French startup DOTSun has unveiled an on‑site repair solution for solar panels suffering from backsheet degradation.

The new system, called DOTSun Extended Life, is compatible with all major backsheet types, including polyamide (PA), polyvinylidene fluoride (PVDF), and polyethylene terephthalate (PET).

“The on-site repair solution will be commercialized this quarter and is designed to extend the service life of existing panels while minimizing operational downtime,” Stephan Padlewski, founding partner at DOTSun, told pv magazine. “Our initial focus is on greenhouses, rooftops, and small ground-mounted systems, with up to 1,000–2,000 panels that can be repaired directly on-site.”

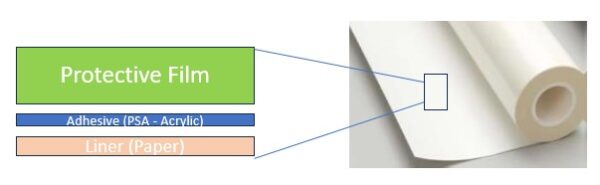

The repair process involves applying a hydrolysis- and UV‑resistant adhesive film to the rear side of the module, restoring electrical insulation and long-term durability. The protective film is 125 µm thick and uses a pressure-sensitive adhesive to ensure strong bonding to degraded PA, PVDF, and PET surfaces, according to DOTSun. It is manufactured in France by high-performance materials provider Addev Materials.

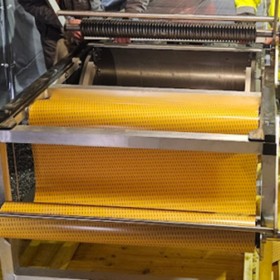

The film is also fully compatible with DOTSun’s proprietary lamination equipment, which operates manually without the need for external power. The laminator can accommodate panels up to 1,100 mm × 2,100 mm and achieve a throughput of up to 10 panels per hour per device.

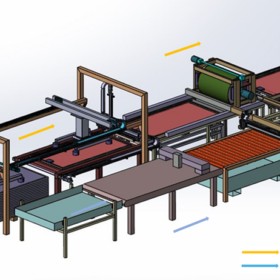

“For larger volumes, DOTSun has developed an industrial-scale laminator capable of repairing and testing around 100 panels per hour, enabling the processing of significantly higher quantities of modules to be repaired, remanufactured, and reused,” the company’s co-founder, Denis Duyrat, said. “This industrial repair solution is planned for deployment toward the end of 2027, contingent on the successful completion of a financing round targeted for the first half of 2026.”

Before proceeding with repearing, the French company conducts a comprehensive technical audit to assess PV plant performance at the module level. The audit identifies early signs of backsheet degradation and determines whether panels are repairable based on the severity of damage and overall electrical performance. Panels showing reversible degradation can be repaired and reinstalled at the same site. Modules with irreversible degradation must be replaced.

The repair workflow begins with dismantling the affected modules and transporting them to a mobile on‑site repair unit. Up to 80 panels per day can be cleaned and laminated per line, with multiple lines available to increase throughput and capacity.

On-site, a dedicated workshop shelter is set up to facilitate the repair process and ensure that all operations are carried out in a controlled environment. This shelter is specifically designed to accommodate four main stages of the procedure.

The preparation stage involves a thorough visual inspection and cleaning of the panels using methods such as vacuuming, brushing, and wiping. Next, during the lamination stage, DOTSun’s proprietary protective film is applied uniformly across the entire backsheet, enhancing the panel’s durability. The finishing stage follows, where the edges of the panel and the junction box are sealed with a UV- and moisture-resistant insulating coating, providing additional protection against environmental factors. Finally, the inspection stage ensures quality control through a final visual check and the application of a new label on the repaired module.

Throughout the process, dismantled panels are carefully stacked in accordance with their original string layout, ensuring proper organization and ease of reassembly. After inspection and labeling, panels can be immediately reinstalled on-site.

In early 2024, DOTSun completed a proof‑of‑concept project in France, monitoring the repaired modules both visually and electrically. The company partnered with French industrial conglomerate Sicame Group to deploy a string‑level monitoring system, improving performance tracking granularity.

“Audit costs for clients, as well as for state‑of‑the‑art performance analyses of PV plants, are charged on a per‑day basis. For utility‑scale power plants, an audit typically ranges between €1.500 ($1,750) and €2,000 per MW,” Padlewsky explained. “Our on‑site repair benchmark is €15–20 cents per W, representing a 40–60% saving compared to purchasing new panels with similar historical characteristics. It is also increasingly difficult to source new 180 W or 245 W modules, as current mass production focuses on panels above 500 W, with entirely different dimensions and weights.”

“Off‑site repair is naturally more cost‑effective, and our benchmark is to remain 25–40% cheaper than new Chinese panels—without even comparing to European‑made modules, which are significantly more expensive,” he went on to say. “To date, all audits are carried out by DOTSun, although we may consider outsourcing part of this activity in the future. However, it remains highly unlikely that we would outsource an audit when it serves as a preliminary step toward a repair campaign.”

DOTSun was founded in 2022 and is based in Bagnols-en-Forêt, in France’s southern Var department. It was recently awarded the Green Fund for Territories of Industry in 2025 by French environmental agency Ademe and Prefecture of the South PACA region.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.