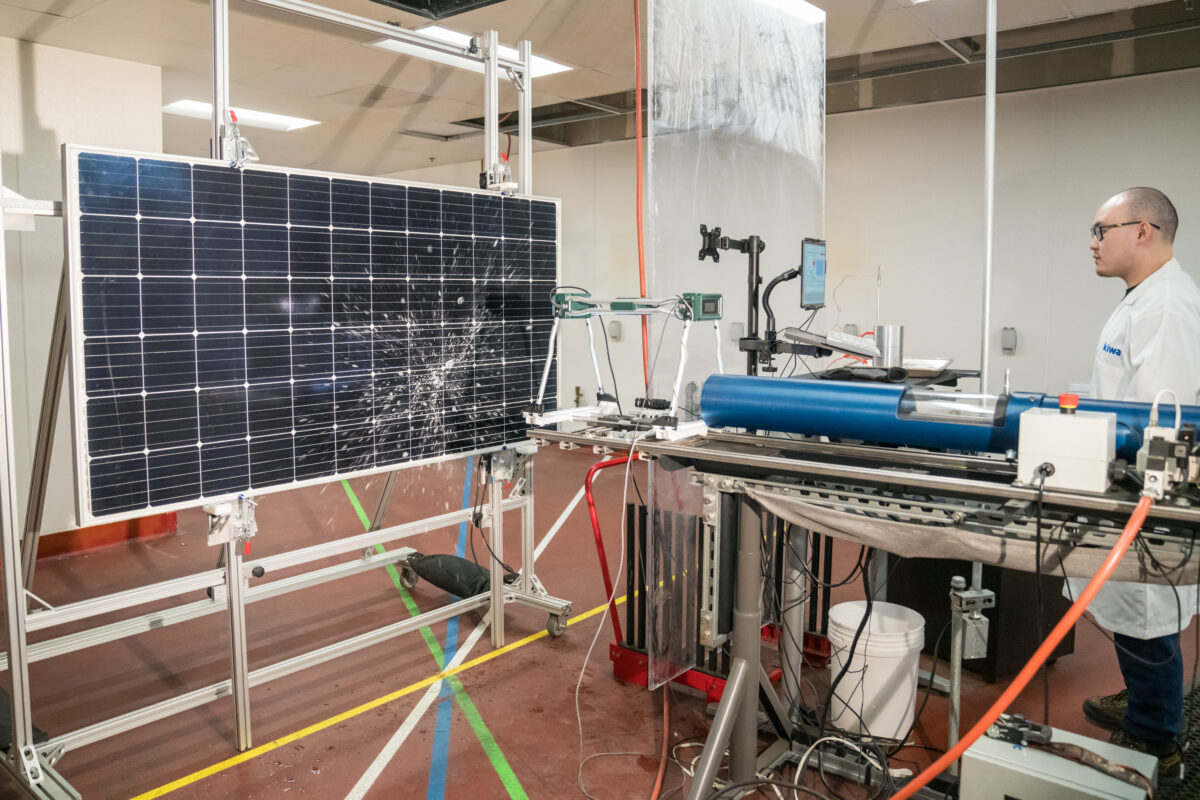

Independent quality tests, such as those conducted by RETC or Kiwa PVEL, indicate increased fragility in the modules (Kiwa PVEL’s 2025 scorecard indicates that 83% of manufacturers failed at least one module reliability test, compared to 66% in 2024). This trend is also supported by feedback from the field. Cases of cracked or broken modules, sometimes just weeks after installation, occur without any external shock or exceptional weather event being implicated.

Reduced impact resistance also increases breakage during module installation and maintenance, particularly when cutting vegetation with stones, which can damage the panels. In some projects, the breakage rate reaches significant levels, leading to production losses, replacement costs, and safety risks for personnel. It’s important to remember that a broken module is no longer a Class 4 live appliance (like a washing machine, for example), and therefore poses a risk of electrocution to on-site personnel.

Diagnosing these defects is complex: microcracks, often invisible to the naked eye, can propagate under the influence of temperature or humidity variations, eventually causing a sudden break in the glass. Their detection requires thorough, lengthy, and costly inspections, and delayed identification can lead to water infiltration, resulting in insulation defects, reduced availability and efficiency, and even fire hazards.

Faced with this reality, the question of standards and certification tests arises. Current protocols are designed to guarantee the robustness of modules under standard conditions and sometimes struggle to reflect the diversity of constraints encountered in the field. New-generation modules, with ever-larger formats, are subjected to increased mechanical and thermal stresses, for which traditional safety margins are no longer always sufficient. This situation calls for a reassessment of testing methods to incorporate scenarios more representative of real-world operating conditions, with a proposed test sequence in addition to individual tests, as per IEC 61215:2021.

Rigorous quality control procedures

Beyond purely technical aspects, it is no longer enough to rely on standard certifications or guarantees: buyers, whether developers, operators, or investors, must independently verify the conformity and robustness of the modules they integrate into their projects. This involves the implementation of rigorous quality control procedures, including an audit of the manufacturing plant and in particular the lamination conditions as well as additional sampling tests before the start of production, during production and throughout the supply chain.

Visual inspection, performance testing on samples, verification of material traceability, and monitoring of transport conditions can help limit defect risk and identify potential problems before modules are deployed. In light of recent issues affecting double-glass modules using 2 mm glass, both glass suppliers and module manufacturers should also implement or strengthen formal glass quality control plans.

Such plans should include:

-

Incoming inspection of raw glass sheets before lamination, including surface checks under oblique lighting and magnification to detect micro-defects

-

Non-destructive surface testing, such as surface stress measurement, optical distortion mapping, or photoelastic analysis, to identify tempering flaws or uneven stress

-

Clear acceptance criteria defining the size, type, and location of permissible defects

Stricter quality requirements are essential to maintaining the profitability and long-term performance of solar assets. Ongoing price pressure in the module market continues to push manufacturers to reduce costs, sometimes at the expense of component quality, making independent quality control by buyers increasingly important. By raising their standards and sharing best practices, project developers and investors can help improve reliability across the industry.

About the authors:

Gauthier Dambrine is a project manager at Skyray with 15 years of experience in the wind and solar PV sectors. He has held technical roles in the design, development, certification, and installation of solar tracking systems across Europe, the Middle East, Africa, and Asia.

Alexia Chappond has worked in the renewable energy sector since 2010, covering project development, construction, and operation. In recent years, she has focused on technical due diligence, performance analysis, construction supervision, and commissioning of PV power plants.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.