Researchers at Australia’s University of New South Wales (UNSW) have assessed the impact of soldering fluxes on the corrosion of metal contacts in solar cells based on tunnel oxide passivated contact (TOPCon) design under damp-heat (DH) conditions.

The DH test is an accelerated test that tests the reliability of modules under extreme humidity and heat. In its standard form, the PV is placed in a controlled chamber with a temperature of 85 C and humidity of 85% for at least 1,000 h.

“Our study provides PV manufacturers with a fast, low-cost diagnostic to detect soldering-related reliability issues early in production,” the research’s corresponding author, Bram Hoex, told pv magazine. “It also helps the industry reduce warranty claims and performance losses due to moisture-induced corrosion.”

Soldering fluxes are used to remove the oxide from the tab ribbons or bus ribbons during the module assembly process.

The scientists focused their analysis on the so-called “no-clean” fluxes, which do not require cleaning after soldering to simplify the production process. These fluxes remove oxides and create strong metallurgical bonds while leaving minimal, non-conductive residues.

For the testing, they used two commercial fluxes called Flux A and Flux B, with the latter being based on L-malic acid and the former on carboxylic acid. Furthermore, they utilized three commercial TOPCon cells produced via the so-called laser-enhanced contact optimization (LECO) process in 2019, 2022 and 2023.

