Researchers at the Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) in Germany have, for the first time, applied the so-called mask-and-plate front-metallization approach to the development of perovskite-silicon tandem solar cells.

“The novelty of this work is threefold: first, we achieve very small feature sizes of the copper electrodes as small as 15 µm with an aspect ratio of around 1 by optimized inkjet printing of the plating resist,” the research’s corresponding author, Jörg Schube, told pv magazine. “Secondly, we found a way to directly deposit the copper electrodes on ITO-covered substrates with sufficiently high mechanical adhesion. Thirdly, we provide a proof-of-principle that mask and plate metallization is applicable to perovskite silicon tandem solar cells without significantly damaging the perovskite layer stack.“

“In recent years, we have successfully demonstrated mask and plate as a cost-efficient alternative to traditional lithography in III-V compound–based solar cells. This breakthrough holds promise far beyond photovoltaics,” said co-author Roman Keding. “The same approach could improve lithography-dependent applications such as silicon carbide (SiC) and Si-based power chips towards higher productivity and resource efficiency. Now we see tremendous potential to explore this method, together with manufacturers across diverse sectors.”

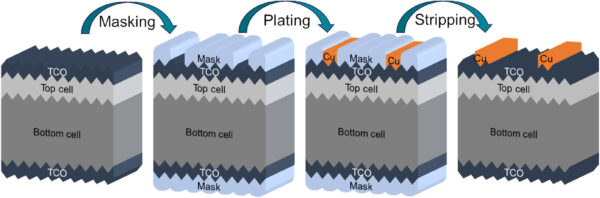

Using the mask and plate approach, ultra-fine metal contacts can be formed on solar cells by first inkjet-printing a precise resist “mask” with narrow openings and then electroplating metals such as copper or nickel. This enables extremely narrow fingers, reducing shading and improving efficiency while avoiding costly photolithography. Because the process can use copper instead of silver, it significantly lowers material costs and improves resource scalability.

Using the mask and plate method and industrial production equipment, the researchers fabricated a copper-metallized, M6-sized heterojunction solar cell with an efficiency of 22.5%. This efficiency level was found to be slightly higher than that of a comparable silver-metallized device.

They attributed the efficiency gain to reduced shading losses from the copper metallization and strong mechanical adhesion of the copper contacts, achieved through a plasma processing step applied between mask printing and galvanic metal deposition.

Using lab-scale equipment and the same technique, the team also produced a 1.21 cm² perovskite-silicon tandem solar cell with an HJT bottom cell. Under standard illumination, it achieved a power conversion efficiency of 19.35%, reportedly the highest value yet reached for this cell type using galvanic front metallization.

“This work further demonstrates the applicability of mask and plate copper metallization to 1.21 cm2-sized perovskite silicon tandem solar cells without significant damage. It can, thus, be an enabler for silver-free industrial metallization of next-generation solar cells,” the academics concluded. “Further work is necessary to confirm the finding, that it doesn’t harm perovskite-silicon tandem solar cells when utilized in mask and plate metallization process sequence.”

Their findings were presented in “Mask and plate copper metallization for silicon heterojunction and perovskite silicon tandem solar cells,” published in Solar Energy Materials and Solar Cells.

The Fraunhofer ISE has developed several manufacturing technologies to reduce silver use in solar cells. These include screen printing, FlexTrail printing, gravure printing, and rotary printing.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.