India’s power landscape is undergoing a structural inflection point where domestic manufacturing has shifted from a supporting function to a central pillar of national energy security. The country’s installed capacity crossing 505 GW in 2025—of which non-fossil sources now contribute over 50%—signals not just a transition in energy mix, but a transition in strategic capability. As India moves deeper into a high-growth, high-demand decade, power security is no longer defined merely by generation capacity; it hinges on how much of that capacity can be built, supplied, and maintained through indigenous industry.

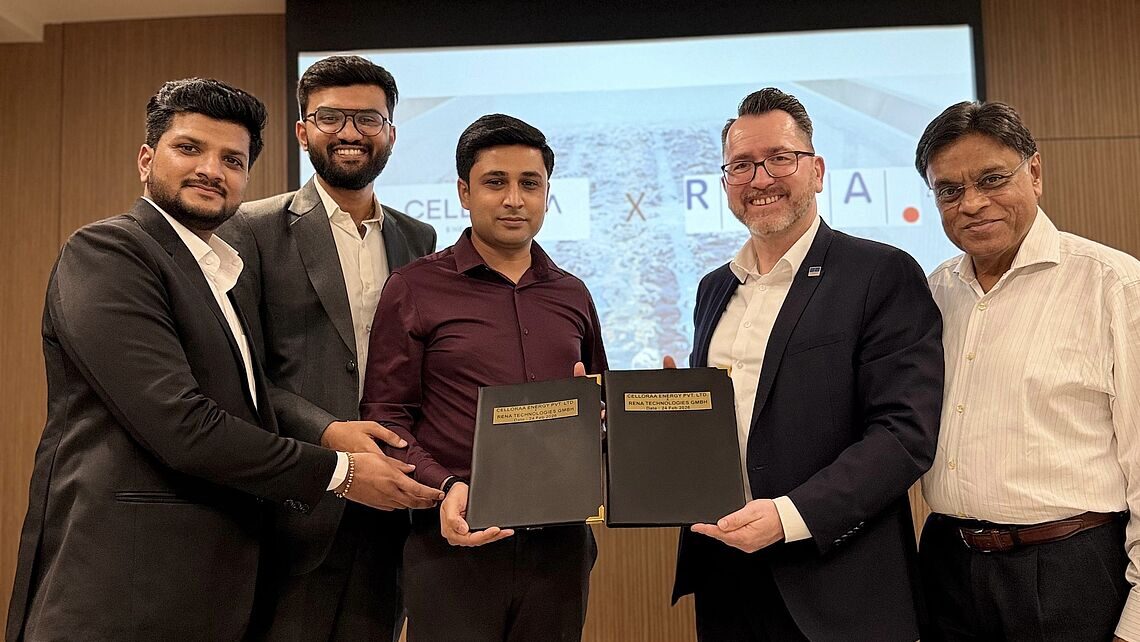

A defining shift has occurred in solar energy. Installed solar capacity has surged from roughly 3 GW in 2014 to nearly 130 GW by late 2025, supported by domestic module manufacturing that now exceeds 144 GW and is projected to cross 165 GW by 2027. This expansion is a direct outcome of policy mechanisms such as the production-linked incentive (PLI) scheme, which has attracted over INR 52,000 crore in investment and created tens of thousands of jobs across multiple states. The emergence of wafer, ingot, cell, and module manufacturing within India marks a decisive departure from earlier years when dependence on imported Chinese modules posed both cost and supply risks.

Battery manufacturing has followed a similar trajectory. As renewable penetration rises, so does the need for storage to stabilize grid performance and enable round-the-clock solar and wind supply. India’s ACC battery PLI scheme aims for 50 GWh of advanced cell manufacturing capacity, with investments under the broader automotive and ACC PLI already exceeding INR 35,000 crore. Commissioned units—though still early in scale—signal a foundational move toward domestic capacity in a segment long dominated by foreign suppliers. Beyond mobility, these batteries will form the backbone of grid-scale storage, rural electrification solutions, and renewable balancing reserves, making domestic cell production critical for both economic resilience and energy reliability.

On the grid side, India is expanding its transmission and distribution backbone at a pace that mirrors its generation growth. In FY 2024–25 alone, over 86,000 MVA of transformation capacity was added, and the total high-voltage AC transformation capacity stands above 1,300 GVA. The electrical equipment market—valued at more than US$80 billion in 2025—is buoyed by double-digit growth in transformers, switchgear, and power cables. This is no longer a market heavily reliant on imports; domestic manufacturers now support large segments of national expansion, even though certain sensitive components continue to be sourced from a concentrated set of foreign suppliers. The direction of travel, however, is clear: domestic electrical equipment is increasingly driving India’s grid modernization and the build-out of renewable corridors.

Viewed together, these shifts reveal two overarching conclusions. First, India is reducing structural dependence on foreign supply chains by manufacturing solar modules, batteries, transformers, and other critical components domestically at unprecedented scale. Second, this domestic manufacturing push is now indispensable for India’s renewable expansion; without it, bottlenecks, higher costs, and geopolitical disruptions would slow progress toward climate goals. Power security in India is therefore increasingly a function of industrial capability, not just energy policy. As domestic manufacturing deepens across the entire energy value chain, India moves closer to a future where clean energy growth and national energy resilience reinforce one another.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.