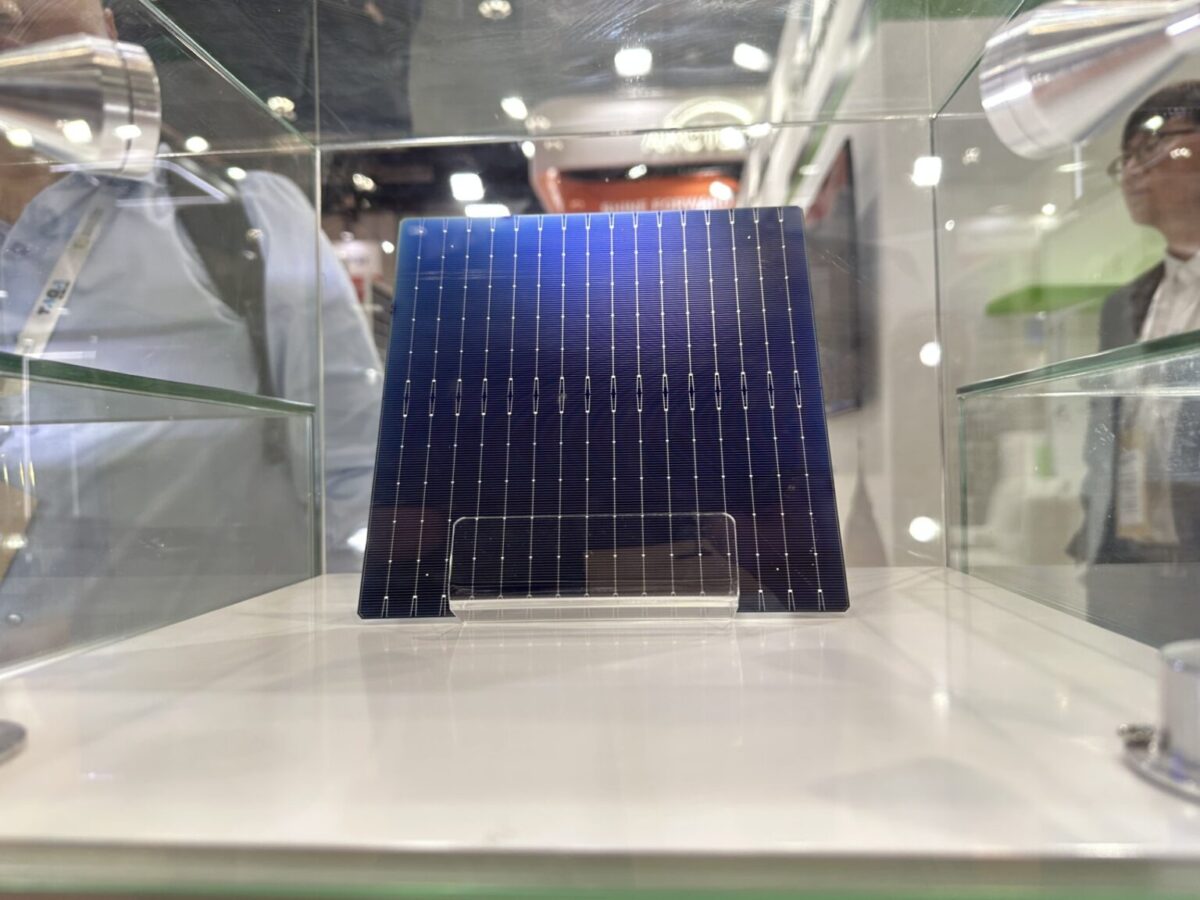

“All three n-type TOPCon cells exhibit a similar structural design, with the front side having a boron-doped (p+) emitter covered by aluminium oxide (Al2O3), and hydrogenated silicon nitride (SiNx), along with an H-pattern silver grid applied by screen printing,” the scientists said, without revealing the name of the manufacturers. “The rear side comprises silicon dioxide (SiO2), phosphorus-doped (n+) polysilicon, SiNx, and a similar H-pattern silver grid.”

The cells were divided into three groups: G1) Flux A exposure on the front side; G2) Flux B exposure on the front side; G3) Flux A exposure on the rear side; G4) Flux B exposure on the rear side; and G5) control group without flux exposure. Fluxes were applied via spraying, with drying being performed on a hot plate at 85 C for up to 10 m.

“Our analysis showed that residues from ‘no-clean’ soldering flux can cause severe corrosion of TOPCon front silver-aluminum (Ag–Al) contacts under DH exposure, increasing series resistance and reducing efficiency,” Hoex said. “Flux A, with halogens, is significantly more corrosive than Flux B, but both cause notable degradation.”

The research team also found that degradation is largely absent on the rear Ag paste, which is more chemically stable, and that denser metallisation structures and lower aluminium content improve corrosion resistance.

As potential solutions to these degradation issues, the academics proposed applying unencapsulated, cell-level DH testing to rapidly identify flux-related risks before module assembly as well as selecting flux formulations with minimal halogens and optimised acid content to reduce corrosion potential.

“We also recommend optimising metallisation paste composition and structure to limit flux infiltration,” Hoex said.

The research’s findings are available in the study “Assessing the impact of solder flux-induced corrosion on TOPCon solar cells solar energy materials and solar cells,” published in Solar Energy Materials and Solar Cells.

In February, researchers from UNSW and Chinese-Canadian PV module maker Canadian Solar investigated the effect of soldering flux on both TOPCon and heterojunction (HJT) solar cells and have ascertained that the choice of this component is key to avoiding potential module failures.

Through this work, the scientists found that power losses in the HJT cells were found to be caused by holes in the metallization layer, which facilitate soldering flux penetration, leading to chemical reactions that degrade performance. Furthermore, this research also ascertained that the ITO layer in HJT cells is highly susceptible to damage from soldering flux.

A few months later, a group of researchers from the Korea Electronics Technology Institute (KETI) investigated how commercially available solder fluxes can corrode indium tin oxide (ITO) electrodes in HJT solar cells and found that there is a significant risk of early degradation during the cell interconnection process.

Previous research by UNSW showed the impact of UV-induced degradation (UVID) in TOPCon cells, degradation mechanisms of industrial TOPCon solar modules encapsulated with ethylene vinyl acetate (EVA) under accelerated damp-heat conditions, as well as the vulnerability of TOPCon solar cells to contact corrosion and three types of TOPCon solar module failures that were never detected in PERC panels.

Furthermore, UNSW scientists investigated sodium-induced degradation of TOPCon solar cells under damp-heat exposure and the role of ‘hidden contaminants’ in the degradation of both TOPCon and heterojunction devices.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.